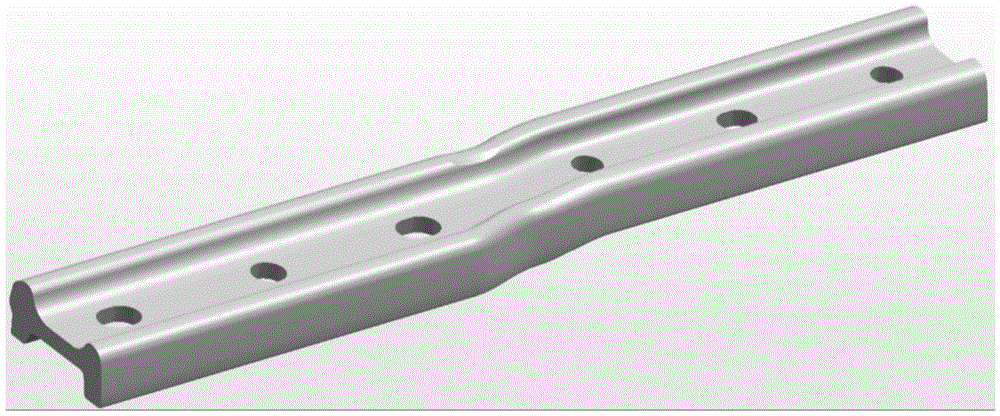

Manufacturing method for special-shaped fishplate and dies

A manufacturing method and fishplate technology, applied in the field of machinery, can solve the problems of poor density, environmental pollution, low yield, etc., and achieve the effects of improving production efficiency, reducing production costs, and stabilizing comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

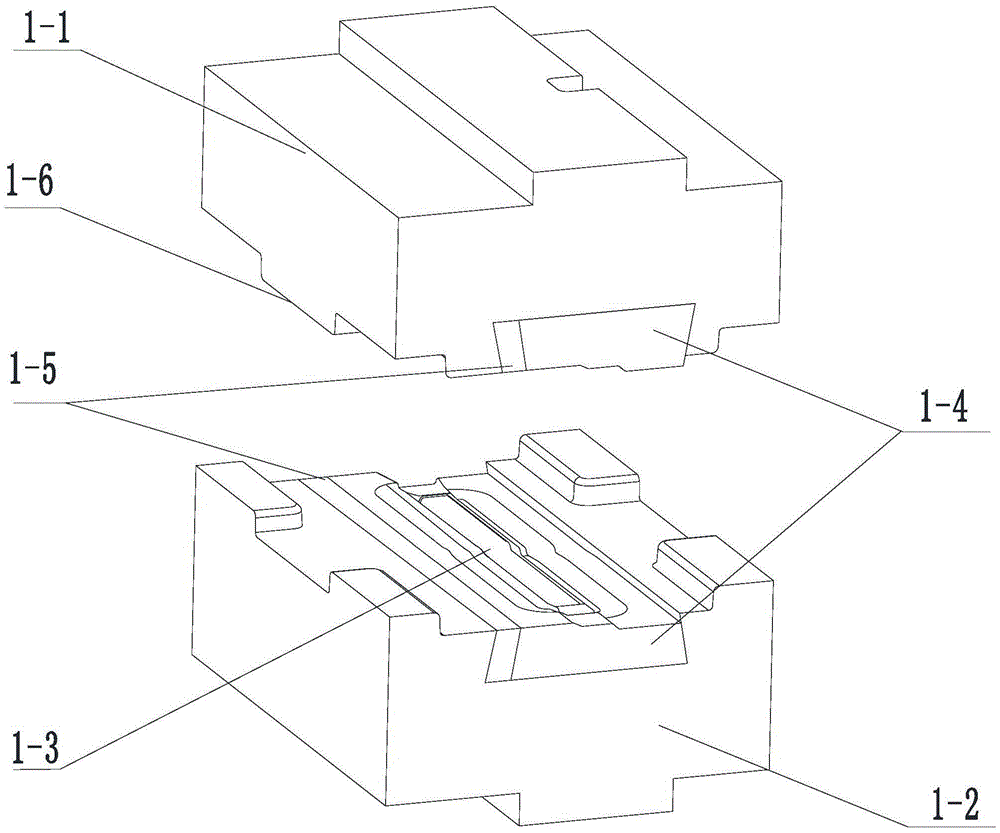

[0035] like figure 1 As shown, the present invention provides a special-shaped fishplate forging die, including an upper die 1-1 and a lower die 1-2, wherein a mold is arranged between the upper die 1-1 and the lower die 1-2. A cavity 1-3, the cavity 1-3 is provided with an insert core 1-4, and the insert core 1-4 is respectively fixed with the upper mold 1-1 or the lower mold 1-2 by wedge iron 1-5 Connected, the upper mold 1-1 and the lower mold 1-2 are provided with locks that cooperate with each other, so as to be more fastened when the molds are closed.

