TiO2-reduced graphene composite and preparation method thereof and application of TiO2-reduced graphene composite to artificial sea water system

A composite material, graphene technology, applied in seawater treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of surface active site occupation, catalytic activity reduction, disappearance, etc., to improve degradation activity, simple preparation method, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Catalyst preparation

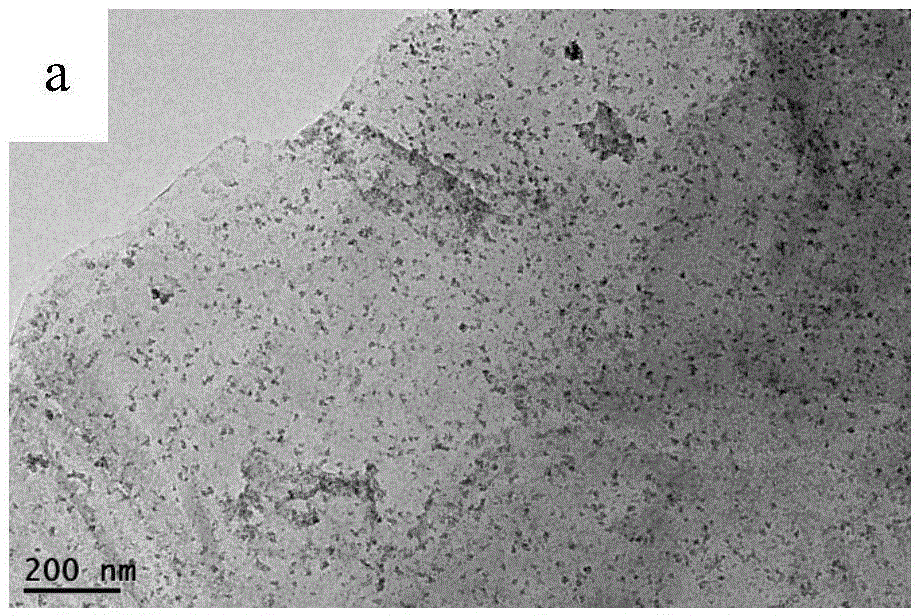

[0046] Get 0.5g graphene oxide with hydrophilic surface (specific surface area 50m 2 / g), 200mL of absolute ethanol and 1.5mL of deionized water were placed in a flask, stirred and adsorbed in a water bath at 30°C. After adsorption equilibrium (more than 12 hours), a stable adsorption water layer is formed on the surface of graphene oxide.

[0047] Another 50 mL of absolute ethanol in which 2.15 g of tetrabutyl titanate was dissolved was dropped into the adsorption equilibrium system drop by drop using a constant pressure funnel. Tetrabutyl titanate will diffuse into the adsorbed water layer, and form TiO in the adsorbed layer on the surface of graphene oxide through hydrolysis and polycondensation reactions. 2 Nanoparticles. After the reaction was completed (5 hours), the obtained 2 - Suspension system of graphene oxide particles.

[0048] The post-reaction suspension system was added to a high-pressure reactor lined with polytetrafluoro...

