Surface protection method for samarium-cobalt magnet workpiece

A workpiece surface, samarium cobalt magnet technology, applied in electrical components, metal material coating process, inductance/transformer/magnet manufacturing and other directions, can solve problems such as magnetic performance attenuation, to improve magnetic performance attenuation, excellent high temperature stability, The effect of improving the protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, a NiCrAlY protective film is deposited on the surface of a samarium-cobalt magnet workpiece by magnetron sputtering, and the composition of the protected samarium-cobalt magnet is Sm(Co 0.68 Fe 0.22 Cu 0.08 Zr 0.02 ) 7.2 . Including the following steps

[0038] (1) Choose two Ni 30 Cr 8 Al 0.5 The Y alloy target is installed on the magnetron sputtering source in the vacuum chamber;

[0039] (2) Polish the surface of the samarium-cobalt magnet workpiece with SiC water sandpaper according to 280#, 600#, 1200#, 2000# in sequence, and then polish it with aluminum oxide solution on the flannelette; then use alcohol and acetone to ultrasonically clean the workpiece in turn 10min;

[0040] (3) Place the samarium cobalt magnet workpiece on the sample turntable after drying;

[0041] (4) First use the mechanical pump to pre-evacuate to less than 20Pa, then turn on the molecular pump to evacuate, so that the vacuum degree in the vacuum chamber reache...

Embodiment 2

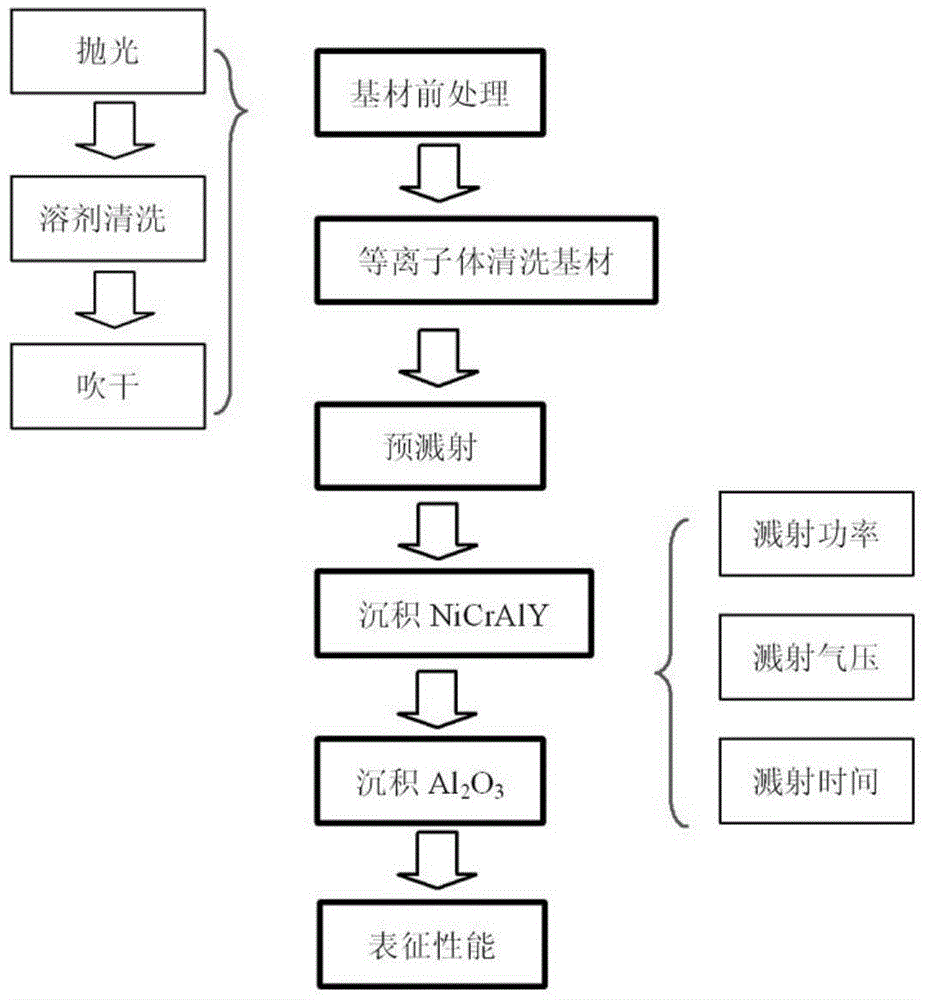

[0046] figure 1 It is a flow chart of the method for protecting the surface of a samarium-cobalt magnet workpiece in this embodiment.

[0047] In this embodiment, the magnetron sputtering method is used to deposit NiCrAlY+Al on the surface of the samarium cobalt magnet workpiece. 2 o 3 Protective film, the composition of the protected samarium cobalt magnet is Sm(Co 0.68 Fe 0.22 Cu 0.08 Zr 0.02 ) 7.2 . Including the following steps:

[0048] (1) Choose two Ni 30 Cr 8 Al 0.5 The Y alloy target is installed on the magnetron sputtering source in the vacuum chamber;

[0049] (2) Two Al targets are selected and installed on the magnetron sputtering source in the vacuum chamber

[0050] (3) Polish the surface of the samarium-cobalt magnet workpiece with SiC water sandpaper according to 280#, 600#, 1200#, 2000# in sequence, and then polish it with aluminum oxide solution on the flannelette; then use alcohol and acetone to ultrasonically clean the workpiece 10min;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com