Deep submersion pressure-resistant waterproof cable and preparation method thereof

A waterproof cable, pressure-resistant technology, used in cable/conductor manufacturing, submarine cables, insulated cables, etc., can solve problems such as easy breakage, and achieve the effect of avoiding conductor breakage, improving overall stability, and stable pitch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

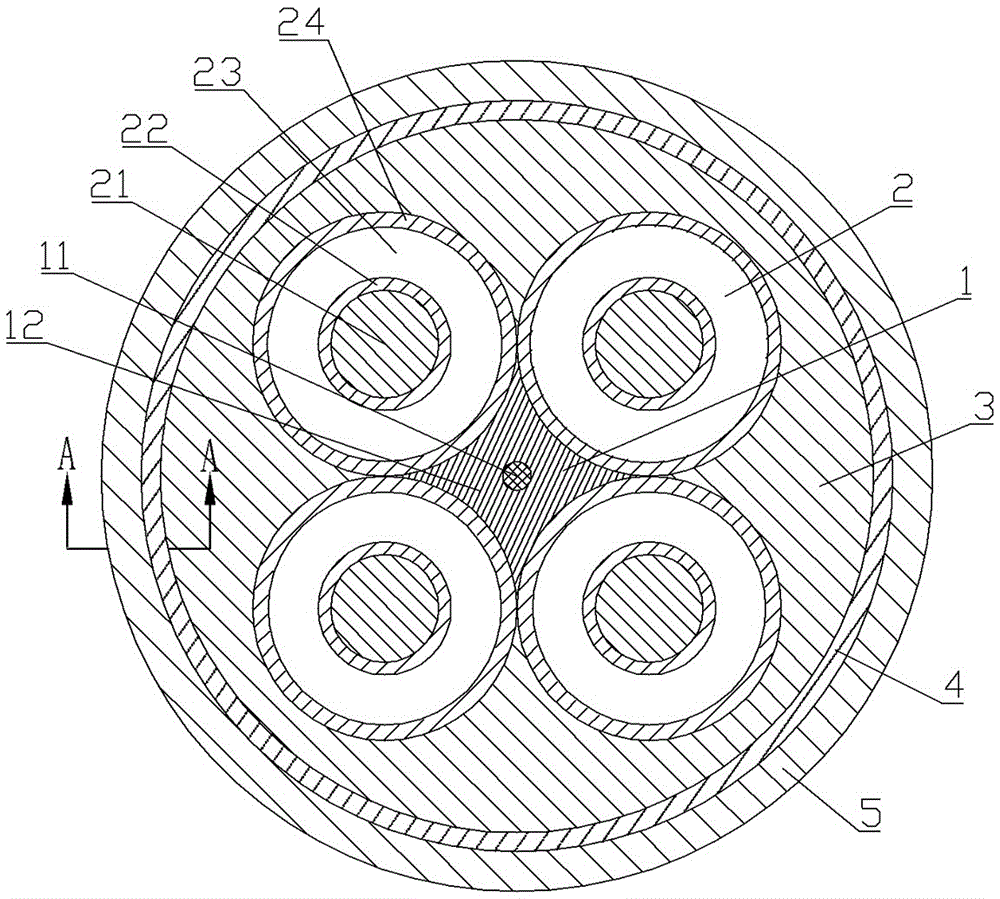

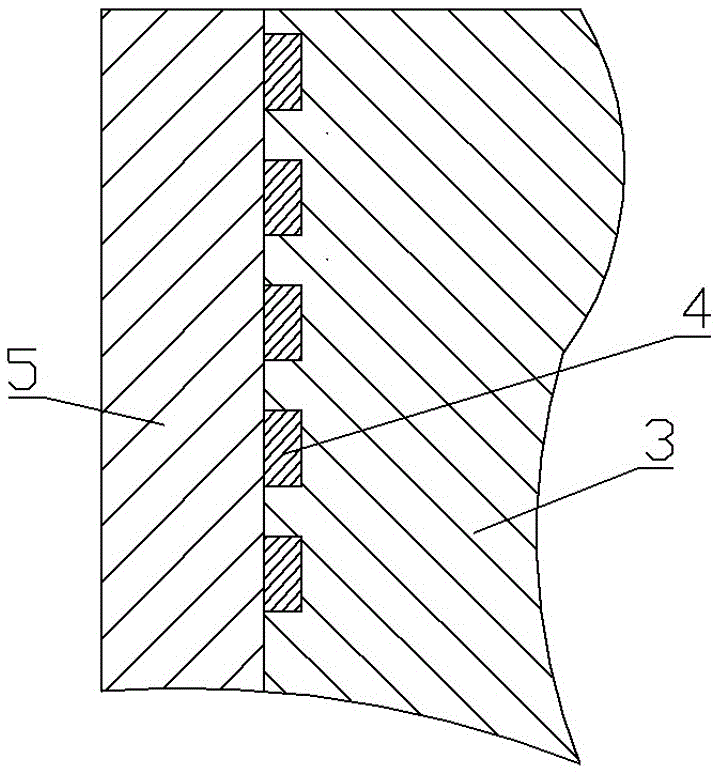

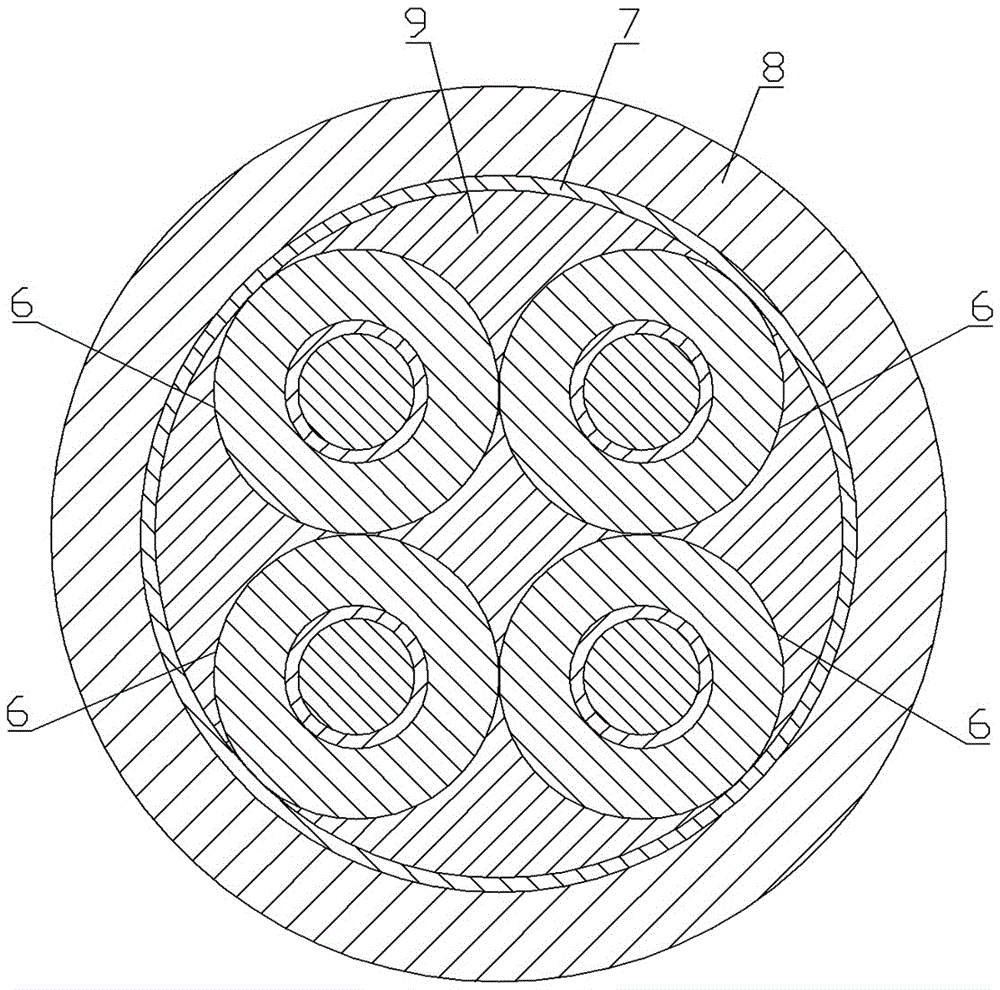

[0046] like figure 1 , 2 Shown: a deep-diving pressure-resistant and waterproof cable, including a flexible cable core 1, an insulated wire core 2, an inner sheath layer 3, a braided reinforcement layer 4 and an outer sheath layer 5. No less than four insulated wire cores 2 are evenly distributed around the flexible cable core 1, twisted into a strand to surround the flexible cable core 1; the inner sheath layer 3 is filled and adhered to the outside of the insulated wire core 2; braided reinforcement layer 4 gaps are wrapped around the outside of the inner sheath layer 3 , and the outer sheath layer 5 is overlapped and wrapped around the outside of the braided reinforcement layer 4 .

[0047] The flexible cable core 1 is composed of an aramid rope 11 and a flexible adhesive layer 12 extruded outside the aramid rope 11 . The flexible adhesive layer 72 is made of silicone rubber.

[0048] The insulated core 2 is composed of a conductor 21 , an inner insulating layer 22 wrap...

Embodiment 2

[0052] Compared with Example 1, this embodiment differs in that the material formulation of the inner sheath layer 3 and the outer sheath layer 5 is as follows: 100 parts of chlorinated polyethylene rubber, 15 parts of ethylene-butylene copolymer, ethylene-vinyl acetate 3 parts of grease rubber EVA, 10 parts of magnesium oxide, 3 parts of calcium zinc stabilizer, 2 parts of antiaging agent, 0.8 part of stearic acid, 9 parts of antimony trioxide, 2.5 parts of semi-refined paraffin, 22 parts of pigment carbon black, precipitation white 27 parts of carbon black, 50 parts of activated nano kaolin, 18 parts of flame retardant, 19 parts of talcum powder, 18 parts of dioctyl sebacate DOS, 6 parts of co-crosslinking agent, 5 parts of peroxide crosslinking agent.

[0053] The antiaging agent includes 1.0 parts of antiaging agent RD and 1.0 part of antiaging agent MB.

[0054] The beneficial effects brought by this formula are as follows: During the refining process, add chlorinated pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Constant | aaaaa | aaaaa |

| Constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com