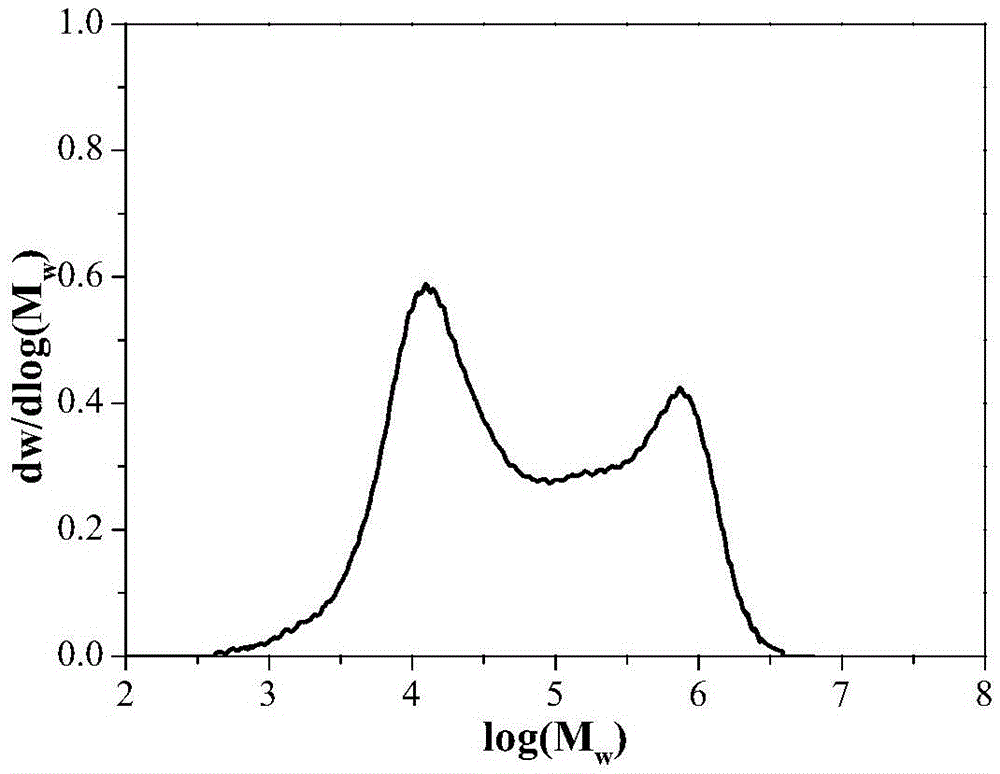

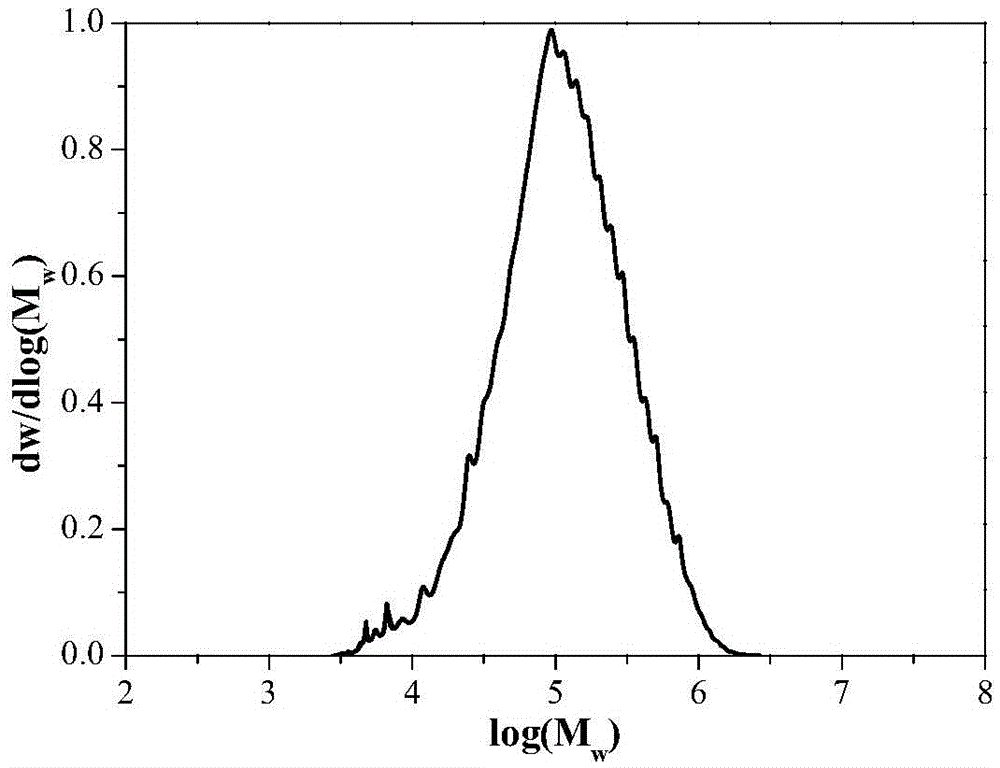

Bimodal molecular weight distributed cycloolefin copolymer and preparation method thereof

