Ceramic fibrofelt air mixer

A technology of ceramic fiber mat and mixer, which is applied in mixers, dissolution, chemical instruments and methods, etc., can solve problems affecting product quality, fiber backflow blockage, and affecting mixing efficiency, so as to facilitate mixing efficiency and prevent fiber backflow blockage , Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

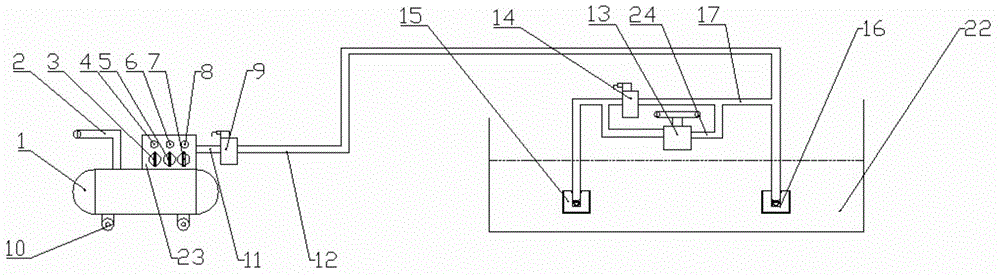

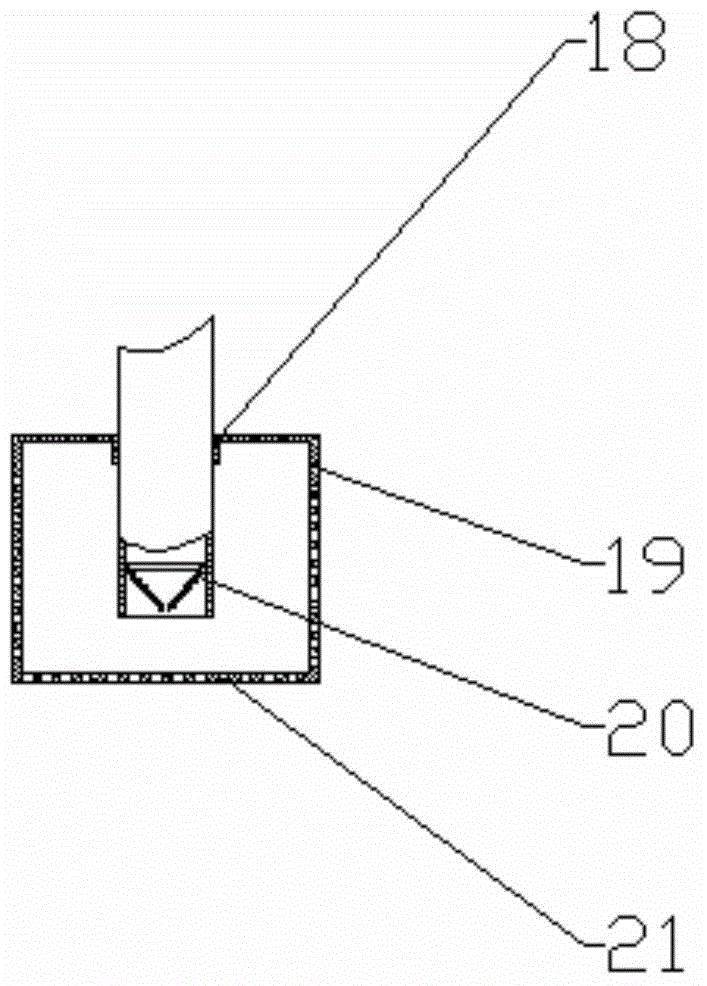

[0021] Such as figure 1 , figure 2 As shown, this embodiment includes an air compressor 1, the air compressor 1 is provided with a compressed air outlet 11, the compressed air outlet 11 is provided with an electromagnetic stop valve A9, the compressed air outlet 11 is connected to the compressed air inlet B16 through the air pipe A12, The air pipe A12 is connected to the compressed air inlet A15 through the air pipe B17. An electromagnetic cut-off valve B14 is installed between the air pipe B17 and the compressed air inlet A15. The air pipe B17 is connected in parallel with a manual cut-off valve 13 through the air pipe C24. Placed in the magma pool 22, the compressed air inlet A15 and the compressed air inlet B16 are provided with a filter cover 19, and a sealing ring 18 is arranged between the filter cover 19 and the compressed air inlet A15 and the compressed air inlet B16, and the filter cover 19 is provided with Several filter holes 21 are arranged, and anti-reflux rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com