Acicular ferritic steel for low-manganese high-chromium anti-hic pipeline and manufacturing method thereof

A technology for ferritic steel and a manufacturing method, applied in the field of ferritic steel, can solve the problems of not significantly increasing the cost, and achieve the effects of reduced steelmaking process requirements, good matching of strength and toughness, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

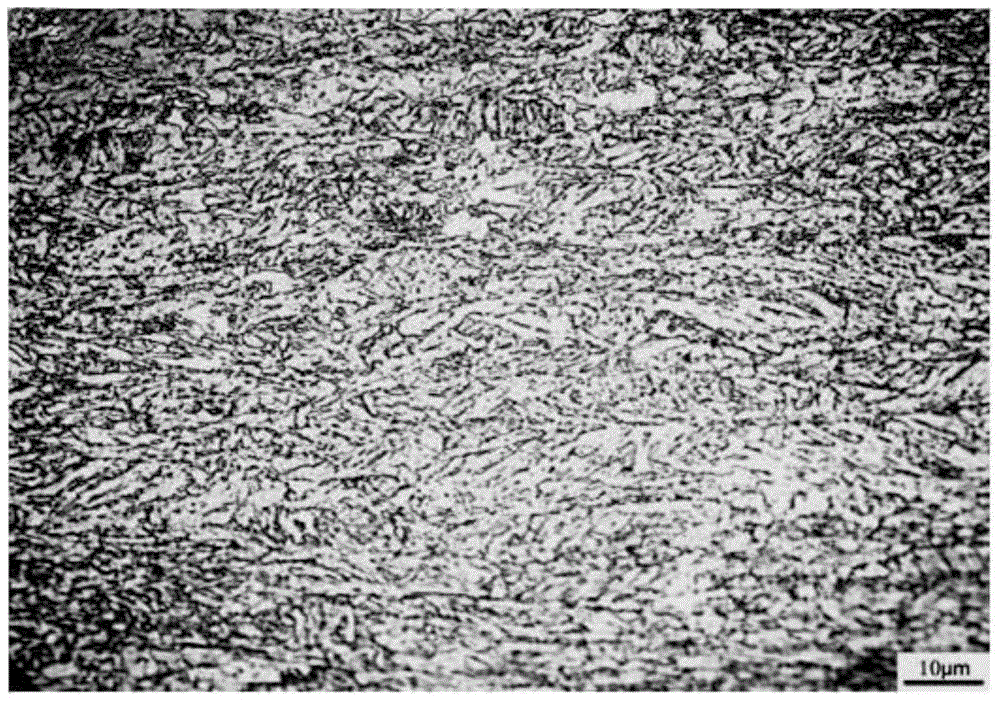

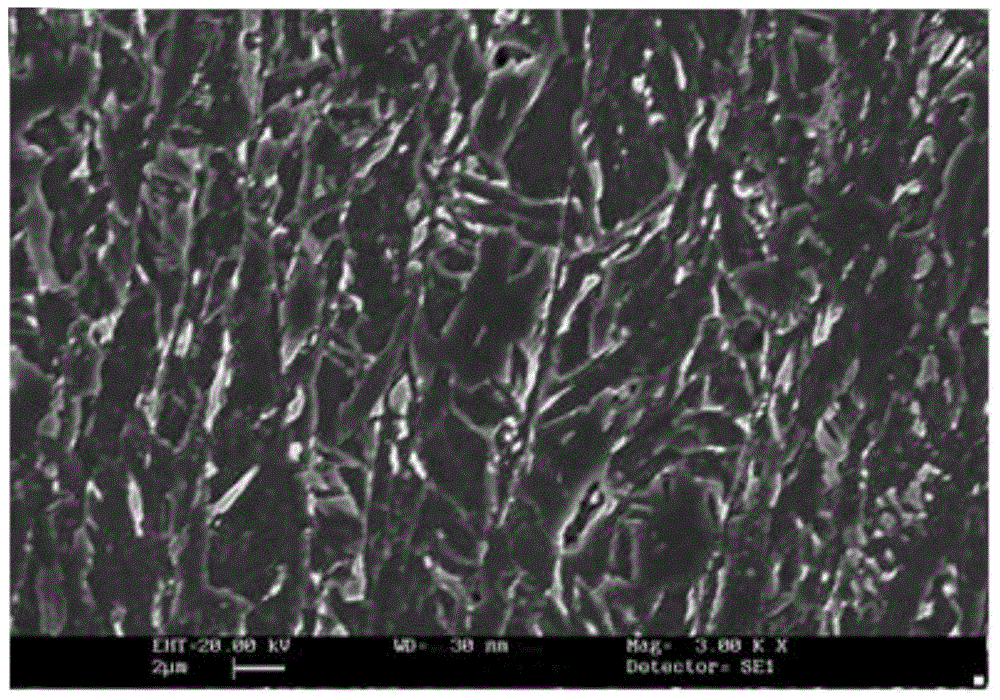

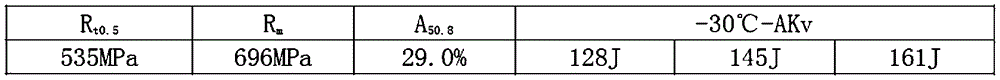

Embodiment 1

[0025] According to the chemical composition range requirements of acicular ferritic steel for low manganese and high chromium anti-HIC pipelines, molten steel smelting, billet casting and steel plate rolling are completed; billet size: 300mm thick*1620mm wide*3000mm long steel plate size: 19.3mm Thickness*1848mm width*12050mm length, 3 fixed lengths. The chemical composition percentages are shown in Table 1:

[0026] Table 1 embodiment actual chemical composition (%)

[0027] C Si mn Cr Nb Ti P S Alt N Ca 0.038 0.33 0.35 0.85 0.06 0.016 0.011 0.0067 0.034 0.0055 0.0030

[0028] 1. The reference liquidus temperature is 1521°C: converter tapping is 1655°C; LF end is 1638°C; RH end is 1589°C; soft blowing end temperature is 1562°C; tundish temperature is 1538°C.

[0029] 2. Continuous casting process of 300mm thick continuous casting slab: casting speed: 0.78m / min, low magnification central segregation of slab C class 0.5.

[0030] 3...

Embodiment HI

[0034] Table 3 Example HIC performance (%)

[0035] Section number CLR CTR CSR 1 6.13% 5.31% 0.325% 2 0 0 0 3 0 0 0 average value 2.04% 1.77% 0.108%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com