Bamboo-wood sawdust pet clustering padding material and preparation method thereof

A pet and bedding technology, which is applied in the field of excrement bedding and its preparation, can solve the problems of affecting the health of pets, being expensive, and increasing costs, and achieve the effects of protecting human and pet health, killing mold, and being easy to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

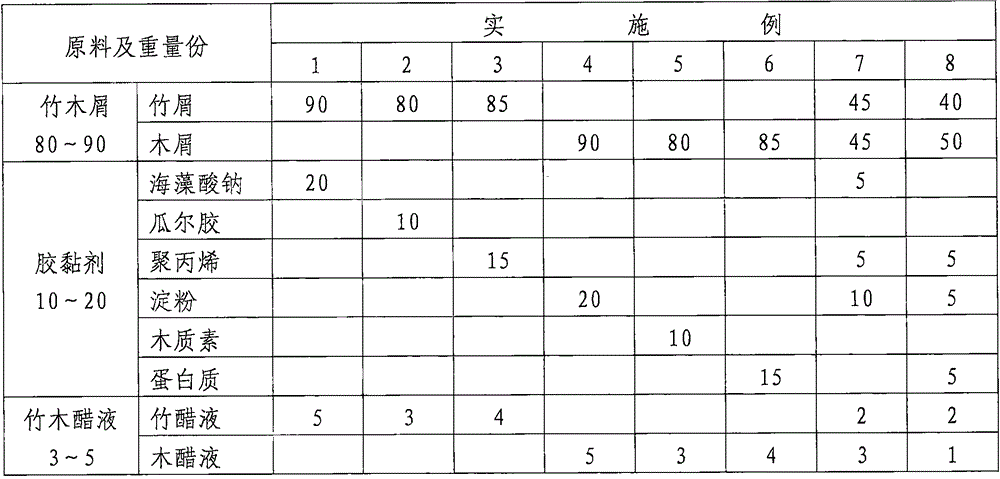

Embodiment 1

[0022] The specific preparation method of the bamboo sawdust pet agglomeration litter in this example is as follows: put 90 parts of bamboo chips in a pressure vessel and let it steam, treat it at 130°C for 3 hours, and then mix it with 20 parts of sodium alginate to Stir at a speed of 500r / min for 12min, then mix 5 parts of bamboo vinegar with water, adjust the moisture content of the mixture of bamboo chips and sodium alginate to 30%, and place it in the strip making machine to produce thin cylindrical strips after cooling. 22kg / min, ring die compression ratio 3, strip diameter 5mm, then dry the produced strip to a moisture content of 10%, place the strip in a roller cutter, cut into particles with a particle size of 5mm and vibrate Sieve the sieve, remove the particles with a particle size of <0.5mm, and inspect and pack the rest.

Embodiment 2

[0024] The specific preparation method of the bamboo sawdust pet agglomeration litter in this example is as follows: put 80 parts of bamboo chips in a pressure vessel and let it steam, treat it at 130°C for 3 hours, and then mix it with 10 parts of guar gum. Stir at a speed of 400r / min for 10 minutes, then mix 3 parts of bamboo vinegar with water, adjust the moisture content of the mixture of bamboo chips and guar gum to 30%, and place it in the strip making machine to produce thin cylindrical strips after cooling. 23kg / min, ring die compression ratio 5, strip diameter 5mm, then dry the produced strips to a moisture content of 8%, place the strips in a roller cutter, cut into particles with a particle size of 3mm and vibrate Sieve the sieve, remove the particles with a particle size of <0.5mm, and inspect and pack the rest.

Embodiment 3

[0026] The specific preparation method of the bamboo sawdust pet agglomeration litter in this example is as follows: put 85 parts of bamboo chips in a pressure vessel and pass through steam, treat at 130°C for 3 hours, then mix with 15 parts of polypropylene, and heat at 660r / min rotating speed stirs 15min, mixes with water again with 4 parts of bamboo vinegar liquids, adjusts the water content of the mixture of bamboo chips and polypropylene to 30%, puts in strip making machine after cooling and produces thin cylindrical strips Feeding speed 20kg / min, the compression ratio of the ring die is 6, the diameter of the strip is 5mm, and then the prepared strip is dried to a moisture content of 12%, and the strip is placed in a roller-type granulator, and the particles with a particle size of 8mm are cut into particles and vibrated and sieved Sieve, remove particles with a particle size of <0.5mm, and inspect and pack the rest.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com