Wear and hydrolysis resistant PBT material, preparation method thereof, bowl blanket and dish washing machine

A hydrolysis-resistant and dishwasher-safe technology, which is applied in the field of bowl baskets and dishwashers, can solve the problems of large friction coefficient, poor hydrolysis resistance, and large friction coefficient of PBT materials, and achieve small surface friction coefficient, stable performance, and low wear resistance. The effect of a small coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] On the other hand, the embodiment of the present invention also provides a preparation method of the wear-resistant and hydrolysis-resistant PBT material of the above-mentioned embodiment of the invention. The preparation method of the wear-resistant and hydrolysis-resistant PBT material comprises the following steps:

[0044] 1. Weigh each component raw material according to the components of the wear-resistant and hydrolysis-resistant PBT material of the embodiment of the present invention described above;

[0045] 2. adding the anti-hydrolysis agent, composite antioxidant and processing aid to the PBT resin weighed in step 1. and carrying out mixing treatment;

[0046] ③ adding the wear-resistant agent to step ② for mixing;

[0047] ④ Melt blending and extruding the mixed material processed in step ③.

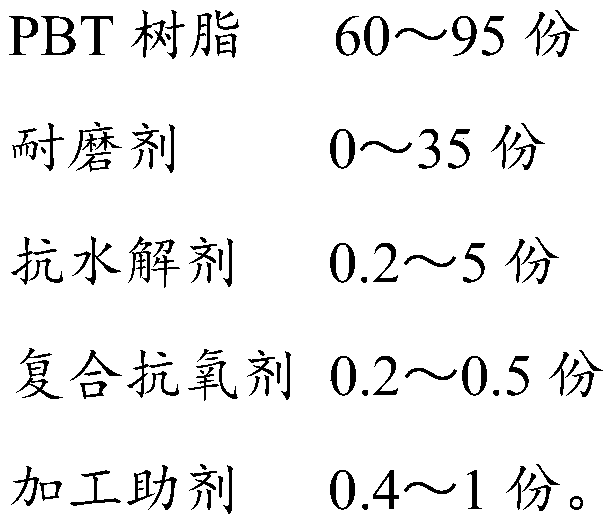

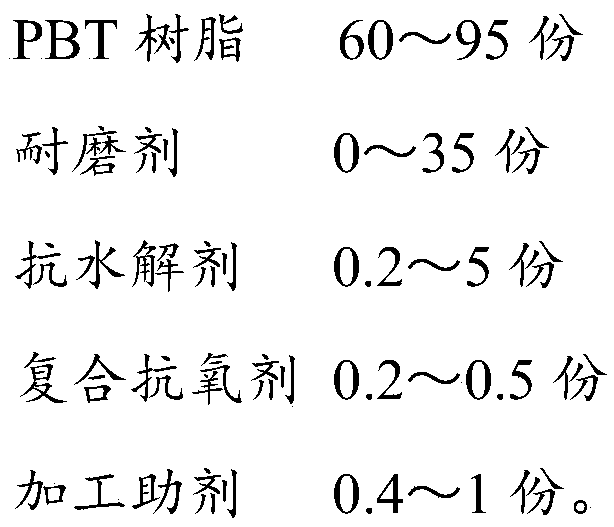

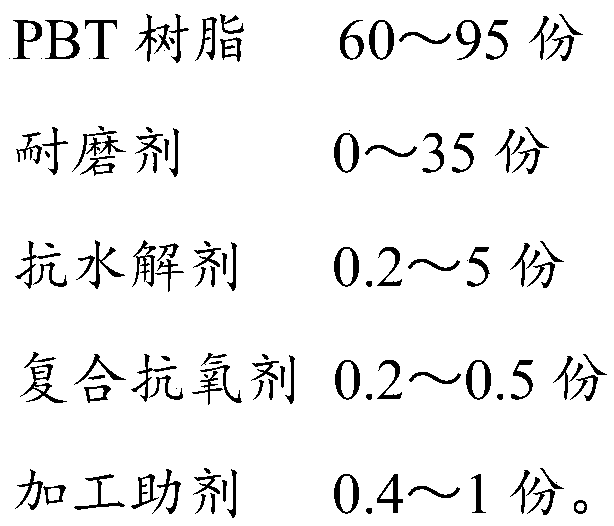

[0048] Specifically, the preferred content and types of the components of the wear-resistant and hydrolysis-resistant PBT material weighed in the above step ① are a...

Embodiment 1

[0059] A wear-resistant and hydrolysis-resistant PBT material and a preparation method thereof. The mass components contained in the wear-resistant and hydrolysis-resistant PBT material in Example 1 are shown in Table 1 below.

[0060] Among them, the PBT resin is 1200-211M; the wear-resistant agent is UHMWPE, the anti-hydrolysis agent is carbodiimide, the composite antioxidant is a mixture of S9228 and H161 with a mass ratio of 1:1, and the processing aids are silicone oil and GMA adhesive. branches.

[0061] Table 1: Formula composition of wear-resistant and hydrolysis-resistant PBT materials

[0062]

[0063]

[0064] The wear-resistant and hydrolysis-resistant PBT material of this embodiment 1 is prepared according to the following method: 1. Weigh each component raw material according to the components of the wear-resistant and hydrolysis-resistant PBT material described in any one of claims 1-6;

[0065] 2. adding the anti-hydrolysis agent, composite antioxidant ...

Embodiment 2

[0069] A wear-resistant and hydrolysis-resistant PBT material and a preparation method thereof. The mass components contained in the wear-resistant and hydrolysis-resistant PBT material in Example 1 are shown in Table 2 below. Among them, PBT resin is 1200-211M; wear-resistant agent is silicon nitride 2 The anti-hydrolysis agent is SAG copolymer, the composite antioxidant is a mixture of 1076 and 626 with a mass ratio of 1:2, and the processing aid is silicone oil and GMA graft. Its preparation method refers to the preparation method in Example 1.

[0070] Table 2: Formula composition of wear-resistant and hydrolysis-resistant PBT materials

[0071] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com