Treatment method and device for high-concentration suspended matter waste water

A treatment method and technology of a treatment device are applied in the treatment of high-concentration suspended solids wastewater and the field of high-concentration suspended solids wastewater treatment devices, which can solve the problem of no solid-liquid separation solution, small recovery of pretreated stone powder, and sand and gravel wastewater. The problem of high concentration can achieve obvious effect of precipitation and concentration, reduce the load of wastewater treatment, and achieve the effect of fast sedimentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

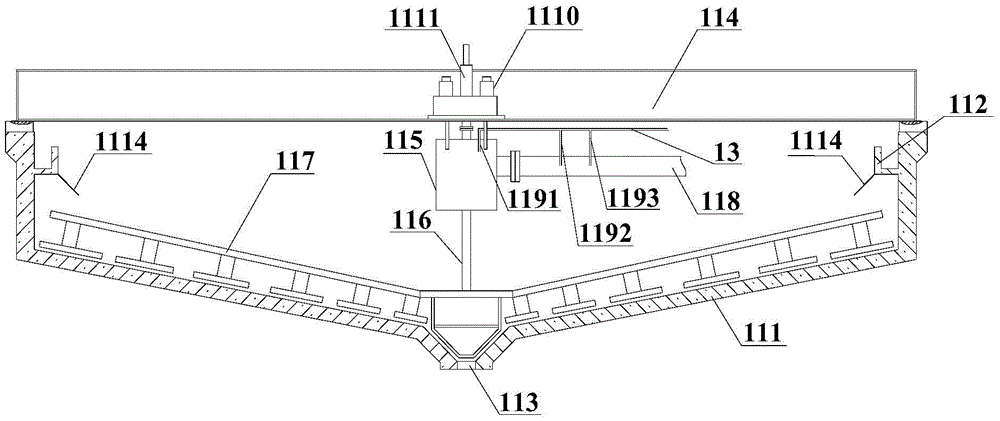

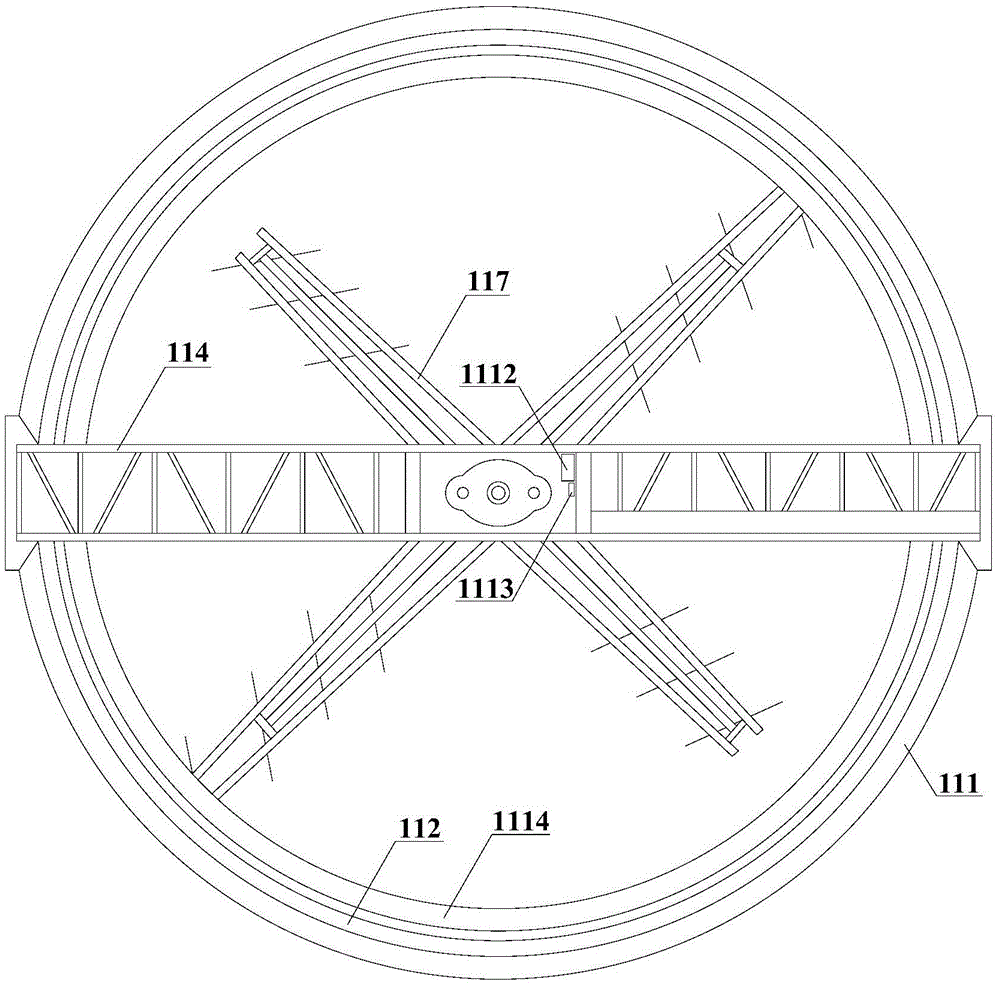

Embodiment 1

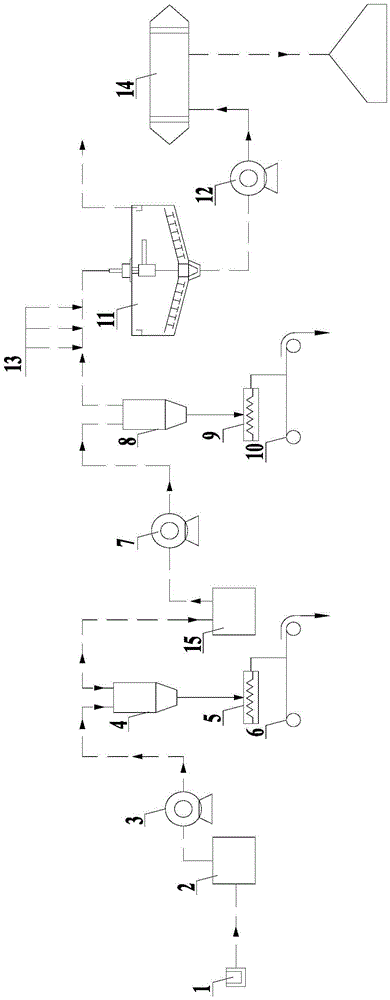

[0056] The treatment method of high-concentration suspended matter wastewater comprises the following steps:

[0057] 1) High-concentration suspended solids wastewater is discharged from the waste water collection channel 1 into the first sump 2, and then sent to the primary hydrocyclone 4 through the first water pump 3, and the high-concentration suspended solids wastewater is treated by the primary hydrocyclone 4 Finally, the sediment and overflow liquid are obtained, and the sediment obtained after being treated by the first-level hydrocyclone 4 is sent to the first strong dehydration equipment 5, and the first-level hydrocyclone 4 combined with the first strong dehydration equipment 5 can remove ≥0.038 mm particles can be reused as stone powder to reduce the load of waste residue treatment at the back end and protect equipment and filter cloth from wear and tear. The moisture content of stone powder dehydrated by the first powerful dehydration equipment 5 can be reduced to ...

