Brazing furnace and brazing method for aluminum material

A brazing method and a technology of a brazing furnace, applied in welding equipment, welding equipment, electric heating devices, etc., can solve problems such as decreased flux function, clogging of electronic components, and stable quality of difficult brazing, so as to achieve good brazing, reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

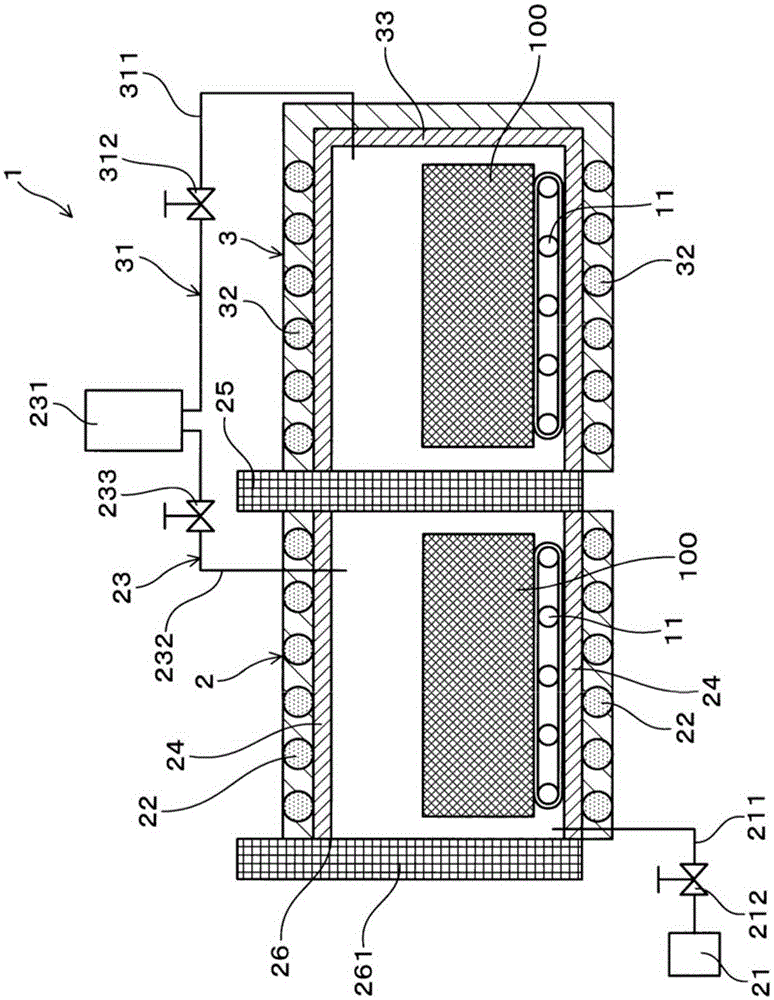

[0057] Examples of the above-mentioned brazing furnace and brazing method will be described using the drawings. Such as figure 1 As shown, the brazing furnace 1 is used for brazing a processed material 100 made of aluminum. The brazing furnace 1 has a preliminary heating chamber 2 and a brazing chamber 3 . The preliminary heating chamber 2 has: a vacuum pump 21 for depressurizing the chamber in a state where the material to be processed 100 is accommodated; a preliminary heating device 22 for preheating the material to be processed 100 under a reduced pressure atmosphere; A repressurization gas introduction device 23 for inert gas used to repressurize the chamber. The brazing chamber 3 has: a gas replacement device 31 for introducing an inert gas into the chamber; and a main heating device 32 for heating the material 100 to be processed to a brazing temperature.

[0058] The brazing furnace 1 of this example is an external heating type heating furnace in which a preliminary...

