Microwave annealing device and method for repairing proton irradiation damage of inp-based hemt devices

A technology of microwave annealing and proton irradiation, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of affecting the DC and high-frequency characteristics of devices, deteriorating contact characteristics, and requiring high heat absorption of materials, etc. To achieve the effect of shortening heat conduction time, reducing heat loss, and good stability and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

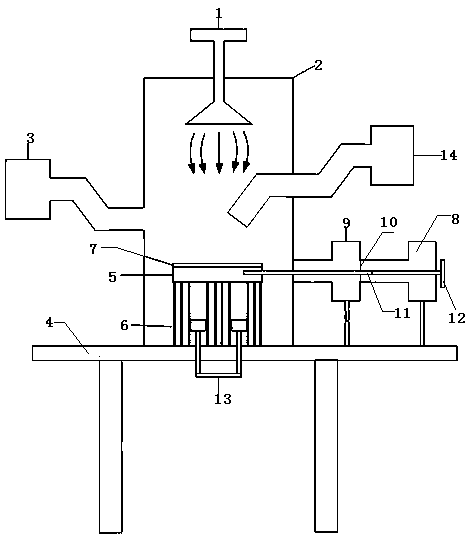

[0029] Such as figure 1 As shown, the present invention includes an operating table 4, a test chamber 2 located on the operating table 4, a sample base support 6 located in the test chamber 2 and on the table top of the operating table 4, and the sample base support 6 is a frame Body shape, the bottom of the frame body is fixed on the console 4 table tops, and the infrared thermometer 13 is arranged inside the frame body. The upper surface of the sample base 5 is provided with an electromagnetic wave auxiliary heating layer 7 . The sample delivery channel 8 connected to the test chamber 2, the telescopic transmission rod 11 arranged in the sample delivery channel 8, the vacuum pumping device 9, the inflation device 3, the microwave generator 1 and the infrared thermometer 13, the test chamber 2 It is sealed and connected with the operation table 4, the sample base 5 is placed on the sample base support 6, the sample conveying channel 8 is connected to the test chamber 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com