Embodiment 2

[0064] The treatment method of high-concentration suspended matter wastewater is as in Example 1, wherein the flocculant is a mixture of PAM and CaO in a weight ratio of 1:15.

[0065] The sedimentation recovery rate of the secondary hydrocyclone reaches 47.8%, the particle settling speed of the radial flow sedimentation tank reaches 0.33mm / s, the solid content of the bottom sedimentation mud increases to 37%, the sedimentation and concentration effect is obvious, the effluent water quality is stable and meets the standard, and the high-efficiency diaphragm pressure The working cycle of the filter is stable at 45min to 50min, and the moisture content of the mud cake after pressing is 11%, which meets the conditions for cleaning and transportation, and greatly reduces the volume occupied by the mud cake.

Embodiment 3

[0067] The treatment method of high-concentration suspended matter wastewater is as in Example 1, wherein the flocculant is a mixture of PAM and CaO in a weight ratio of 1:60.

[0068] The sedimentation recovery rate of the secondary hydrocyclone reaches 46.4%, the particle settling speed of the radial flow sedimentation tank reaches 0.31mm / s, the solid content rate of the sedimentation mud at the bottom increases to 36%, the sedimentation and concentration effect is obvious, the effluent water quality is stable and meets the standard, and the high-efficiency diaphragm pressure The working cycle of the filter is stable at 45min to 50min, and the moisture content of the mud cake after pressing is 14%, which meets the conditions for cleaning and transportation, and greatly reduces the volume occupied by the mud cake.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com