A stable high-conductivity cu-ge-fe ternary dilute alloy film and its preparation process

A cu-ge-fe, alloy thin film technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve many problems such as increasing solid solubility, reducing electron scattering effect, The effect of keeping the overall structure stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

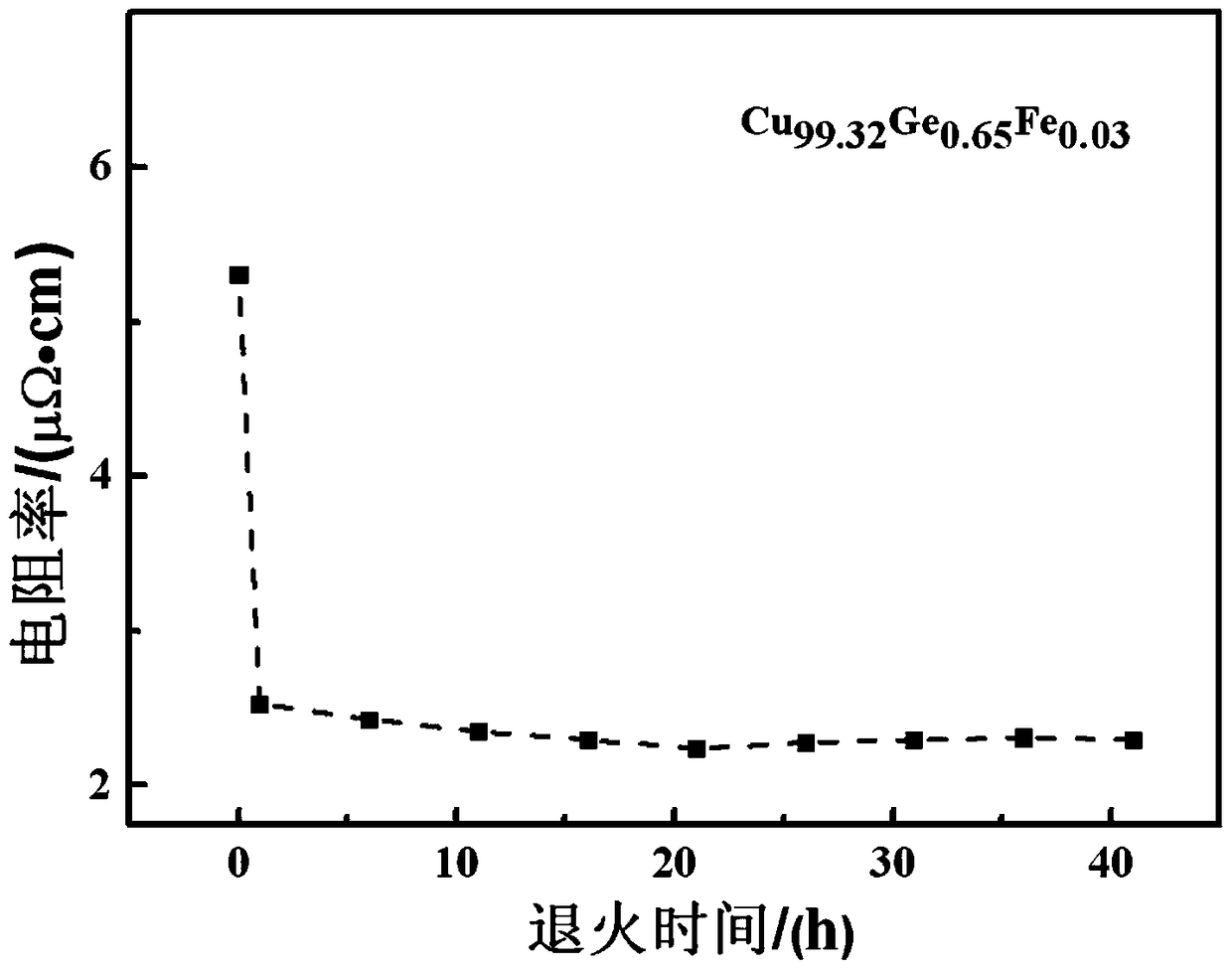

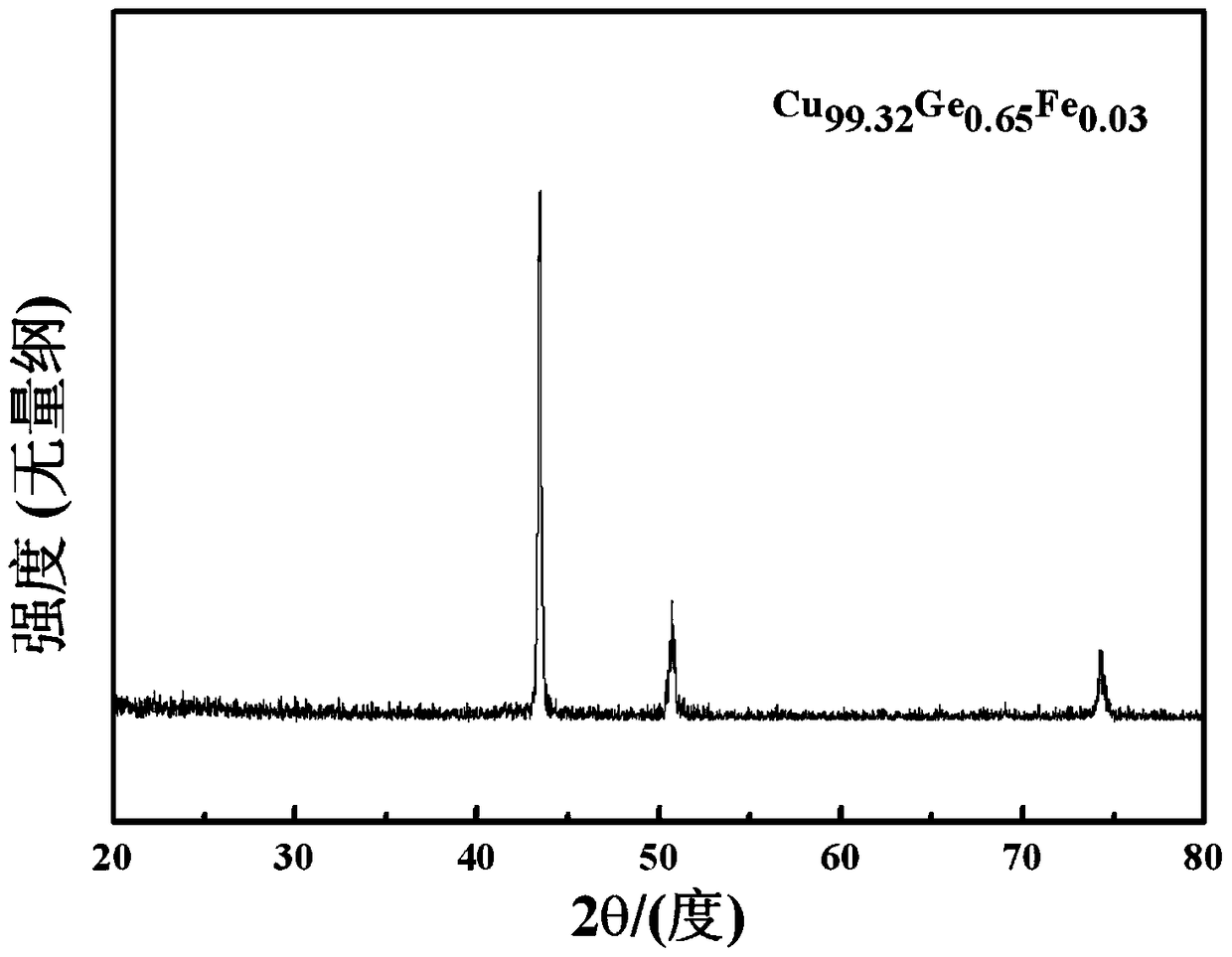

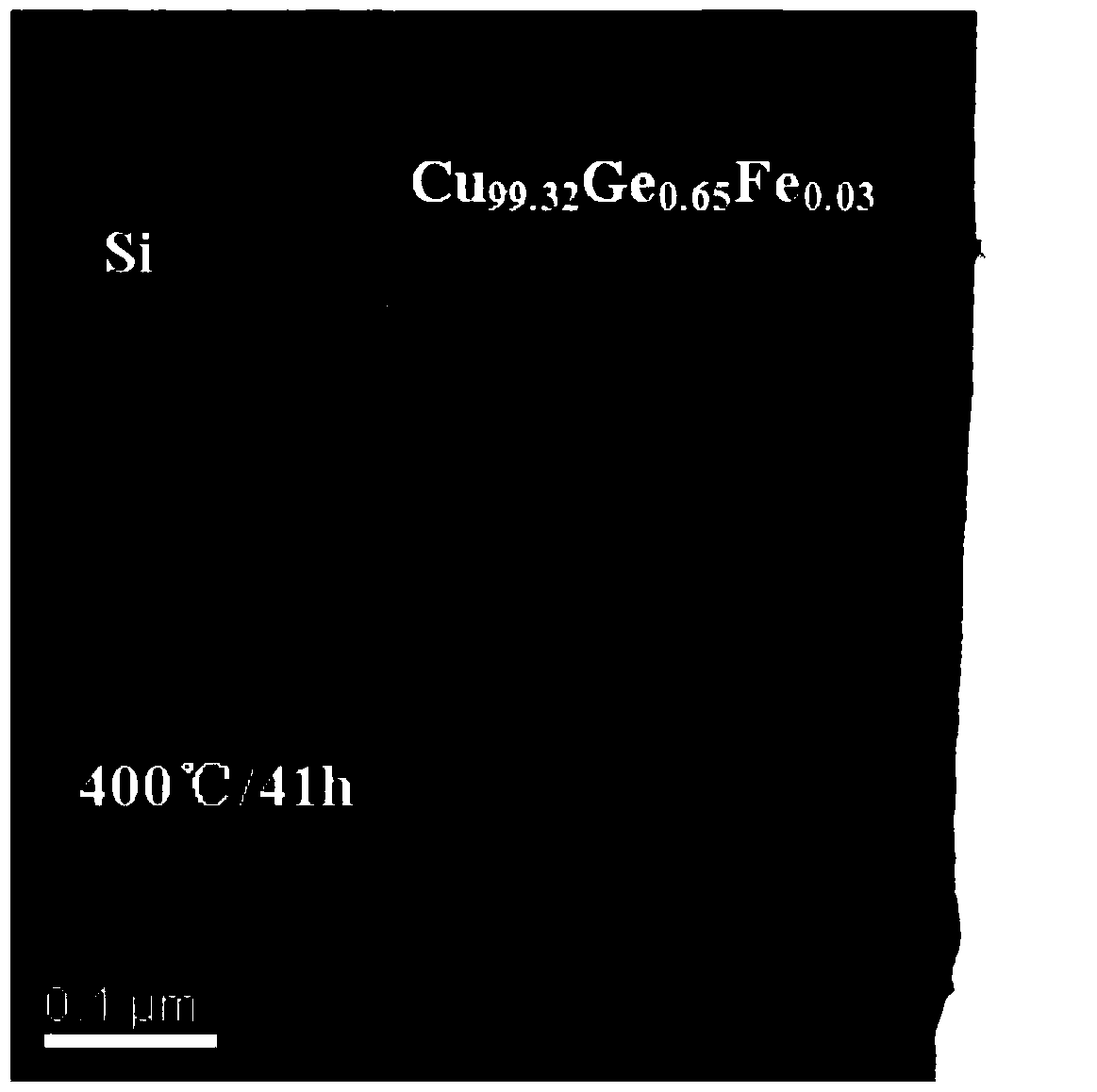

[0023] Embodiment: the following composition is Cu 99.32 Ge 0.65 Fe 0.03 (atomic percent) film as an example to describe the experimental steps:

[0024] First prepare the sample, the process is as follows:

[0025] (1) according to required Ge, Fe atomic percentage content, get the Ge, Fe metal raw material that gets purity to be more than 99.99% and put in the copper crucible of vacuum smelting furnace;

[0026] (2) Pump the air pressure in the furnace to 5~7×10 -3 Pa, close the vacuum chamber, feed high-purity Ar gas into the furnace, and repeatedly smelt the sample raw materials to obtain a Ge-Fe master alloy ingot with uniform composition;

[0027] (3) the alloy ingot in step (2) is prepared into a cylindrical alloy rod with a diameter of 6 mm by copper mold suction casting;

[0028] (4) Cut the alloy rod in step (3) into small alloy sheets with a thickness of 1-1.2 mm, and paste 0.25 alloy sheets in the sputtering area of the high-purity Cu target to make a combin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com