A technology of cycloolefin copolymer and molecular weight distribution, which is applied in the field of preparation of bimodal molecular weight distribution cycloolefin copolymer by solution polymerization, to achieve excellent mechanical properties, excellent processing performance, and avoid gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

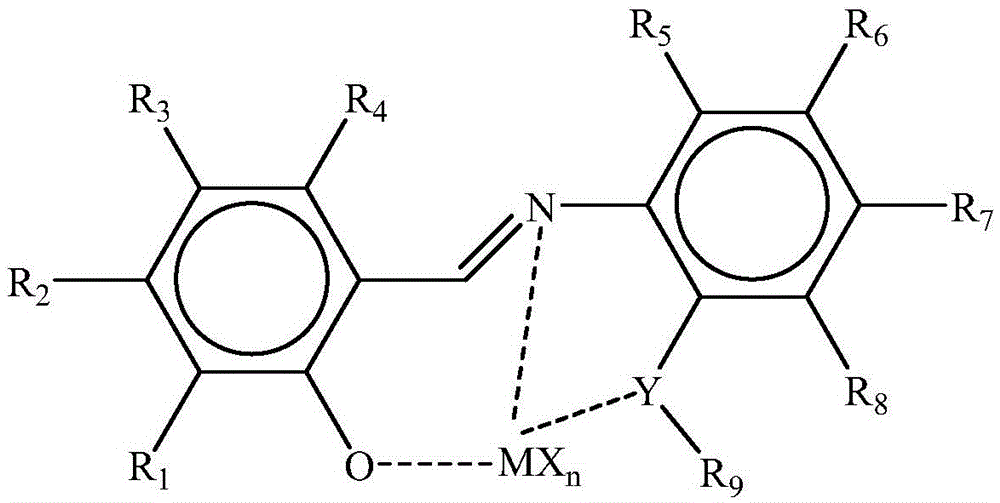

Embodiment 1

[0043] A 100 ml tank reactor was used in this example. Dissolve 8.9 milliliters of refined norbornene (0.09 mol) in 50 milliliters of refined toluene to form a solution, add the solution to a reactor flushed with nitrogen in advance, and press ethylene (1 bar) several times to make the solution saturated with ethylene, Under the condition of 70°C temperature, 1 bar and stirring, add 0.1 mmol chain transfer agent (triethylaluminum and diethyl zinc molar ratio 1:1, that is, triethyl aluminum and diethyl zinc each 0.05 mg) mol), 1.8 ml of a toluene solution with a concentration of 1.72 mol / L methylaluminoxane, 1 μmol of salicylidene 2-methoxyaniline titanium trichloride and 1 μmol of rac-vinyl (diindene base) zirconium dichloride double-active center composite catalyst, the polymerization process is supplemented by metering ethylene, and the control pressure is 1 bar.

[0044] After 30 minutes of reaction, the reaction solution was poured into ethanol containing 15% (volume %) h...

Embodiment 2

[0046] A 100 ml tank reactor was used in this example. Dissolve 14.8 milliliters of refined vinyl norbornene (0.11 mol) in 50 milliliters of refined toluene to form a solution, add the solution to the reactor flushed with nitrogen in advance, and press ethylene (1 bar) several times to make the solution saturated with ethylene Saturation, at 70°C, 1 bar and stirring, add 0.1 mmol of chain transfer agent (trimethylaluminum and diisobutyl zinc molar ratio 1:20), 1.8 ml concentration of 1.72 mol / L A toluene solution of methylaluminoxane, 2 micromoles of 3,5-di-tert-butylsalicylidene 2-mercaptoaniline titanium trichloride and 1 micromoles of benzhydryl (cyclopentadienyl) (fluorenyl ) double active center composite catalyst of zirconium dichloride, during the polymerization process, ethylene is added by supplementary metering, and the control pressure is 1 bar.

[0047] After 30 minutes of reaction, the reaction solution was poured into ethanol containing 15% (volume %) hydrochlor...

Embodiment 3

[0049] A 100 ml tank reactor was used in this example. Dissolve 8 milliliters of refined norbornene (0.08 mol) in 50 milliliters of refined toluene to form a solution, add the solution to the reactor flushed with nitrogen in advance, and punch ethylene (1 bar) several times to make the solution saturated with ethylene, Under the conditions of temperature of 60°C, 1 bar and stirring, 0.3 mmol of chain transfer agent (molar ratio of triethylaluminum and dimethyl zinc is 1:50), 3.8 ml of methylaluminum oxide with a concentration of 1.72 mol / L were added successively. Two active site complexes of alkanes in toluene, 1 μmol of salicylidene 2-mercaptoaniline titanium trichloride and 2 μmol of rac-dimethylsilylbis(2-methylindenyl)zirconium dichloride Catalyst, the polymerization process is supplemented by metering ethylene, and the control pressure is 1 bar.

[0050] After 60 minutes of reaction, the reaction solution was poured into ethanol containing 15% (volume %) hydrochloric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com