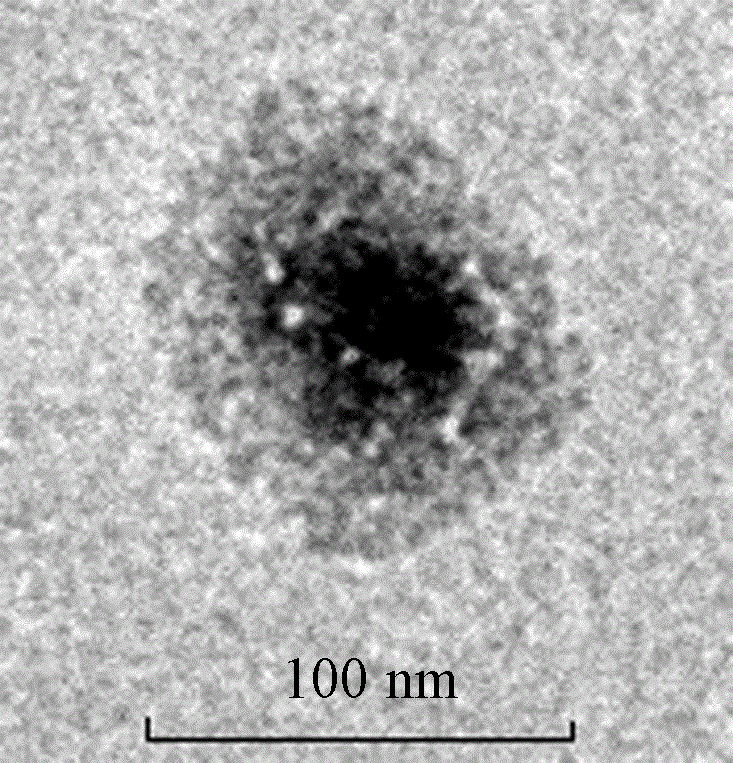

Preparation of superparamagnetic Fe3O4-PAMAM-ZnO / TiO2 nanoparticles with core-shell composite structure

A technology of fe3o4-pamam-zno and nanoparticles, applied in organic compound/hydride/coordination complex catalysts, chemical/physical processes, special compound water treatment, etc., can solve crystal shell difficulties and increase particle size , the increase of hydrophobicity on the surface of the particles, etc., to avoid the decrease of the specific surface area, reduce the direct contact area, and the effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step (1): The surface of Fe fully coated with PAMAM dendrimers 3 o 4 -Preparation of PAMAM nanoparticle colloidal solution: to a concentration of 1×10 -5 The mol / L end group of the 6th generation PAMAM dendrimer aqueous solution with ester group was fed with nitrogen gas and stirred for 30 minutes, then added the iron salt mixed solution, the concentration of ferric chloride in the iron salt mixed solution was 0.1mol / L, trichloro The ratio of the amount of substance of iron oxide and ferric chloride is 2, and the amount of ferric salt mixed solution is 120:1 as a standard with the ratio of the amount of substance of ferric iron and PAMAM dendrimers, and nitrogen gas is fed under room temperature and After mechanical stirring for 4 hours, the iron ions and the dendrimers are fully coordinated, then the temperature of the water bath is adjusted to 90°C, the stirring speed is increased to above 800r / min, and the aqueous sodium hydroxide solution with a concentration of 0....

Embodiment 2

[0022] Step (1): The surface of Fe fully coated with PAMAM dendrimers 3 o 4 -Preparation of PAMAM nanoparticle colloidal solution: to a concentration of 1×10 -5 The mol / L end group of the 6th generation PAMAM dendrimer aqueous solution with hydroxyl group was fed with nitrogen gas and stirred for 30 minutes, then the iron salt mixture was added, the concentration of ferric chloride in the iron salt mixture was 0.1mol / L, and the trichloride The ratio of the amount of iron to ferrous sulfate is 2, and the amount of the ferric salt mixture is based on the ratio of 100:1 to the ratio of ferric iron to PAMAM dendrimers. Nitrogen gas is introduced at room temperature and stirred mechanically. After 4 hours, fully coordinate the iron ions with the dendrimers, then adjust the temperature of the water bath to 90°C, increase the stirring speed to above 800r / min, and add dropwise an aqueous sodium hydroxide solution with a concentration of 0.1mol / L until the pH is 11. After continuous ...

Embodiment 3

[0025] Step (1): The surface of Fe fully coated with PAMAM dendrimers 3 o 4 -Preparation of PAMAM nanoparticle colloidal solution: to a concentration of 1×10 -5 The mol / L terminal group of the 5th generation PAMAM dendrimer aqueous solution with carboxyl group was fed with nitrogen gas and stirred for 30 minutes, then the iron salt mixture was added, the concentration of ferric chloride in the iron salt mixture was 0.1mol / L, and the trichloride The ratio of the amount of iron to ferrous sulfate is 2, and the amount of ferric salt mixture is based on the ratio of 60:1 to the ratio of ferric iron to PAMAM dendrimers. Nitrogen gas is introduced at room temperature and stirred mechanically. After 4 hours, fully coordinate the iron ions and the dendrimers, then adjust the temperature of the water bath to 80°C, increase the stirring speed to above 800r / min, and add dropwise an aqueous sodium hydroxide solution with a concentration of 0.1mol / L until the pH is 10. After continuous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com