Inorganic compound open-cell foamed vacuum insulation panel core material and preparation method thereof

A vacuum insulation panel and inorganic composite technology, applied in the field of vacuum insulation panel core material and its preparation, can solve the problems of destroying buildings, complex processing technology, high thermal conductivity, etc., achieve production cost control, low thermal conductivity, and low water absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

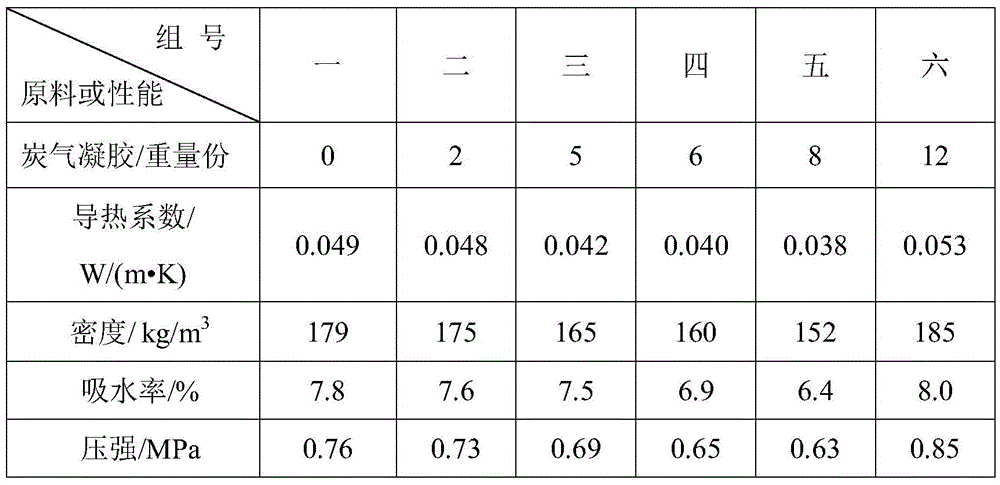

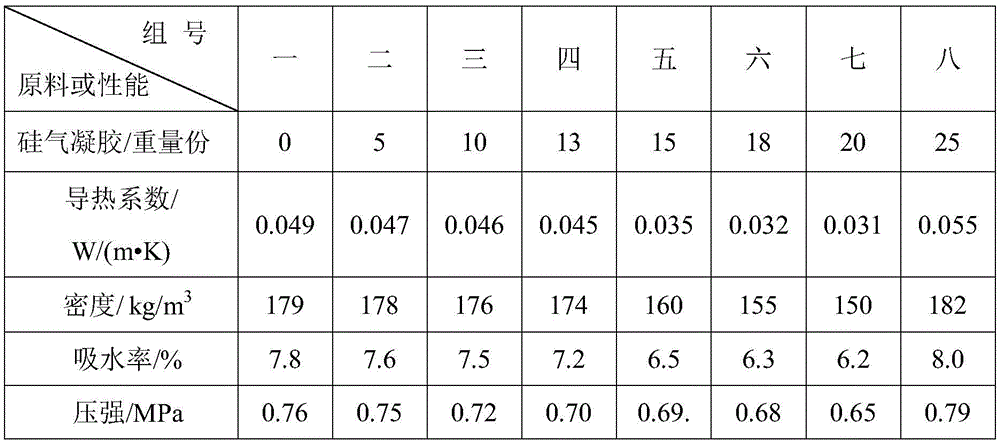

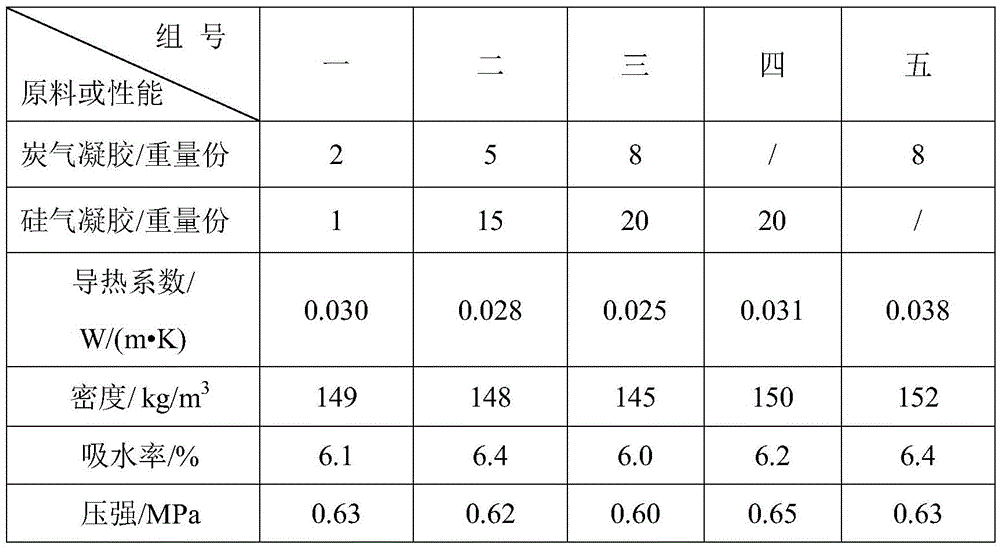

Examples

Embodiment 1

[0020] Raw material components: 80 parts of cement, 15 parts of mineral admixture, 50 parts of opening foaming agent, 0.5 part of foam stabilizer, 0.3 part of water reducing agent, 0.3 part of water repellent, 2 parts of reinforcing fiber and 35 parts of water.

[0021] Production method: select various raw material components by weight, mix them and pour them into molds, place the molds in a drying room at 50°C for 6 hours to make the moisture content of the molds ≤0.5%, and rest for at least 24 hours at 25°C. Then demoulding and curing.

Embodiment 2

[0023] Raw material components: 120 parts of cement, 50 parts of mineral admixture, 100 parts of opening foaming agent, 2 parts of foam stabilizer, 1 part of water reducing agent, 1 part of water repellent, 8 parts of reinforcing fiber and 60 parts of water.

[0024] Production method: select various raw material components by weight, mix them and pour them into molds, place the molds in a drying room at 50°C for 6 hours to make the moisture content of the molds ≤0.5%, and rest for at least 24 hours at 35°C. Then demoulding and curing.

Embodiment 3

[0026] Raw material components: 100 parts of cement, 40 parts of mineral admixture, 60 parts of opening foaming agent, 0.8 part of foam stabilizer, 0.5 part of water reducing agent, 0.5 part of water repellent, 3 parts of reinforcing fiber and 45 parts of water.

[0027] Production method: select various raw material components by weight, mix them and pour them into molds, place the molds in a drying room at 50°C for 6 hours to make the moisture content of the molds ≤ 0.5%, and rest for at least 24 hours at 30°C. Then demoulding and curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com