Embodiment 2

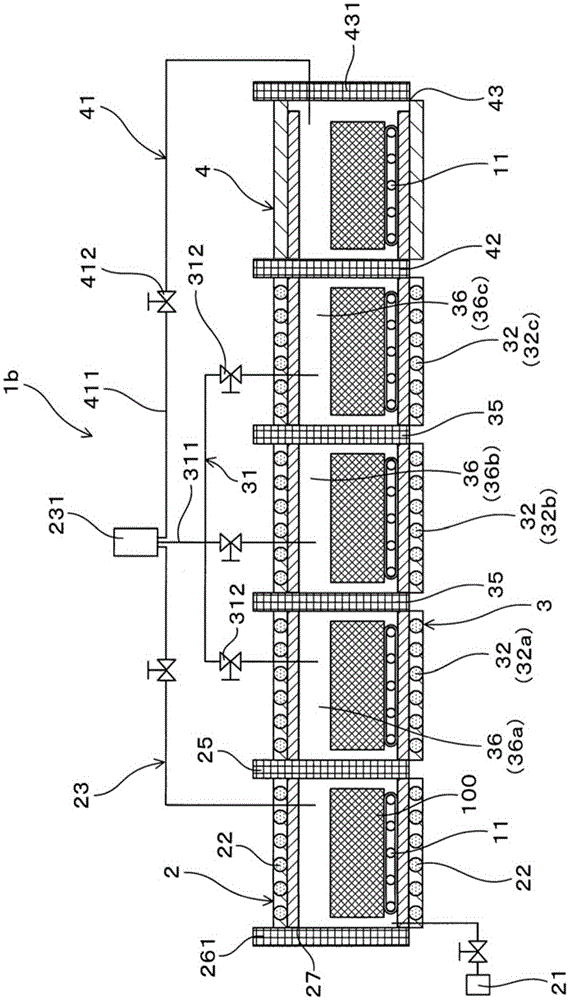

[0070] This example is an example of the brazing furnace 1b provided with three subunits 32a, 32b, 32c and the cooling chamber 4. Such as figure 2 As shown, the main heating device 32 in the brazing furnace 1b of this example has three sub-units 32a to 32c whose temperatures can be individually adjusted. The sub-units 32 a to 32 c are arranged along the conveyance direction of the material 100 to be processed. Moreover, the partition door 35 is provided openably and closably between adjacent subunits 32a-32c. In this example, the soaking area dimensions of the three heating zones 36 ( 36 a , 36 b and 36 c ) separated by the partition door 35 are all 300 mm in length, 200 mm in width and 200 mm in height. In addition, the replacement gas line 311 of the gas replacement device 31 enters each of the heating zones 36a to 36c.

[0071] In addition, the brazing furnace 1 b of this example has a cooling chamber 4 communicating with the brazing chamber 3 . In the brazing furnace ...

experiment example 1

[0076] This example is an example of performing a brazing test using the brazing furnace 1 of Example 1. FIG. In this example, as shown in Table 1, various manufacturing conditions were changed, and 12 kinds of honeycomb panels (test bodies E1 to E6 and test bodies C1 to C6) were produced. The configuration and experimental method of the material to be processed 101 will be described below.

[0077]

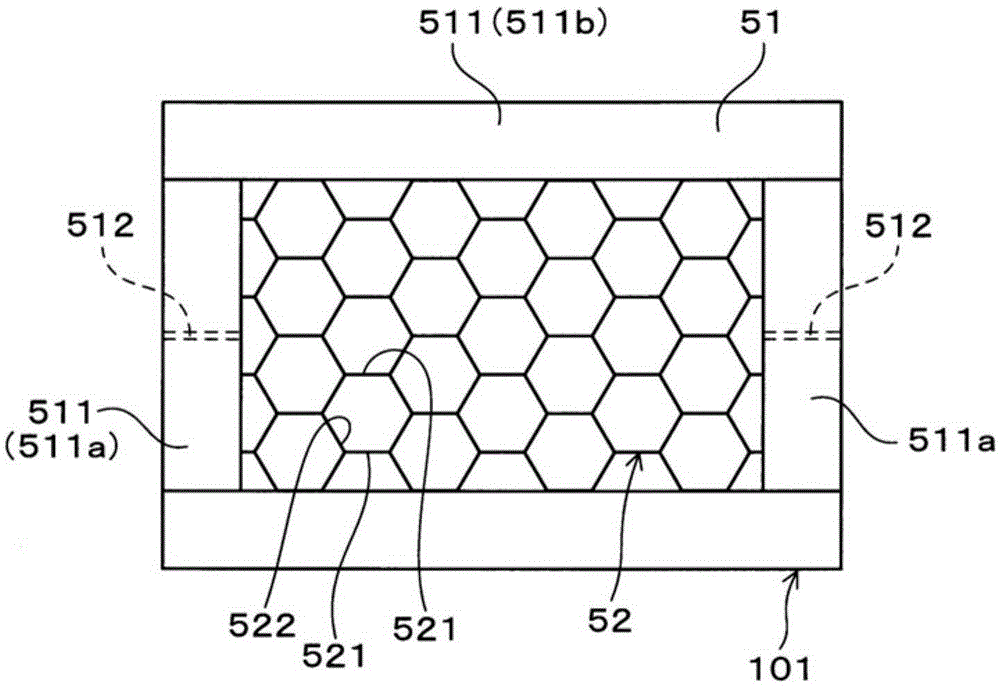

[0078] Such as image 3 As shown, the processed material 101 of this example has: a rectangular frame portion 51 composed of four hollow extruded shapes 511; a honeycomb core 52 disposed inside the frame portion 51; and a frame portion 51 and a honeycomb core 52 A panel (not shown) clamped from top to bottom. After assembling these parts into a predetermined shape (refer to Figure 4 ) After that, the honeycomb panel can be made by brazing.

[0079] The outer dimension of the frame portion 51 in the longitudinal direction (longitudinal direction) is 260 mm, and the outer di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com