Laser safety protection method for laser processing equipment

A technology for laser processing and safety protection, applied in auxiliary devices, laser welding equipment, metal processing equipment, etc., can solve problems such as poor flexibility, safety protection loopholes, and cumbersome processes, and achieve the effect of easy construction and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

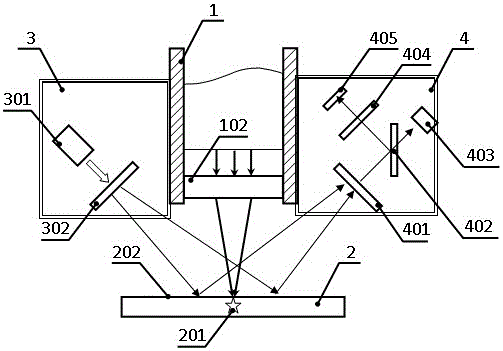

[0019] The laser safety protection method of the laser processing device of the present invention, such as figure 1 As shown, based on the principle of photoelectric detection, the optical fluorescent substance analysis technology and the photoelectric position detection technology are combined, and a weak light irradiation module and a photoelectric detection and analysis module are rigidly installed on the edge of the laser output machine of the laser processing head to realize the laser processing device. Laser safety protection.

[0020] The specific implementation steps of this embodiment are:

[0021] Step (1) Construct the weak light irradiation module 3 and the photoelectric detection and analysis module 4, the weak light irradiation module 3 is composed of a detection light source 301 and an illumination optical component 302, and the illumination optical comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com