Polyethylene gas valve detection device

A testing equipment, polyethylene technology, applied in the direction of detecting the appearance of fluid at the leak point, measuring device, testing of mechanical parts, etc., can solve the problems of inability to gradually increase the torque, damage to the valve surface, low operating efficiency, etc. Improve the area utilization rate, high production efficiency, and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

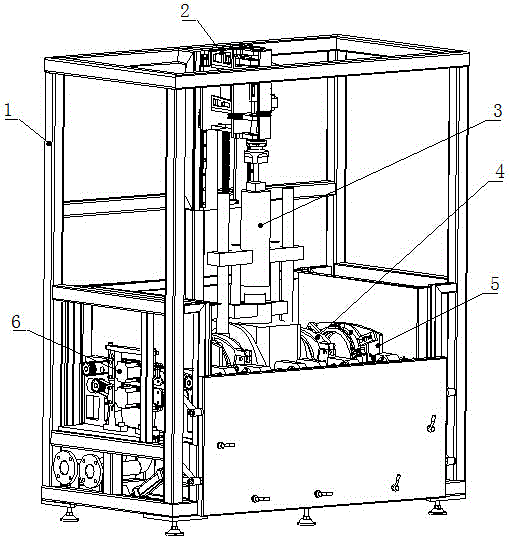

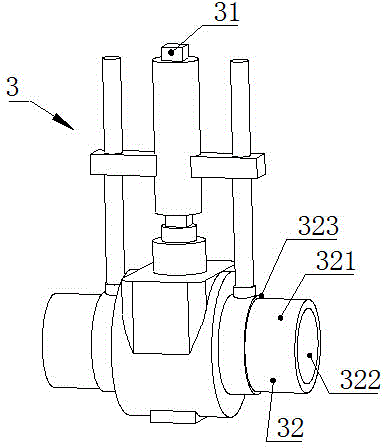

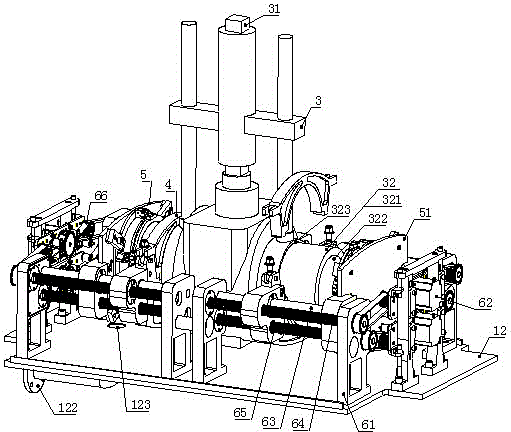

[0027] Such as figure 1 with figure 2 As shown, a polyethylene valve detection device is characterized in that it includes a frame assembly 1, a torque drive mechanism assembly 2, a valve limit mechanism assembly 4, a valve sealing mechanism assembly 5, and a limit mechanism assembly 4 and a sealing mechanism assembly 5 The mobile drive mechanism assembly 6 (the mobile drive assembly 6 will be briefly described below). The valve 3 to be tested is placed in the middle of the device, the handle 31 of the valve is vertically upward, and the torque drive mechanism assembly 2 is above the handle 31 of the valve. The pipes 32 on both sides of the valve are respectively provided with a set of valve limiting mechanism components 4 and valve sealing mechanism components 5 .

[0028] please watch carefully image 3 , The mobile drive mechanism assembly 6 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com