Novel fiber high-voltage sensor

A high-pressure sensor, sensor technology, applied in instruments, fluid pressure measurement using optical methods, fluid pressure measurement, etc., can solve the problems of unavoidable noise interference and temperature drift, high maintenance costs, difficult deployment, etc., to achieve anti-electromagnetic The effect of strong interference, low processing cost and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

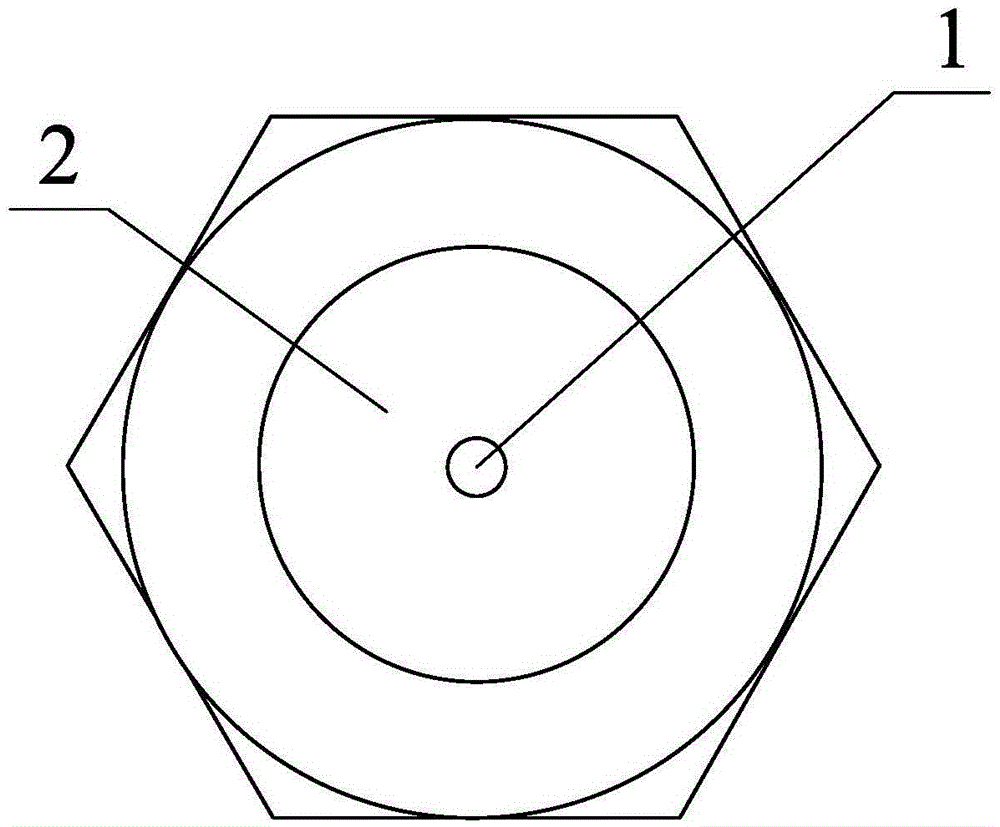

[0028] Such as figure 1 , 2 , 3, the novel optical fiber high pressure sensor of the present invention comprises a pressure inlet 1, a pressure source connector 2, a base 3, a casing 4, an optical cable waterproof connector 5, a sensing diaphragm 6, a multimode optical fiber 7, and an SMA metal optical fiber ferrule 8 , Armored fiber optic jacket 9.

[0029] The sides of the SMA metal optical fiber ferrule 8 and the base 3 are sealed by evenly applying epoxy resin, and the bottom surface is connected by laser welding; the sensing diaphragm 6 is a square diaphragm with a cylindrical Farper microcavity, and the SMA metal optical fiber ferrule The cores 8 are fixed by epoxy resin, and the signal quality is observed through the polarization low-coherence interference demodulation unit 18 before fixing to ensure the alignment of the diaphragm and the ferrule; the sides of the pressure source connector 2 and the base 3 are evenly coated with epoxy resin Sealed with glue, the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com