[0036] In yet another embodiment, the in-cavity draft angle of the insert core 1-4 is 4.8-5.3 degrees, and the out-cavity draft angle is 2.7-3.3 degrees. Both the bridge portion and the flash bin are made by known techniques.

[0037] In yet another embodiment, the upper and lower mold bases are made of ordinary hot work die steel (such as 5CrNiMo), and the insert core is made of high-end hot work die steel (such as H13...

Embodiment 2

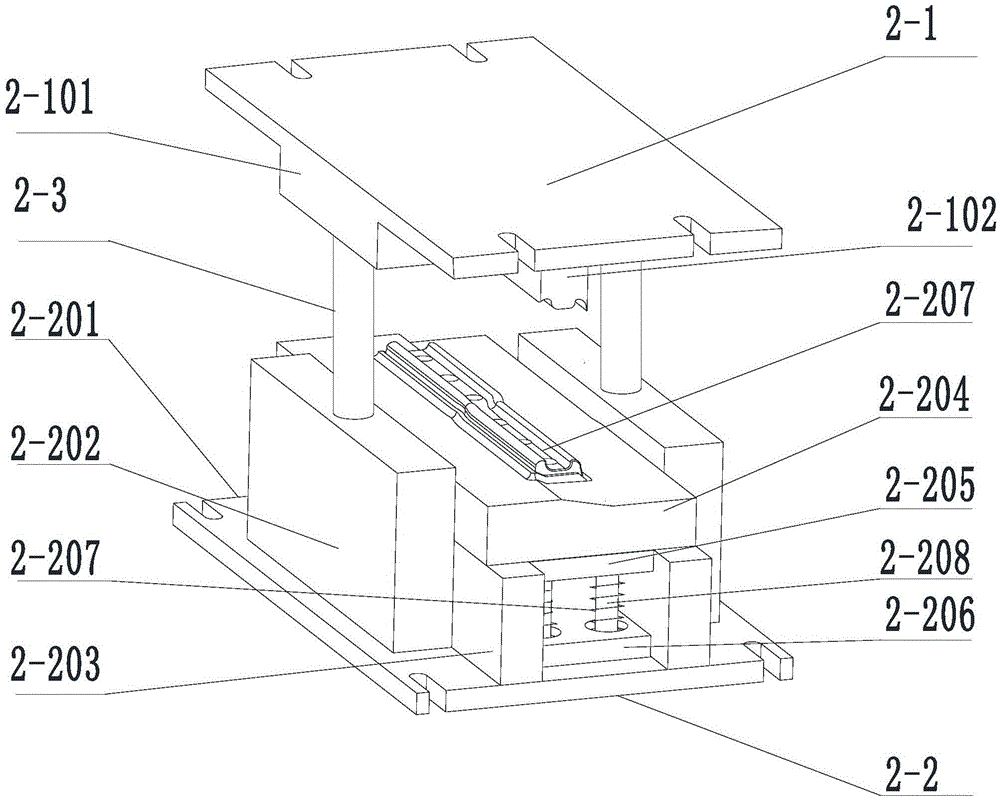

[0039] like figure 2 As shown, the present invention provides a composite mold for punching, trimming, and leveling a special-shaped fishplate, including an upper mold part 2-1 and a lower mold part 2-2, wherein,

[0040] The upper mold part 2-1 includes an upper template 2-101 and a punch 2-102, and the punch 2-102 is connected to the middle of the upper template 2-101;

[0041] The lower mold part 2-2 includes a base 2-201, a support plate 2-202, a support block 2-203, a die 2-204, a supporting plate 2-205, a backing plate 2-206 and an ejector 2-207 , above the base 2-201 are provided with two symmetrical support plates 2-202, between the two support plates 2-202 are provided two support blocks 2-203, above the support blocks 2-203 are connected Die 2-204; the die 2-204 corresponds to the punch 2-102 and is located in the middle of the lower die part 2-2; a supporting plate 2-205 is provided below the die 2-204 and a backing plate 2-206, the upper plane of the supporting ...

Embodiment 3

[0045] To manufacture 136RE-115RE high-strength special-shaped fishplates for export to North America, first process the forging die and punching, trimming and leveling compound die of this model;

[0046] (1) Raw material cutting:

[0047] According to the specifications, it is preferable to use 55# round steel Φ70mm, calculate the required round steel blanking weight of 33kg, and transfer to the next step for use;

[0048] (2) Intermediate frequency heating:

[0049] Put the above-mentioned raw materials into the intermediate frequency induction heating furnace for heating, set the heating temperature of the blank to 1180 ° C, and the heating cycle of a single piece is 4 minutes;

[0050] (3) Die forging:

[0051] First, install the prepared forging die on an 8-ton die forging hammer, and preheat the forging die evenly to 300 °C in advance; the mold cavity is evenly sprayed with graphite milk that is easy to demould, and the heated material is placed in the place. The for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com