A kind of yield strength 960mpa automobile frame steel and its production method

The invention relates to a technology for automobile beam steel and a production method, which is applied in the field of automobile beam steel with a yield strength of 960 MPa and its production field. The effect of good low temperature impact toughness and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

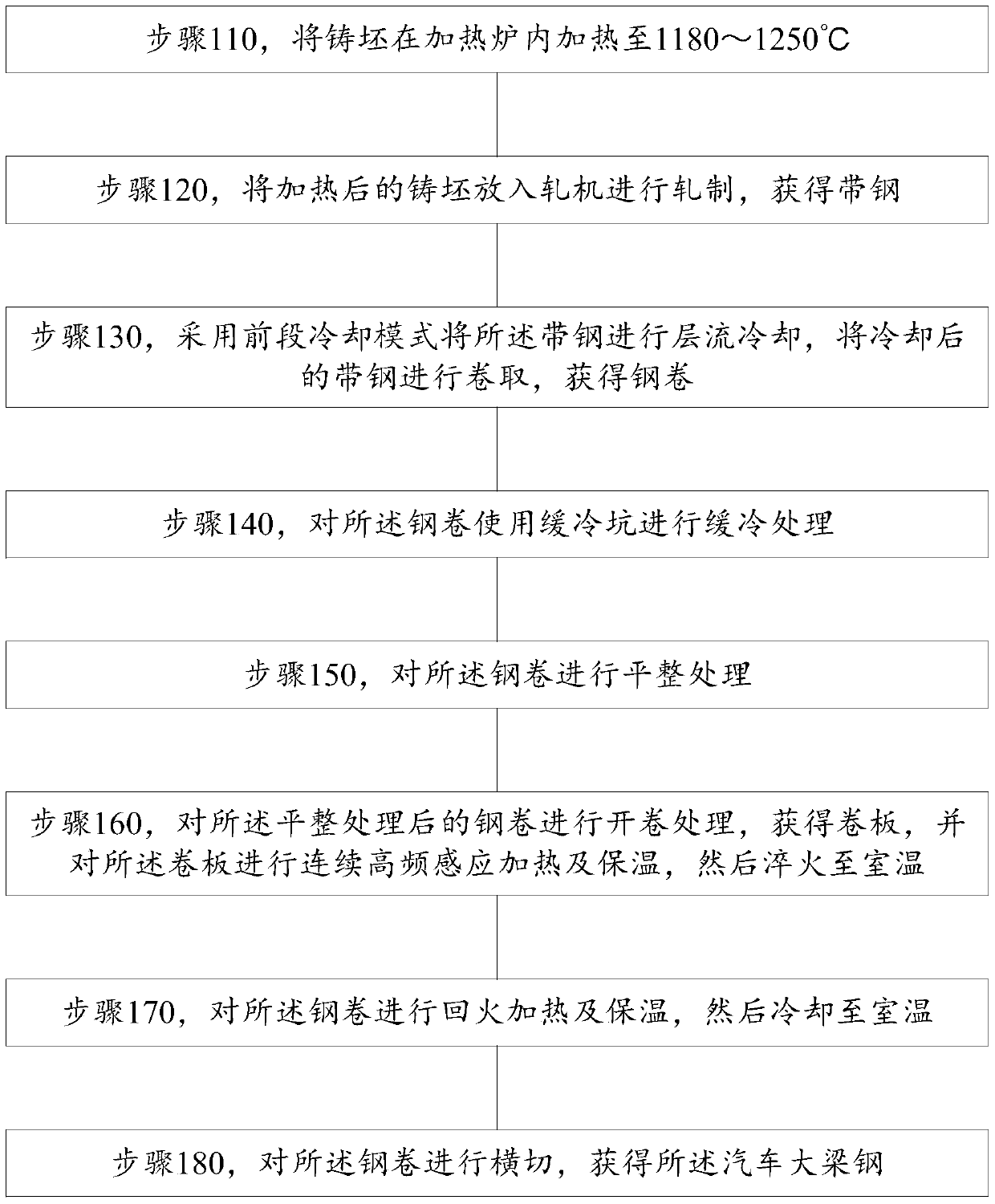

Method used

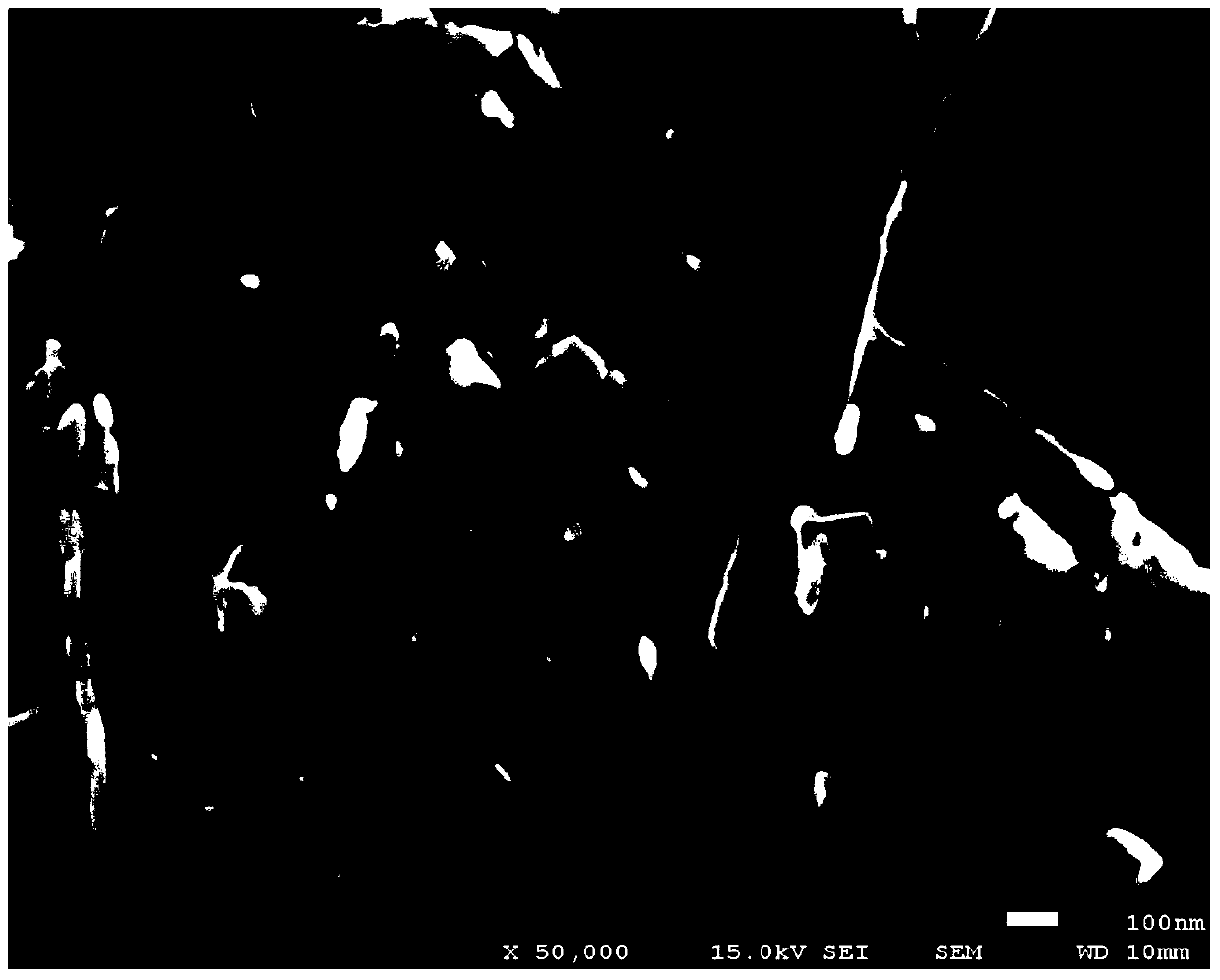

Image

Examples

example 1

[0074] Example 1 is smelted in a 220-ton converter and rolled on a 2250 hot rolling production line. The target width of the finished steel plate is 1500mm and the thickness is 3mm. The specific steps of smelting are:

[0075] S1: Slabs are obtained after molten steel is smelted in a converter; the content of P and S is strictly controlled during the smelting process to ensure the quality of the slabs. The chemical composition of the slab is as follows: calculated by mass percentage, C: 0.14%, Si: 0.20%, Mn: 1.20%, P: 0.014%, S: 0.003%, Al: 0.035%, Nb: 0.02%, Cr: 0.40 %, Mo: 0.30%, V: 0.08%, Ti: 0.025%, B: 0.0015%, N: 0.003%, and the balance is Fe and unavoidable impurities.

[0076] S2: Put the billet into the heating furnace for heating, the heating temperature is controlled at 1250° C., and the holding time is controlled at 215 minutes.

[0077] S3: putting the heated billet into a rolling mill for rolling to obtain a hot-rolled plate. Wherein, the entrance temperature in...

example 2

[0086] Example 2 is smelted in a 220-ton converter and rolled on a 2250 hot rolling production line. The target width of the finished steel plate is 1500mm and the thickness is 4mm. The specific steps of smelting are:

