Technology for smelting and casting C18150 alloy under atmosphere condition

A technology of alloy process and atmospheric conditions, which is applied in the field of smelting and casting C18150 alloy process under atmospheric conditions, can solve the problems of unstable chemical composition content, large investment, uneven distribution and other problems of non-vacuum method, so as to reduce raw material consumption and metal loss , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

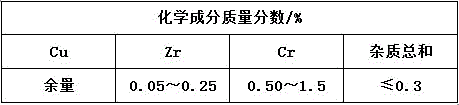

[0046] Adopt the present invention to produce C18150 (chromium zirconium copper alloy) ∮ 223mm round ingot.

[0047] Require.

[0048] The newly built furnace is over-produced for no less than 3 days in the early stage, and then goes to produce chrome-zirconium-copper alloy.

[0049] The crystallizer is circular, with a diameter of ∮227mm, and the dummy head extends into 1 / 3 of the mold from the direction of the ingot exit.

[0050] Chromium zirconium copper alloy operation process.

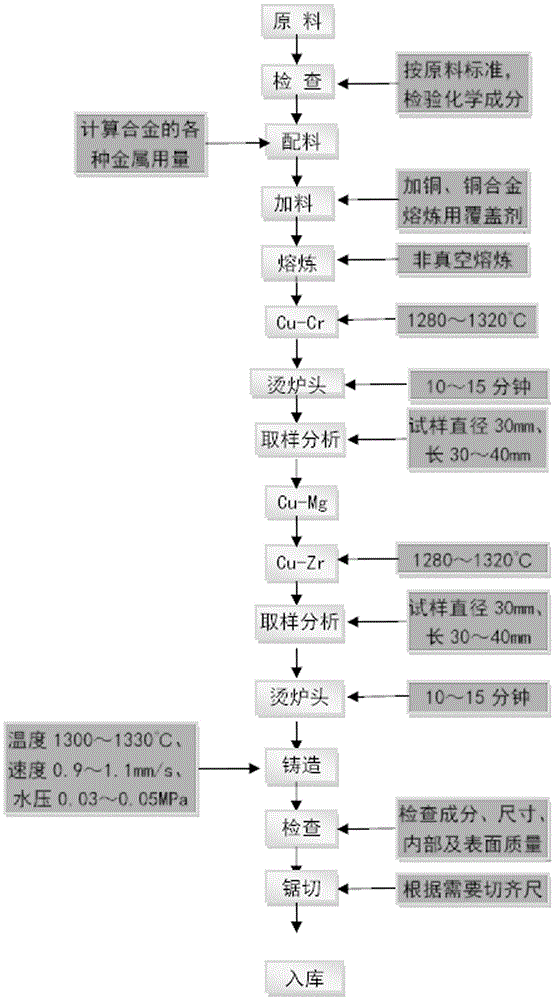

[0051] Ingredients—furnace loading—adding covering agent for copper alloy smelting—melting—adding copper-chromium master alloy—heating and melting—scalding burner head—sampling analysis—adding copper-magnesium master alloy for deoxidation—adding copper-zirconium master alloy—standstill—sampling analysis, Adjust the composition - hot burner head - casting.

[0052] Process control conditions.

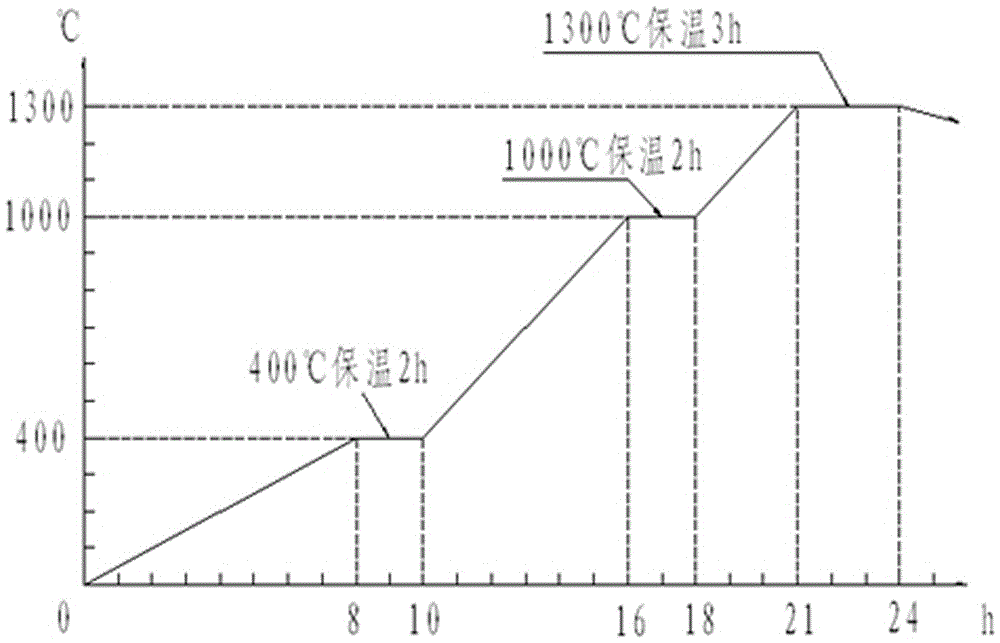

[0053] a. Baking covering agent.

[0054] Covering agent for copper alloy smelting, fully dried bef...

Embodiment 2

[0068] Adopt the present invention to produce ∮253mm round ingot.

[0069] Require.

[0070] The newly built furnace is over-produced for no less than 3 days in the early stage, and then goes to produce chrome-zirconium-copper alloy.

[0071] The crystallizer is circular, with a diameter of ∮258mm, and the dummy head extends into 1 / 3 of the mold from the direction of the ingot exit.

[0072] Chromium zirconium copper alloy operation process.

[0073] Ingredients—furnace loading—adding covering agent for copper alloy smelting—melting—adding copper-chromium master alloy—heating and melting—scalding burner head—sampling analysis—adding copper-magnesium master alloy for deoxidation—adding copper-zirconium master alloy—standstill—sampling analysis, Adjust the composition - hot burner head - casting.

[0074] process control.

[0075] a. Baking covering agent.

[0076] Covering agent for copper alloy smelting, fully dried before use, the process is 500 ℃ / 5-6 hours, after dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com