Methylbenzene gas sensor based on alpha-Fe2O3/SnO2 heterostructure nanowire array and preparation method of methylbenzene gas sensor

A nanowire array and gas sensor technology, applied in the direction of material resistance, can solve the problem of high working temperature of gas sensitive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

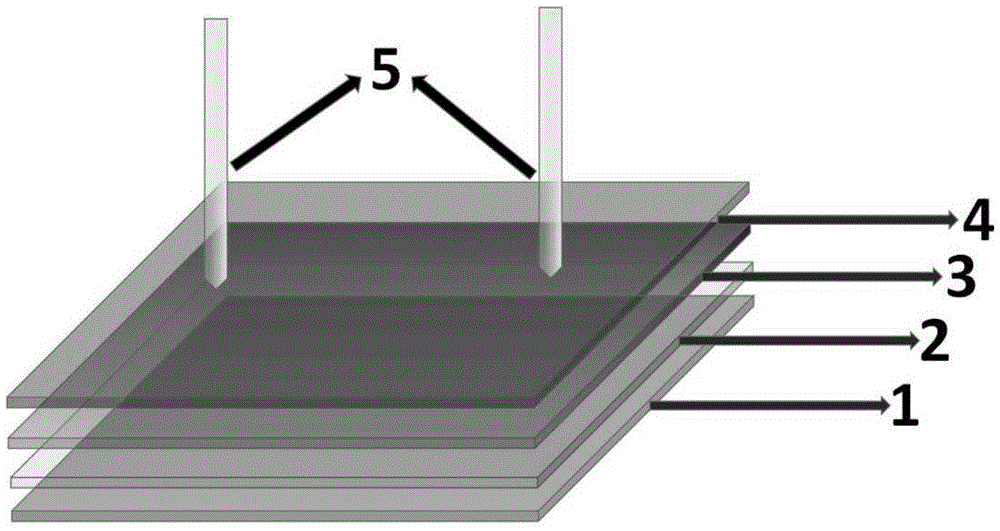

[0033] Preparation of SnO with Fe:Sn molar ratio of 1:125 2 Nanowire Arrays and α-Fe 2 o 3 The toluene gas sensor of nanorod composite N-N junction heterojunction structure nanomaterials, the specific manufacturing process is as follows:

[0034] 1. First, 1.75g of SnCl 4 ·5H 2 O. 100 μL of hydrochloric acid with a concentration of 0.2M was added to 15 mL of deionized water in turn, and stirred for 15 min until it was completely dissolved;

[0035] 2. Pour the solution of step 1 into an ultrasonic spray reaction container, and then place a Pt-coated silicon wafer (Pt-plated on a silicon wafer by vacuum evaporation technology) in a quartz tube. Using an ultrasonic atomization system, the solution in step 1 is dispersed into mist-like droplets of small molecules by ultrasonic waves, and then nitrogen is used as a carrier gas, and the atomized small molecules are brought into the quartz tube of the high-temperature reaction furnace by the carrier gas, at 350 Ultrasonic spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com