Embodiment 2

[0058] (1) Catalyst preparation

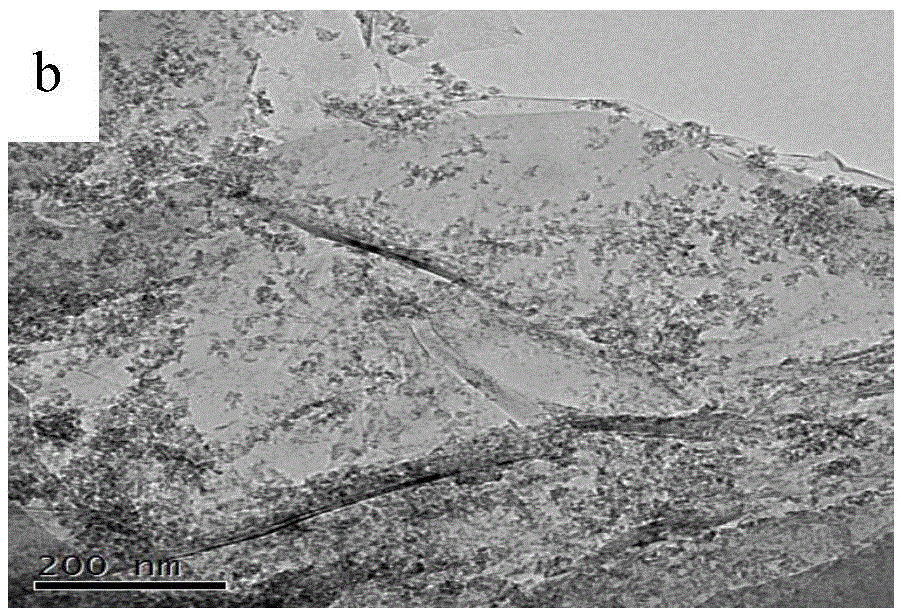

[0059] Get 0.6g graphene oxide (specific surface area 50m 2 / g), 200mL of absolute ethanol and 1.5mL of deionized water were placed in a flask, stirred and adsorbed in a water bath at 30°C. After adsorption equilibrium (more than 12 hours), a stable adsorption water layer is formed on the surface of graphene oxide.

[0060] Another 50 mL of absolute ethanol in which 2.15 g of tetrabutyl titanate was dissolved was dropped into the adsorption equilibrium system drop by drop using a constant pressure funnel. Tetrabutyl titanate will diffuse into the adsorbed water layer, and form TiO in the adsorbed layer on the surface of graphene oxide through hydrolysis and polycondensation reactions. 2 Nanoparticles. After the reaction was completed (5 hours), the obtained 2 - Suspension system of graphene oxide particles.

[0061] The post-reaction suspension system was added to a high-pressure reactor lined with polytetrafluoroethylene, sealed and plac...

Embodiment 3

[0071] (1) Catalyst preparation

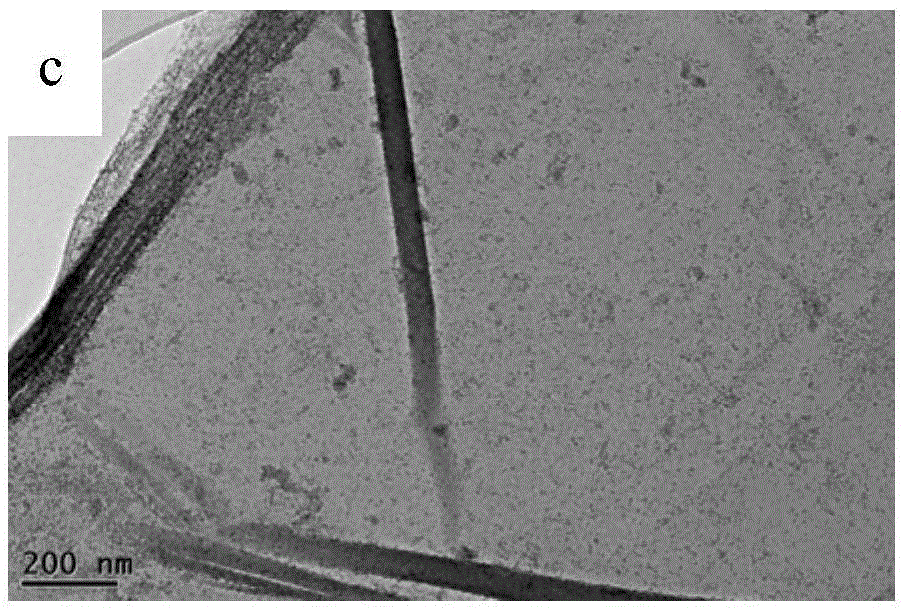

[0072] Get 0.8g graphene oxide (specific surface area 100m 2 / g), 200mL of absolute ethanol and 3.0mL of deionized water were placed in a flask, stirred and adsorbed in a 30°C water bath. After adsorption equilibrium (more than 12 hours), a stable adsorption water layer is formed on the surface of graphene oxide.

[0073] Another 50 mL of absolute ethanol in which 2.15 g of tetrabutyl titanate was dissolved was dropped into the adsorption equilibrium system drop by drop using a constant pressure funnel. Tetrabutyl titanate will diffuse into the adsorbed water layer, and form TiO in the adsorbed layer on the surface of graphene oxide through hydrolysis and polycondensation reactions. 2 Nanoparticles. After the reaction was completed (5 hours), the obtained 2 - Suspension system of graphene oxide particles.

[0074] The post-reaction suspension system was added to a high-pressure reactor lined with polytetrafluoroethylene, sealed and placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com