Thermal insulation reflective stone-like coating and preparation method thereof

A technology of heat insulation reflection and real stone paint, applied in the field of water-based paint for architectural decoration, can solve problems such as hidden safety hazards and self-importance, and achieve the effects of enhanced stability, light self-weight, and smooth batch scraping and construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

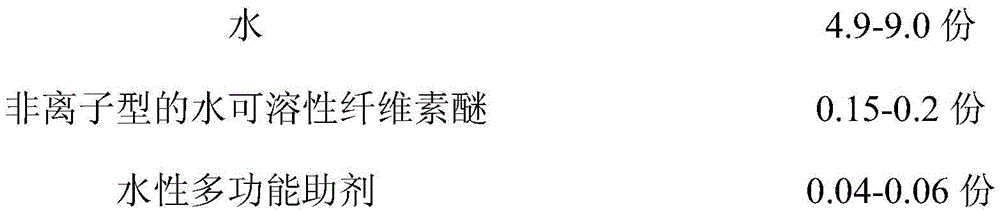

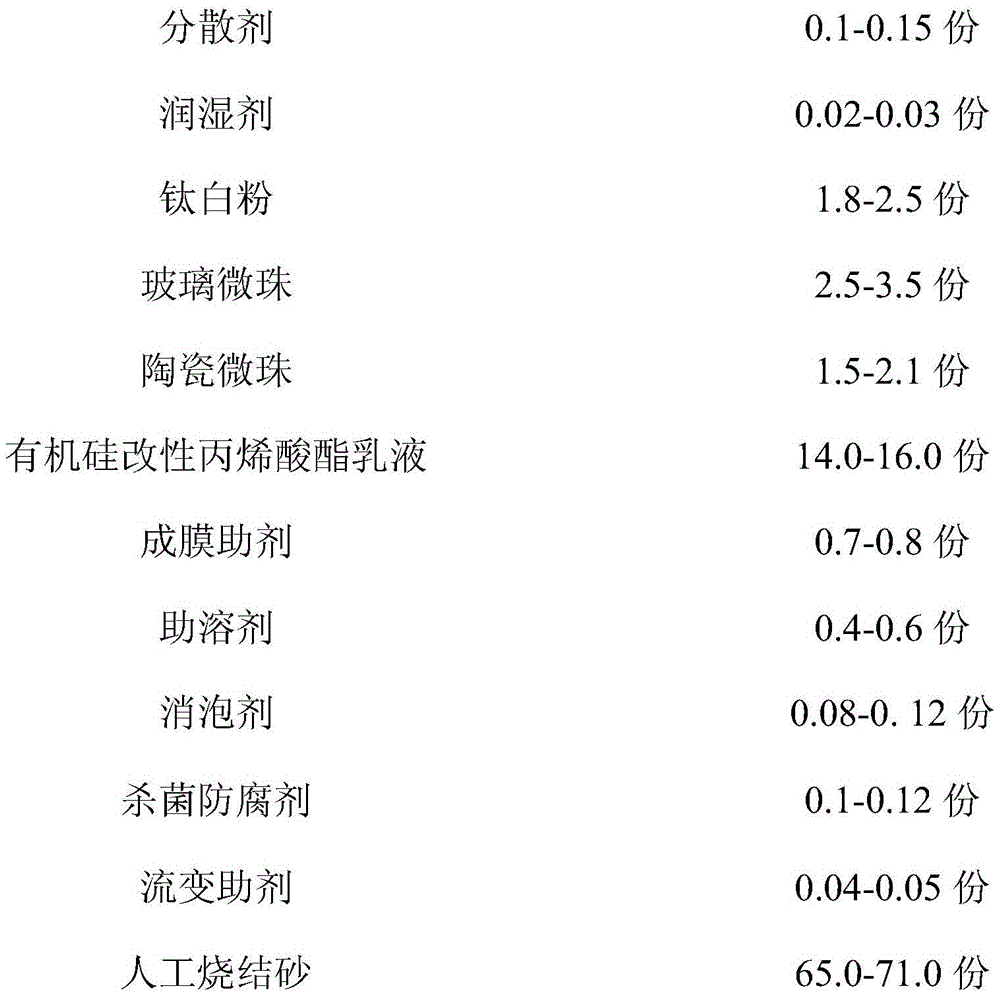

[0036] A heat-insulating reflective real stone paint, which is prepared by the following components in parts by weight:

[0037]

[0038]

[0039] The heat-insulating reflective real stone paint includes the following steps in sequence:

[0040] (1) Add non-ionic water-soluble cellulose ether to the water under stirring at 650r / min and stir for 4min. While stirring, add 2-amino-2-methyl-1-propane with a mass concentration of 95%. Alcohol aqueous solution, then increase the speed to 900r / min and stir for 8min;

[0041] (2) Under stirring at 650r / min, to the mixture prepared in step (1), add polyacrylate sodium salt dispersant, non-ionic surfactant, and surface with a particle size of 0.35 μm through Al 2 O 3 Or SiO 2 After the treated rutile titanium dioxide, reduce the speed to 300r / min, add hollow spherical powdered glass beads with a particle size of 20μm and spherical ceramic beads with a particle size of 6μm while stirring, and continue stirring for 8min after adding;

[0042] (3)...