[0087] S1: Slabs are obtained after molten steel is smelted in a converter; the content of P and S is strictly controlled during the smelting process to ensure the quality of the slabs. The chemical composition of the slab is as follows: calculated by mass percentage, C: 0.13%, Si: 0.22%, Mn: 1.30%, P: 0.012%, S: 0.002%, Al: 0.040%, Nb: 0.03%, Cr: 0.45 %, Mo: 0.35%, V: 0.10%, Ti: 0.035%, B: 0.0016%, N: 0.002%, and the balance is Fe and unavoidable impurities.

[0088] S2: Put the billet into the heating furnace for heating, the heating temperature is controlled at 1250° C., and the holding time is controlled at 220 minutes.

[0089] S3: putting the heated billet into a rolling mill for rolling to obtain a hot-rolled plate. Wherein, the entrance temperature in...

example 3

[0098] Example 3 A 220-ton converter is used for smelting, and a 2250 hot rolling production line is used for rolling. The target width of the finished steel plate is 1500mm, and the thickness is 5mm. The specific steps of smelting are as follows:

[0099] S1: Slabs are obtained after molten steel is smelted in a converter; the content of P and S is strictly controlled during the smelting process to ensure the quality of the slabs. The chemical composition of the slab is as follows: calculated by mass percentage, C: 0.13%, Si: 0.25%, Mn: 1.50%, P: 0.011%, S: 0.003%, Al: 0.036%, Nb: 0.025%, Cr: 0.50 %, Mo: 0.40%, V: 0.12%, Ti: 0.025%, B: 0.0018%, N: 0.003%, and the balance is Fe and unavoidable impurities.

[0100] S2: put the billet into the heating furnace for heating, the heating temperature is controlled at 1240° C., and the holding time is controlled at 220 minutes.

[0101] S3: putting the heated billet into a rolling mill for rolling to obtain a hot-rolled plate. Among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com