Extraction method of bovine tendon collagen

A technology of tendon collagen and collagen, which is applied in the preparation method of peptides, chemical instruments and methods, animal/human protein, etc., can solve the defects of mechanical properties and biological stability of collagen materials, undisclosed process parameters, and unreachable Effectiveness and other issues, to achieve the effect of strong hydrophilicity, high extraction efficiency, and good product elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

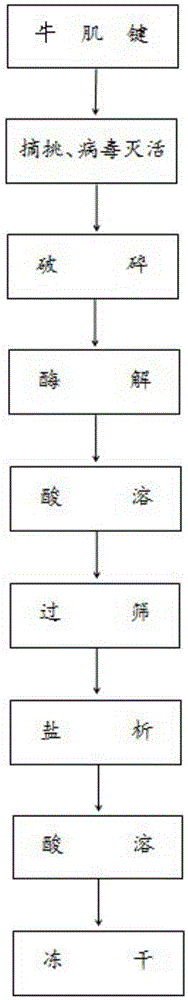

Method used

Image

Examples

Embodiment 1

[0034] All operations in Example 1 were carried out in a sterile 10,000-level purification area, and the subpackaging and freeze-drying operations were all carried out in a local 100-level purification area, and the operations performed all met the operating requirements of the clean area.

[0035] (1) Take 2kg bovine tendon;

[0036] (2) Stir and wash the tendon with 2 times the volume of 0.3% (V / V) polysorbate 80 aqueous solution for 10 minutes, and rinse the tendon with water until the solution is clear;

[0037] (3) Stir and clean the tendon with 2 times the volume of 0.005M sodium hydroxide solution for 10 minutes, and rinse the tendon with water until the solution is neutral;

[0038] (4) Soak the tendon in water, and remove the adherent film on the tendon with curved scissors;

[0039] (5) Rinse with water until there is no debris;

[0040] (6) Arrange the cleaned tendons neatly, and freeze at -30°C for 30 minutes;

[0041] (7) Take out the tendon, cut it into 1-2mm ...

Embodiment 2

[0053] All operations in Example 2 were carried out in a sterile ten-thousand-grade purification area, wherein subpackaging and freeze-drying operations were all carried out in a local one-hundred-grade purification area, and the operations performed all met the operating requirements of the clean area.

[0054] (1) Take by weighing 5kg bovine tendon;

[0055] (2) Stir and wash the tendon with 2 times the volume of 0.3% (V / V) polysorbate 80 aqueous solution for 10 minutes, and rinse the tendon with water until the solution is clear;

[0056] (3) Stir and clean the tendon with 2 times the volume of 0.005M sodium hydroxide solution for 10 minutes, and rinse the tendon with water until the solution is neutral;

[0057] (4) Soak the tendon in water, and remove the adherent film on the tendon with curved scissors;

[0058] (5) Rinse with water until there is no debris;

[0059] (6) Arrange the cleaned tendons neatly, and freeze at -30°C for 30 minutes;

[0060] (7) Take out the ...

Embodiment 3

[0072] All operations in Example 3 were carried out in a ten thousand-class purification area, wherein subpackaging and freeze-drying operations were all carried out in a local one-hundred-class purification area, and the operations performed all met the operating requirements of the clean area.

[0073] (1) Take by weighing 10kg bovine tendon;

[0074] (2) Stir and wash the tendon with 2 times the volume of 0.3% (V / V) polysorbate 80 aqueous solution for 10 minutes, and rinse the tendon with water until the solution is clear;

[0075] (3) Stir and clean the tendon with 2 times the volume of 0.005M sodium hydroxide solution for 10 minutes, and rinse the tendon with water until the solution is neutral;

[0076] (4) Soak the tendon in water, and remove the adherent film on the tendon with curved scissors;

[0077] (5) Rinse with water until there is no debris;

[0078] (6) Arrange the cleaned tendons neatly, and freeze at -30°C for 30 minutes;

[0079] (7) Take out the tendon,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com