Regenerated stock solution colored high-speed polyester staple fiber sewing thread and preparation method thereof

A technology of polyester staple fiber and dope dyeing, applied in the direction of melt spinning, yarn, single-component polyester artificial filament, etc., can solve the problems of unenvironmental protection of the production process, increase of production links, waste of electricity and waste water, etc. Achieve the effect of optimizing the spinning process, reducing the production cost and reducing the yarn breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

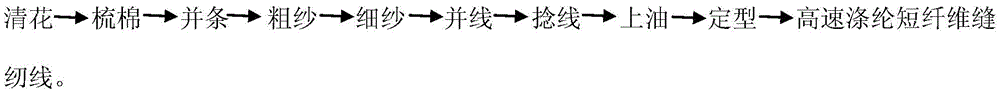

Method used

Image

Examples

Embodiment 1

[0032] A beige regenerated dope dyed high-speed polyester staple fiber sewing thread is prepared by the following method:

[0033] (1) After the recovered mineral water bottle is crushed, washed and dried, mineral water bottle fragments are obtained, and the beige color masterbatch after adding is mixed evenly, and then added into a screw extruder to be heated and melted into a melt; the dried The drying time is 10 to 12 hours, the drying temperature is ≤135°C, and the water content of the mineral water bottle fragments and the masterbatch is ≤120ppm after drying; the mass ratio of the mineral water bottle fragments to the masterbatch is 99:1;

[0034] (2) The melt is spun at a high speed through a filter, a metering pump, and a spinneret assembly to generate primary fibers; the specification of the filter is 200 mesh to 300 mesh; the spinneret assembly uses a filter screen of 200 mesh to 300 mesh , sea sand is assembled according to 3.0-4.0kg; the spinning temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com