A constant force grinding tool for grinding the mold surface of an automobile panel

A technology for automobile cover parts and mold profiles, which is applied to grinding tools, grinding devices, grinding machine tools, etc., can solve the problems of increasing the mold manufacturing cycle, reducing the mold manufacturing efficiency, and long grinding time, shortening the manufacturing cycle and saving manpower. , the effect of high grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

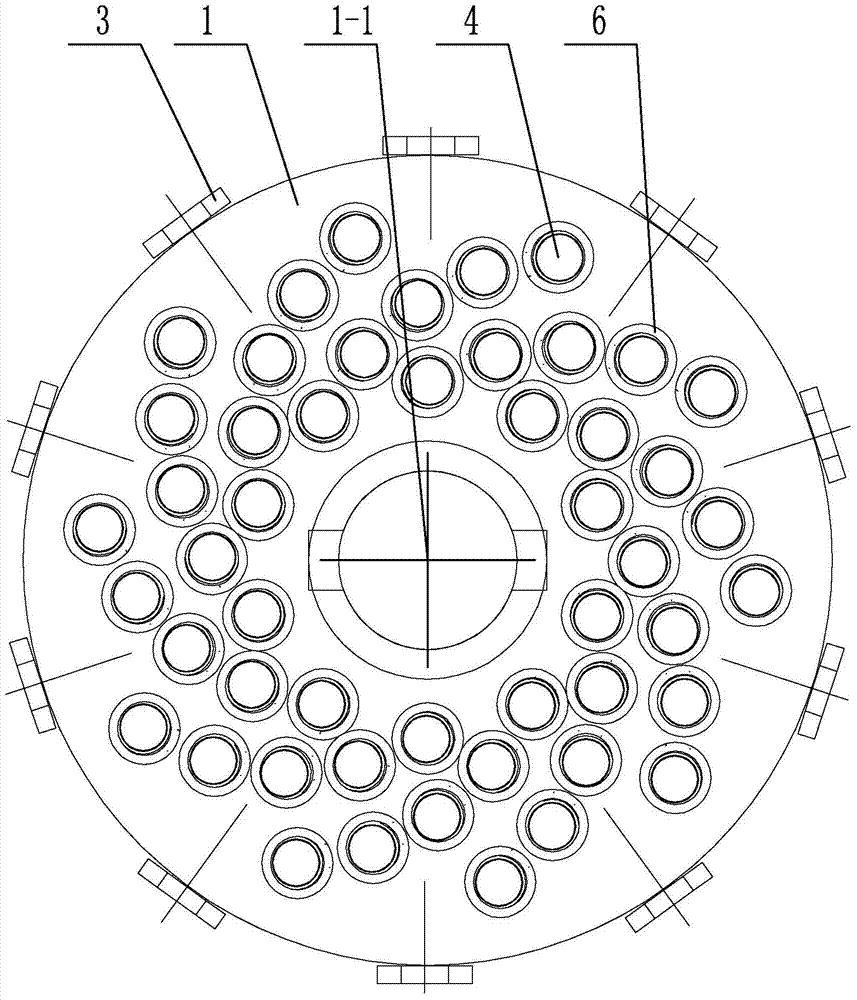

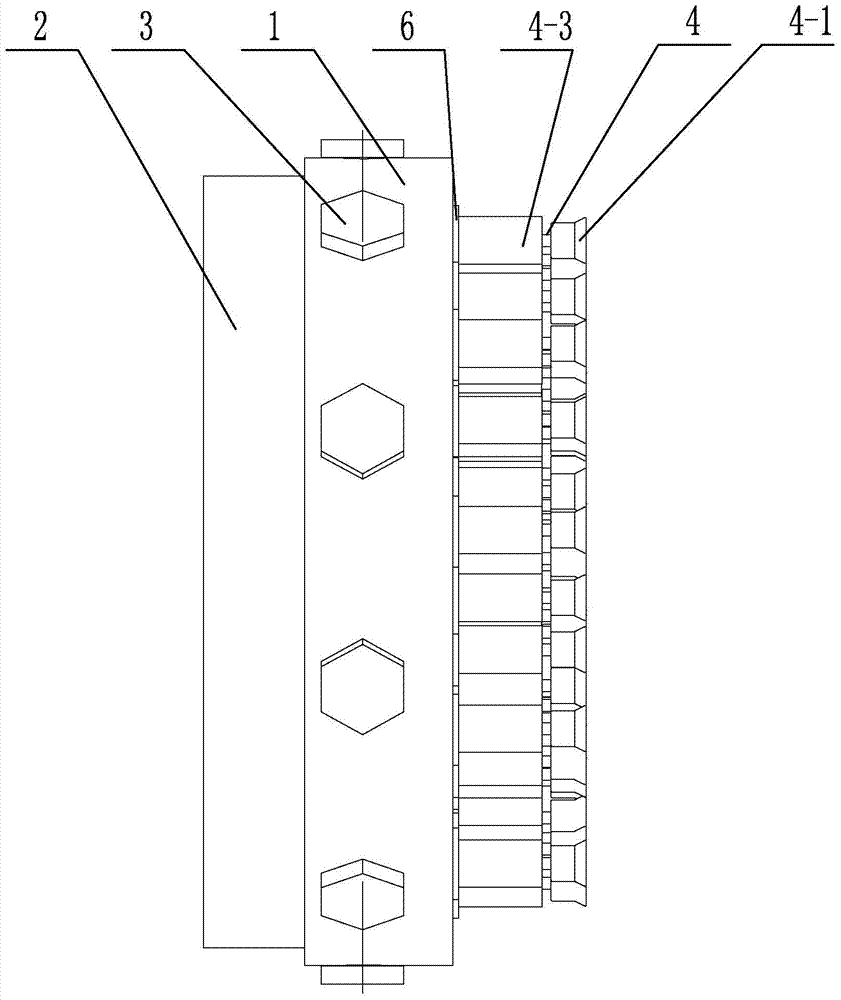

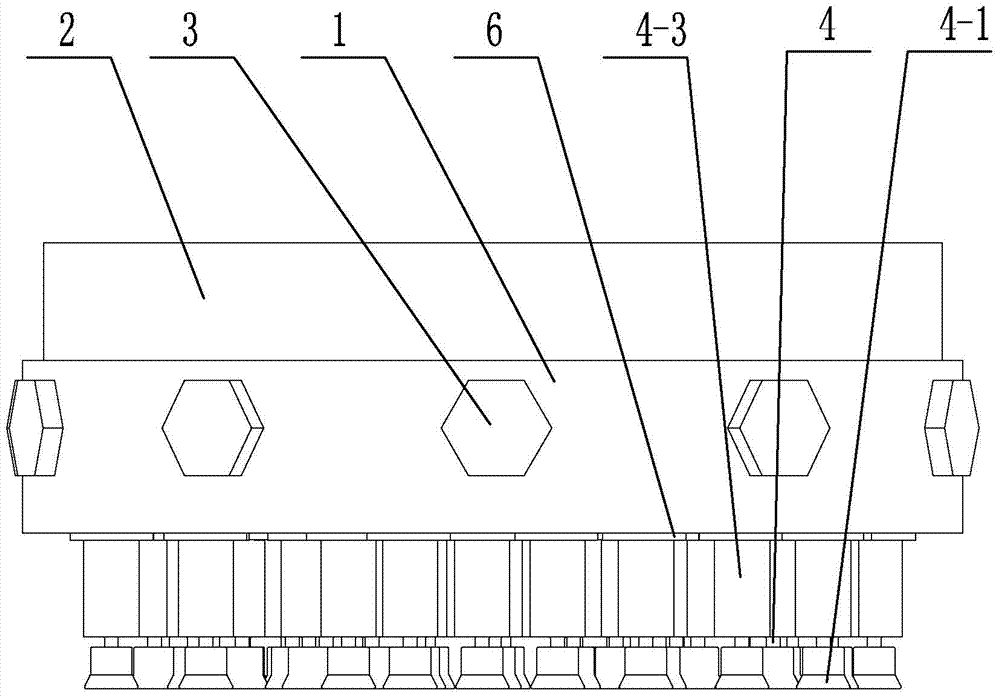

[0022] Specific implementation mode one: combine Figure 1 to Figure 11 Explain that a constant force grinding tool for grinding the mold surface of an automobile cover part according to this embodiment includes an upper base body 1, a lower base body 2, a plurality of connecting bolts 3, a plurality of constant force springs 5 and a plurality of sets of telescopic rods 4, Both the upper base 1 and the lower base 2 are disc-shaped, and the lower end surface of the upper base 1 is provided with a groove 1-1, and the groove 1-1 is set on the outside of the lower base 2, and the upper base 1 is connected by a plurality of connecting bolts 3 It is fixedly connected with the lower substrate 2, the middle part of the upper substrate 1 is provided with an upper connection through hole 1-2, the middle part of the lower substrate 2 is provided with a lower connection through hole 2-1, and the upper end surface of the upper substrate 1 is evenly arranged with multiple sets of limiters....

specific Embodiment approach 2

[0024] Specific implementation mode two: combination Figure 9 and Figure 11 Note that the constant force spring 5 in this embodiment includes two supporting springs 5-1 and a connecting frame 5-2, the two supporting springs 5-1 are connected through the connecting frame 5-2, and the supporting spring 5-1 is horizontally arranged on the column One side of body 4-3 lower end surface, the outside of the lower end surface of cylinder body 4-3 at the two ends of every group of expansion rod 4 is equipped with a supporting spring 5-1 by connecting frame 5-2 horizontal clamping. Other compositions and connection methods are the same as those in Embodiment 1.

[0025] This design ensures that each telescopic rod 4 is balanced in force on the premise of providing sufficient support for the telescopic rod 4 .

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 4 and Figure 5 Note that each telescopic rod 4 in this embodiment further includes a circlip 4-2, and the circlip 4-2 is arranged between the upper end surface of the cylinder 4-3 and the lower end surface of the grinding head 4-1. Other compositions and connection methods are the same as those in the second embodiment.

[0027] The jumper 4-2 is designed in this way to ensure that the cylinder 4-3 is stably connected with the grinding head 4-1, the telescopic rod 4 is stretchable and stable, and the grinding head 4-3 is stable in rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com