A kind of soft water circulating water cooling mold device for edge milling wheel

A technology of water circulation and wheels, which is applied in the field of soft water circulation water-cooled mold devices for milling wheels, which can solve the problems of poor pinhole improvement, mold corrosion, and poor cooling effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation

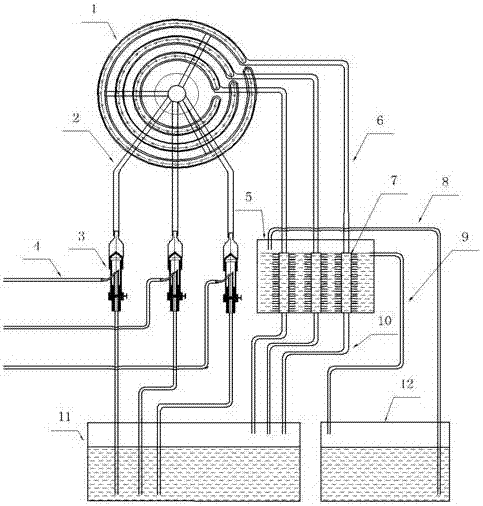

[0013] Such as figure 1 The structure schematic diagram of the present invention is shown, the device is composed of an annular water mist cooling pipe 1, a water mist generator 3, a cooling water treatment tank 5, a cooling water storage tank 12, and a softened water storage tank 11.

[0014] Such as figure 2 Shown is a structural schematic diagram of the annular water mist cooling pipe of the present invention, which is composed of an outer layer pipe 13 , an inner layer pipe 14 , a water mist spray hole 15 , and a water mist flow divider 16 .

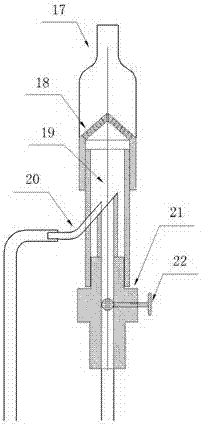

[0015] Such as image 3 Shown is a schematic structural diagram of the water mist generator of the present invention, which is composed of a water mist outlet joint 17, a conical water mist nozzle 18, a water vapor mixing chamber 19, a compressed air joint 20, a water pipe joint 21, and a water intake regulating valve 22.

[0016] Such as Figure 4 Shown is the assembly diagram of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com