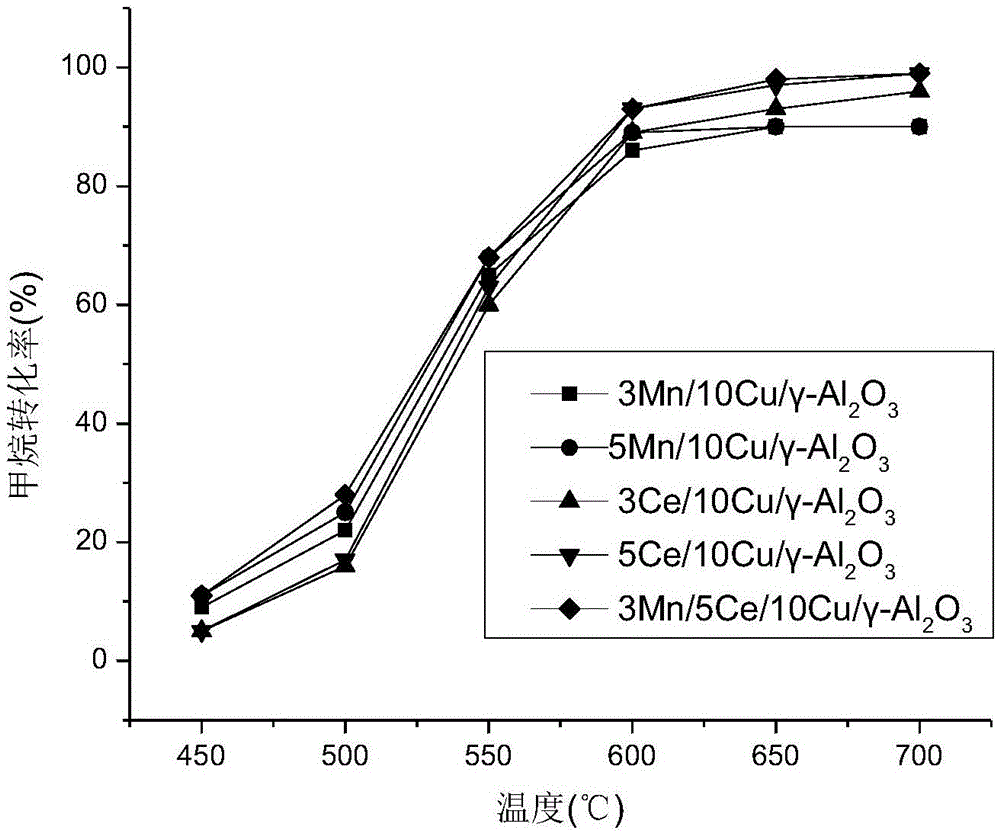

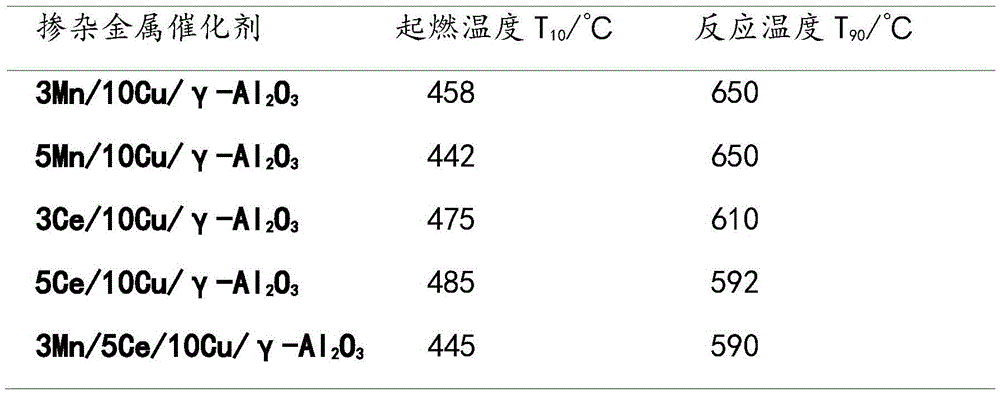

Mn and Ce doped Cu based methane combustion catalyst and preparation method thereof

A methane combustion and catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of expensive precious metal materials, general high-temperature catalytic activity, and inability to use large-scale use, etc. Low material cost, good catalytic activity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of 5Mn / 10Cu / γ-Al 2 o 3

[0027] First wash the carrier γ-Al with distilled water 2 o 3 The particles were then dried in an oven at a temperature of 110 °C for 4 h, and then calcined in a muffle furnace at a temperature of 400 °C for 2 h to remove impurities on the surface of the carrier. Take out 8.5g of γ-Al 2 o 3 Pellets were placed in a beaker, and deionized water was slowly added to the beaker until the γ-Al 2 o 3 Particle adsorption saturation, record the volume of deionized water used, determine 8.5g γ-Al 2 o 3 The water absorption capacity is 7.1ml. Put 8.5g γ-Al 2 o 3 The particles are immersed in 7.1 ml of manganese nitrate solution (which contains 1.63 g of manganese nitrate powder). After soaking for 2 hours, take out the carrier particles and put them in a beaker, place them in the air for 10 hours, and put the carrier-containing beaker into a drying box. After drying at 110°C for 12 hours, place it in a muffle furnace for ...

Embodiment 2

[0028] Example 2: Preparation of 5Ce / 10Cu / γ-Al 2 o 3

[0029] Determine 8.5g γ-Al 2 o 3 The water absorption capacity is 7.1ml. Put 8.5g γ-Al 2 o 3 The particles are immersed in 7.1 ml of cerium nitrate solution (which contains 1.55 g of cerium nitrate powder). After 2 hours of immersion, the carrier particles are taken out and put into a beaker, and placed in the air for 10 hours, and the beaker containing the carrier is put into a drying box After drying at 110°C for 12 hours, place it in a muffle furnace for calcination at 600°C for 4 hours, and cool naturally to obtain the intermediate catalyst 5Ce / γ-Al 2 o 3 ; The intermediate catalyst 5Ce / γ-Al 2 o 3 Put 7.1 milliliters of copper nitrate solution (which contains 3.78 g of copper nitrate powder) for impregnation, take out the intermediate catalyst and put it in a beaker after impregnating for 2 hours, place it in the air and let it stand for 10 hours, put the beaker containing the intermediate catalyst in the dryi...

Embodiment 3

[0030] Example 3: Preparation of 3Mn / 10Cu / γ-Al 2 o 3

[0031] 3Mn / 10Cu / γ-Al 2 o 3 The preparation method is the same as in Example 1. The mass percentage of the ingredients is: 3% Mn, 10% Cu, 87% γ-Al 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com