Special power supply device for direct current smelting

A special power supply and rectifier technology, which is applied to the output power conversion device, the circuit arrangement on the support structure, and the conversion of AC power input to DC power output, etc., to achieve good results, avoid hidden troubles, and improve thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

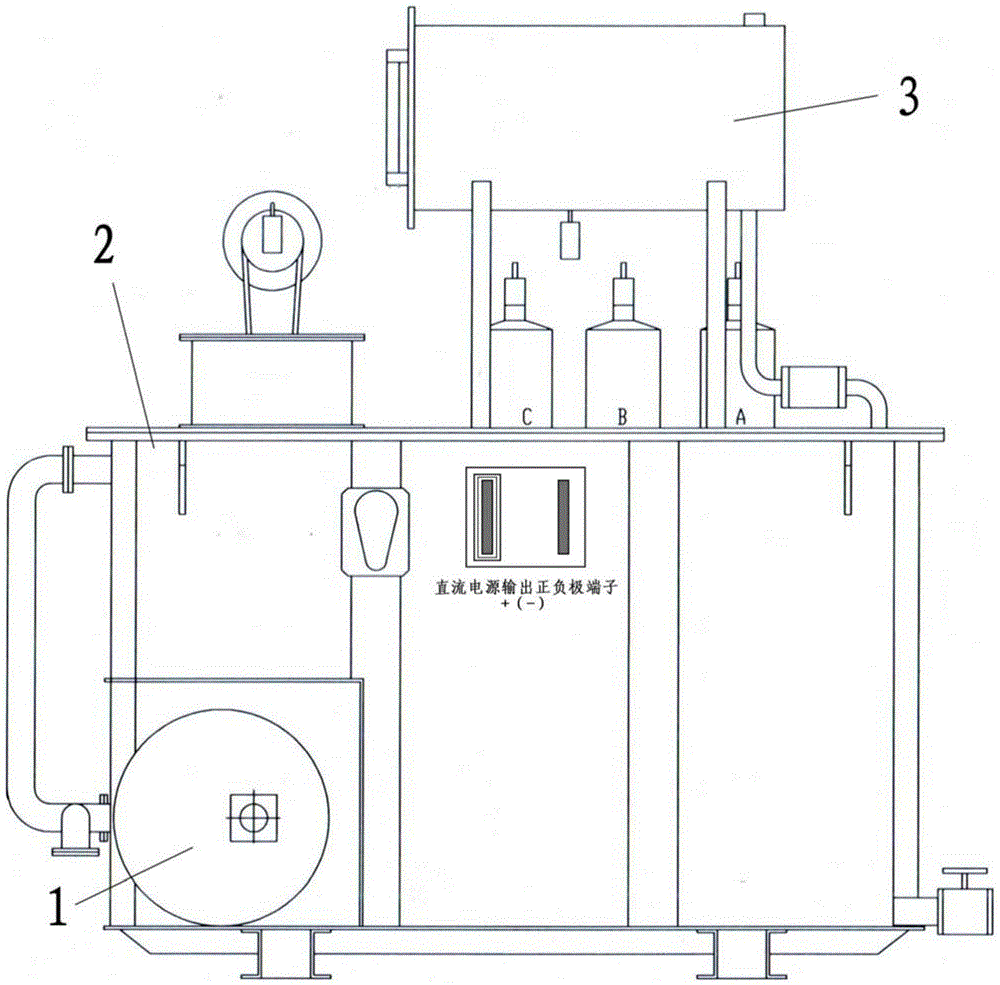

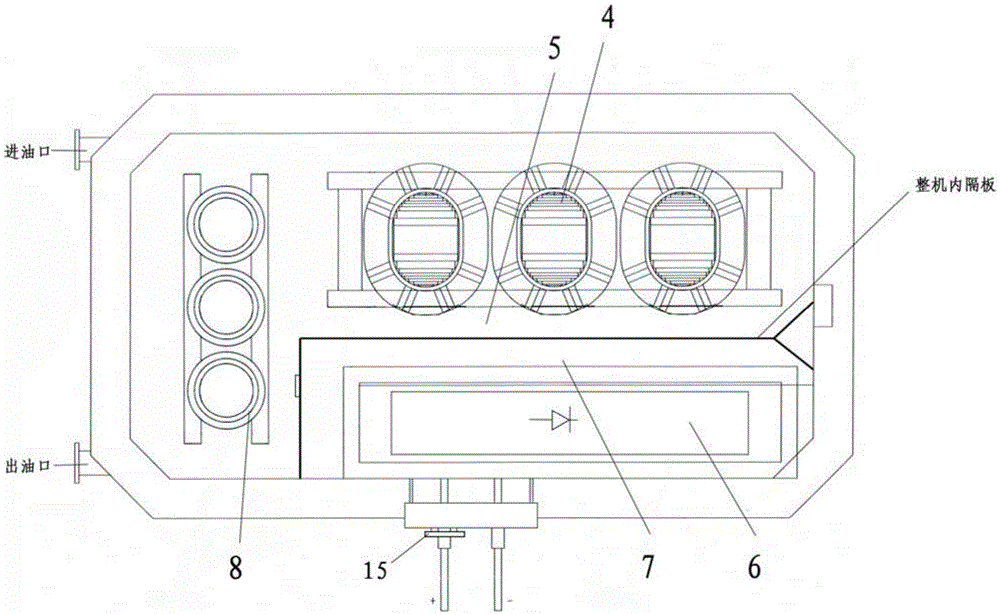

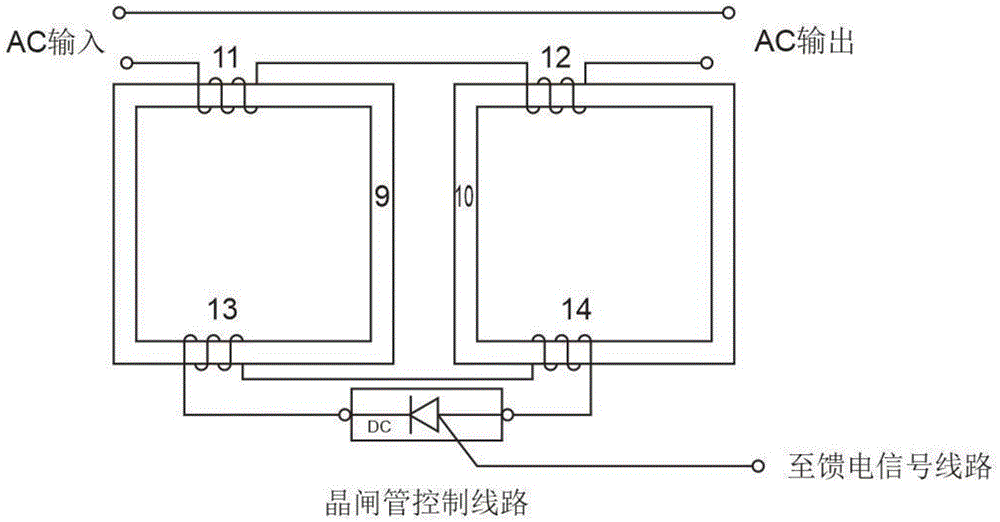

[0030] Such as Figure 1-2 , the special power supply device for direct current smelting, including the whole machine box 1, the whole machine box 1 includes a "7" shaped transformer oil chamber 5 and a "1" shaped rectifier oil chamber 7, the transformer oil chamber 5 and the rectifier oil chamber The cavity 7 forms an overall rectangle. The transformer oil cavity 5 is provided with a transformer 4 and a current sensing limiter 8, and the transformer 4 and the current sensing limiter 8

[0031] Connected in series, the rectifier 6 is installed in the rectifier oil cavity 7, the low-voltage output end of the transformer 4 is connected to the bus bar of the rectifier 6 component, the output end of the bus bar is connected through the DC positive and negative conductive copper bar, and the DC positive and negative copper bar The other end can be directly connected with the anode and cathode of DC smelting through the whole machine box body 1. The outer side of the box body 1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com