chemical mechanical polisher

A chemical machinery and polishing machine technology, applied in the field of polishing machines, can solve the problems of gaps in the rotating structure, poor positioning accuracy of the polishing head, and large space occupied by the manipulator, so as to improve the installation stability, work reliability, and process improvement. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below, and examples of the embodiments are shown in the accompanying drawings. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention, but should not be construed as limiting the present invention.

[0028] The chemical mechanical polishing machine 100 according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

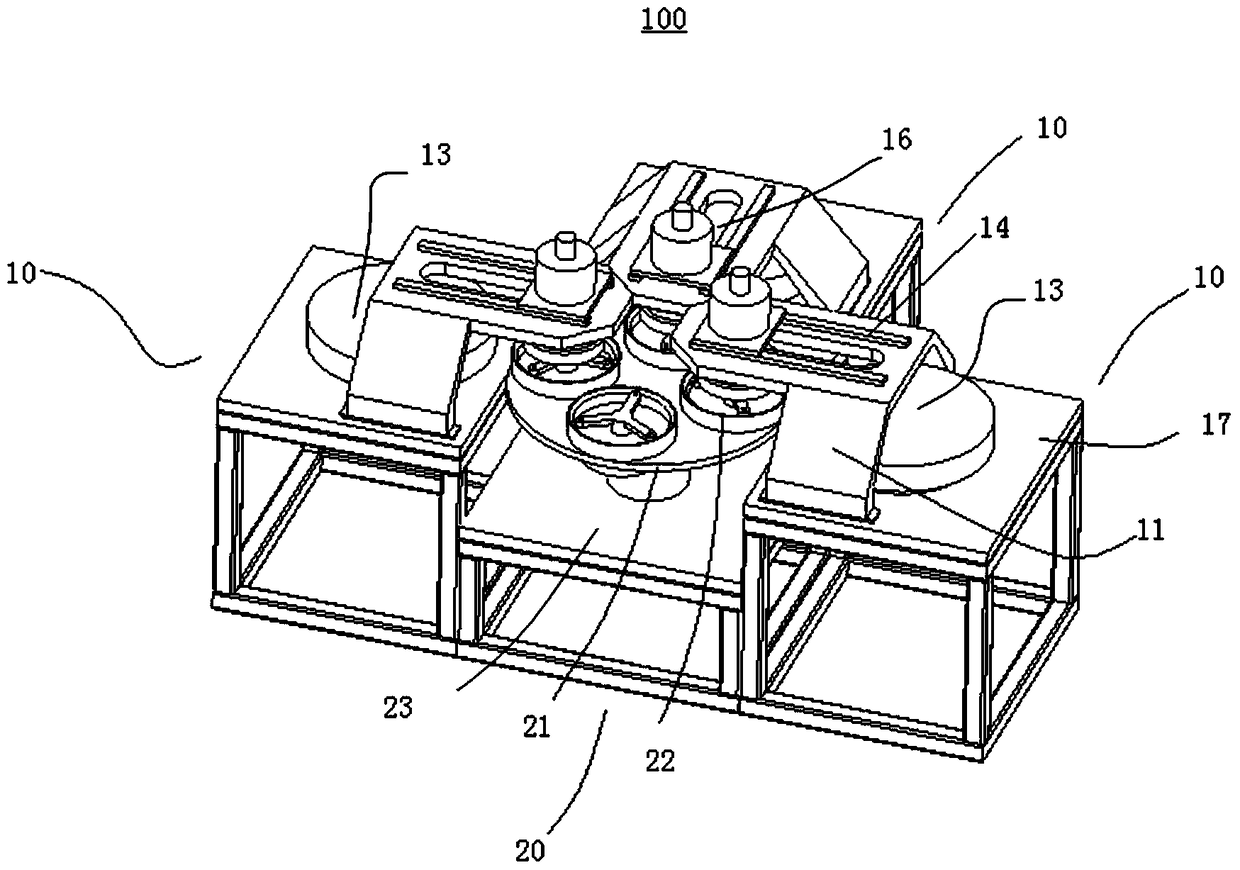

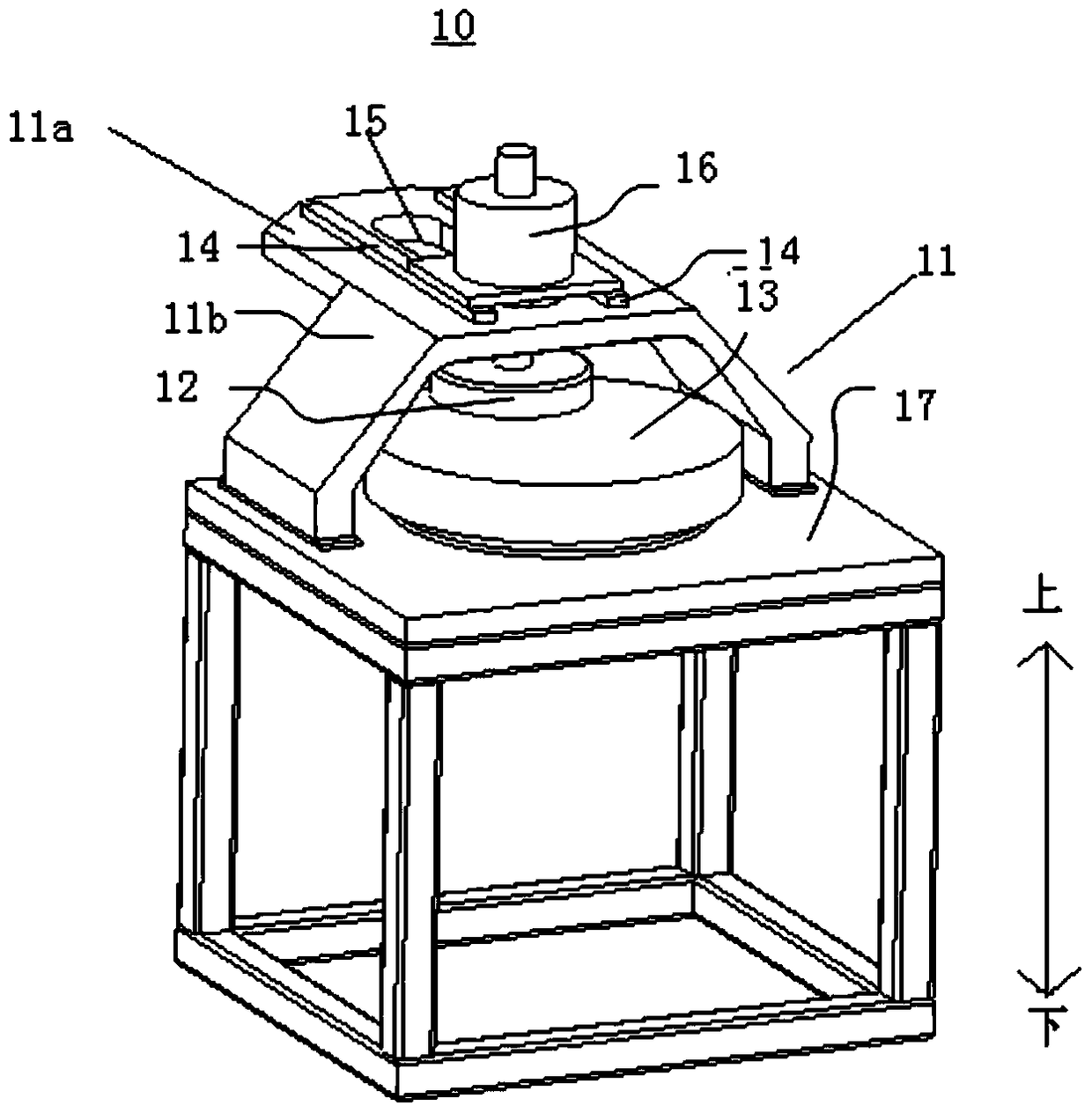

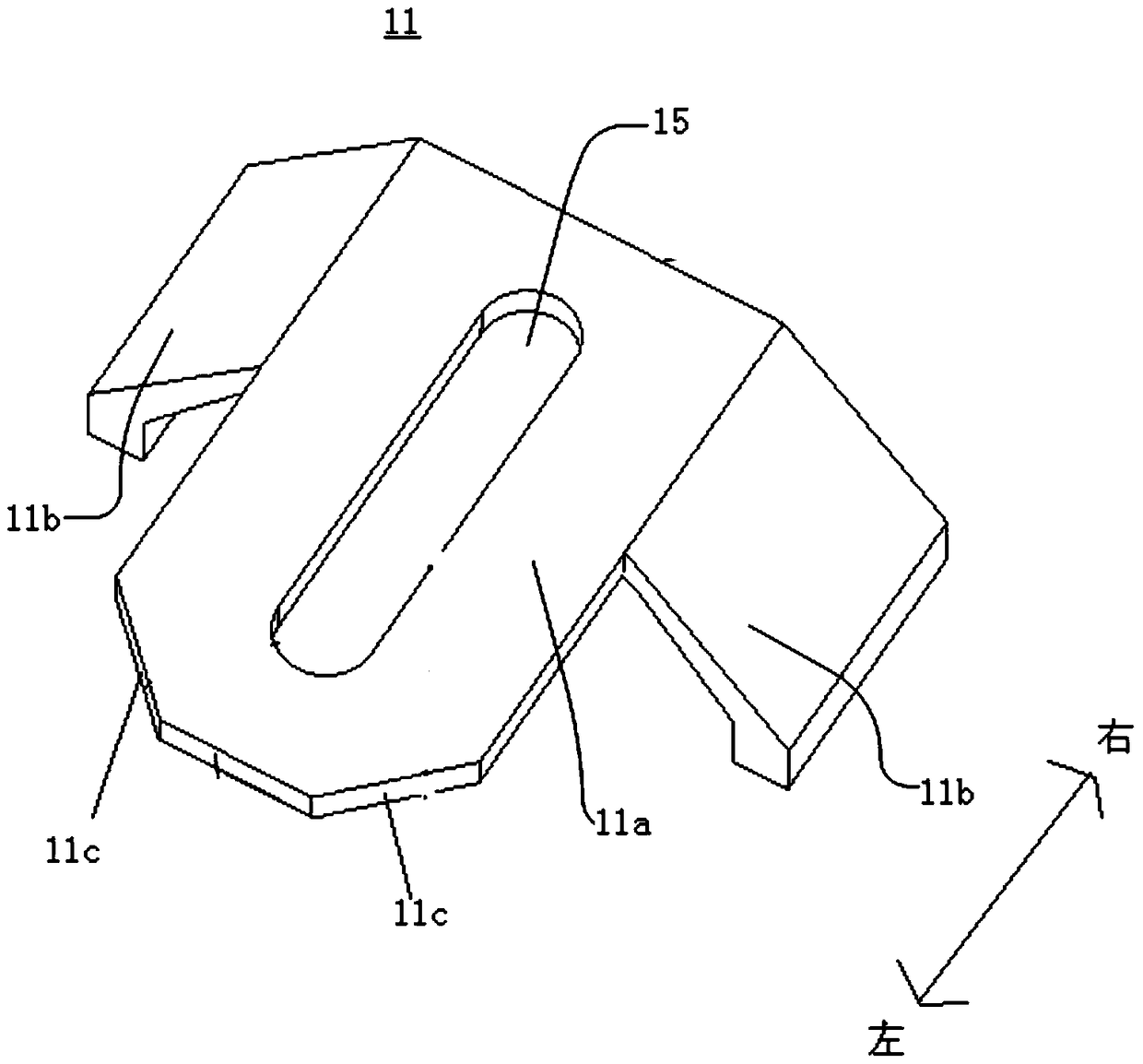

[0029] The chemical mechanical polishing machine 100 according to the embodiment of the present invention may include a plurality of polishing components 10 and a transmission component 20. A plurality of polishing components 10 can be arranged around the transmission component 20, such as figure 1 As shown, a plurality of polishing components 10 are arranged at intervals, and each polishing component 10 may include: a support 11, a polishing head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com