High-multiplying power lithium ion battery and preparation method thereof

A lithium-ion battery and manufacturing method technology, applied in high-rate lithium-ion batteries, preparation of lithium-ion batteries, and manufacturing of high-rate lithium-ion batteries, can solve the problem of reducing lithium-ion transmission, unable to withstand high-current discharge, and reducing battery high-current Discharge performance and other issues, to achieve the effect of reducing current collector resistance, improving large current discharge capacity, and tight interface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

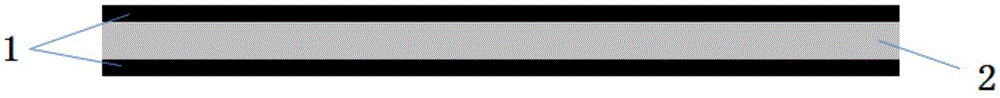

[0046] Add the weighed polyvinylidene fluoride and NMP (N,N-dimethylpyrrolidone) to the stirring tank in turn and stir for 2 hours under vacuum until the polyvinylidene fluoride is completely dissolved into a transparent solution with a concentration of 2%. Slowly add the weighed carbon fiber into the mixing tank, in which the mass ratio of polyvinylidene fluoride to carbon fiber is 1:1. After stirring for 4 hours, add the pore former ammonium carbonate of 5% by mass of the mixed slurry, and continue to stir for 2 hours to form Uniform and stable coating slurry. The coating slurry is uniformly coated on both sides of the diaphragm by gravure printing and dried to prepare a composite porous diaphragm with a single-sided coating thickness of 1 μm and a double-sided coating thickness of 2 μm. As attached figure 1 As shown, 1 is the composite coating and 2 is the diaphragm substrate.

[0047] LiCoO 2 As the positive active material of lithium ion battery, it is mixed with polyvinyli...

Embodiment 2

[0053] Add the weighed polyvinylidene fluoride and NMP (N,N-dimethylpyrrolidone) to a stirring tank in turn and stir for 2 hours under vacuum until the polyvinylidene fluoride is completely dissolved into a transparent solution with a concentration of 4%. Slowly add the weighed carbon nanotubes into the mixing tank, where the mass ratio of polyvinylidene fluoride to carbon fiber is 1:4. After stirring for 4 hours, add the pore former ammonium bicarbonate with 10% of the mixed slurry mass, continue Stir for 2 hours to form a uniform and stable coating slurry. The coating slurry is evenly coated on both sides of the diaphragm by transfer coating and dried to prepare a composite porous diaphragm. The single-sided coating thickness is 14μm and the double-sided coating is The thickness is 28 μm.

[0054] LiNi 0.5 Co 0.3 Mn 0.2 O 2 As the positive active material of lithium ion battery, it is mixed with polyvinylidene fluoride, Super-P, NMP, etc. to prepare LiNi 0.5 Co 0.3 Mn 0.2 O 2 T...

Embodiment 3

[0060] Add the weighed polyvinylidene fluoride and NMP (N,N-dimethylpyrrolidone) to the stirring tank in turn and stir for 2 hours under vacuum until the polyvinylidene fluoride is completely dissolved into a transparent solution with a concentration of 6%. Slowly add the weighed graphene into the mixing tank, where the mass ratio of polyvinylidene fluoride to carbon fiber is 1:9. After stirring for 4 hours, add the pore-forming agent ammonium bicarbonate with 20% of the mixed slurry mass, and continue stirring A uniform and stable coating slurry is formed in 2 hours. The coating slurry is uniformly coated on both sides of the diaphragm by high-speed spraying and dried to prepare a composite porous diaphragm. The thickness of the single-sided coating is 7μm and the thickness of the double-sided coating is 14μm. .

[0061] LiFePO 4 As the positive active material of lithium ion battery, it is mixed with polyvinylidene fluoride, Super-P, NMP, etc. to prepare LiFePO 4 The positive e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com