Embodiment 2

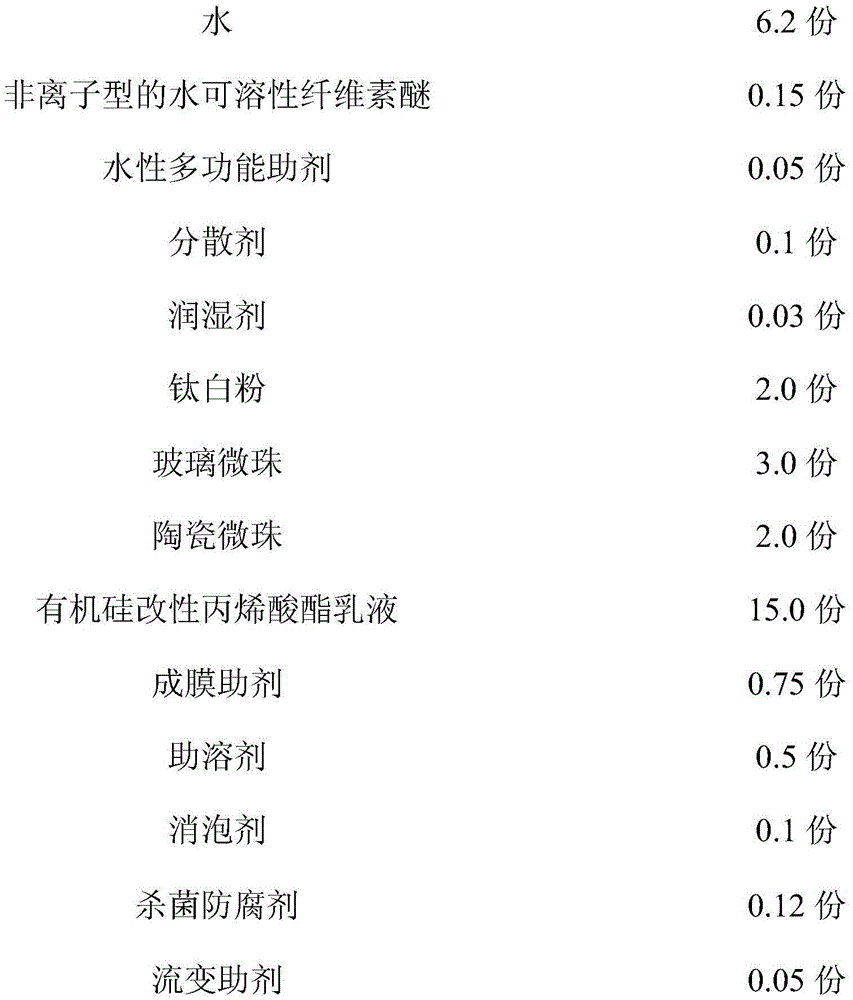

[0045] A heat-insulating reflective real stone paint, which is prepared by the following components in parts by weight:

[0046]

[0047]

[0048] The heat-insulating reflective real stone paint includes the following steps in sequence:

[0049] (1) Add non-ionic water-soluble cellulose ether to the water under stirring at 500r / min and stir for 5min. While stirring, add 2-amino-2-methyl-1-propane with a mass concentration of 90%. Alcohol aqueous solution, then increase the speed to 800r / min and stir for 10min;

[0050] (2) Add polyacrylic acid ammonium salt dispersant, wetting agent, and titanium dioxide to the mixture prepared in step (1) under stirring at 500r / min, then reduce the speed to 500r / min, and add 15μm particle size while stirring Hollow spherical powdery glass beads, spherical ceramic beads with a particle size of 10μm, continue to stir for 5min after adding;

[0051] (3) Add silicone modified acrylate emulsion, film-forming aids, co-solvents, silicone defoamers, bacteri...

Embodiment 3

[0054] A heat-insulating reflective real stone paint, which is prepared by the following components in parts by weight:

[0055]

[0056] The heat-insulating reflective real stone paint includes the following steps in sequence:

[0057] (1) Add non-ionic water-soluble cellulose ether to the water under stirring at 500-750r / min and stir for 3-5min. While stirring, add 2-amino-2-methyl with a mass concentration of 92% -1-propanol aqueous solution, then increase the speed to 800-1000r / min and stir for 5-10min;

[0058] (2) Add dispersant, wetting agent, and titanium dioxide to the mixture prepared in step (1) under stirring at 500-750r / min, then reduce the speed to 250-500r / min, and add particle size while stirring 25μm hollow spherical powdery glass beads, spherical ceramic beads with a particle size of 1μm, continue to stir for 5-10min after adding;

[0059] (3) Under stirring at 250-500r / min, to the mixture prepared in step (2), sequentially add silicone modified acrylate emulsion, f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com