Organic light-emitting device

An electroluminescent device and luminescent technology, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of difficult preparation and high voltage, and achieve the effects of improving efficiency, reducing equipment cost, and reducing the number of evaporation sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

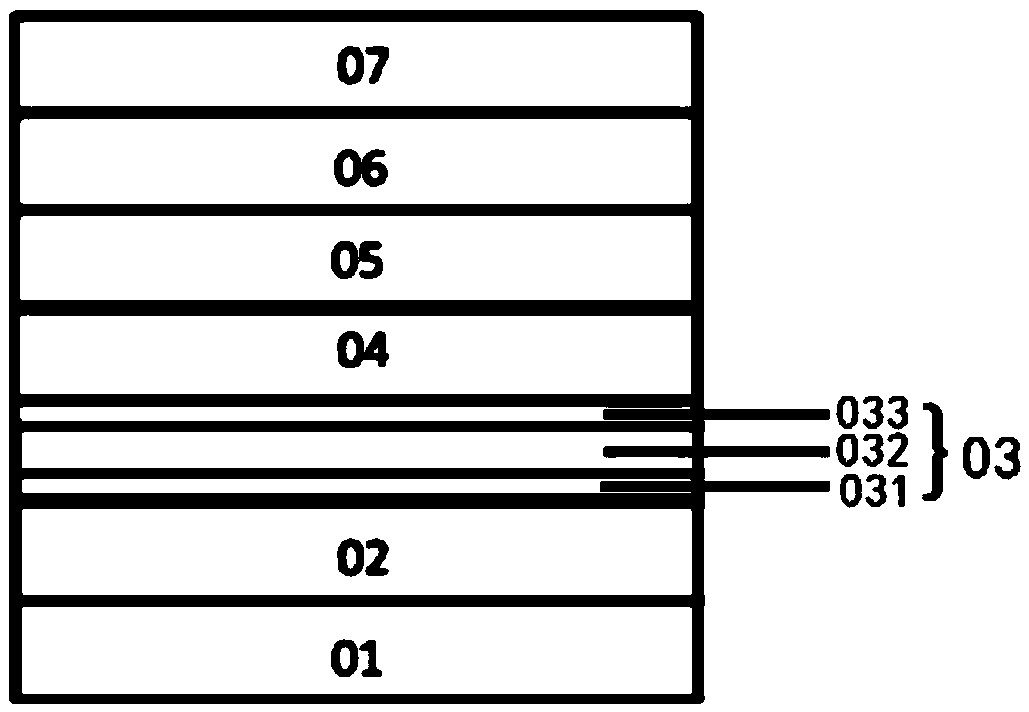

[0056] ITO / HAT-CN(10nm) / NPB(5nm) / NPB: Compound 1-1(50nm) / Compound 1-1(5nm) / Compound 3-1(30nm) / Bphen(40nm) / LiF(1nm) / Al (150nm).

[0057] Hole injection layer (HAT-CN), first hole material layer (NPB), transition layer (NPB: compound 1-1), second hole material layer (compound 3-1), light emitting layer (compound 3- 1), electron transport layer (Bphen), electron injection layer (LiF), second electrode layer (cathode Al).

Embodiment 2

[0059] ITO / HAT-CN(10nm) / NPB(5nm) / NPB: Compound 1-6(50nm) / Compound 1-6(5nm) / Compound 3-1(300) / Bphen(40nm) / LiF(1nm) / Al (150nm).

[0060] Hole injection layer (HAT-CN), first hole material layer (NPB), transition layer (NPB: compound 1-6), second hole material layer (compound 1-6), light emitting layer (compound 3- 1), electron transport layer (Bphen), electron injection layer (LiF), second electrode layer (cathode Al).

Embodiment 3

[0062] ITO / HAT-CN(10nm) / NPB(10nm) / NPB: Compound 1-6(40nm) / Compound 1-6(10nm) / Compound 3-1(30nm) / Bphen(40nm) / LiF(1nm) / Al (150nm).

[0063] Hole injection layer (HAT-CN), first hole material layer (NPB), transition layer (NPB: compound 1-6), second hole material layer (compound 1-6), light emitting layer (compound 3- 1), electron transport layer (Bphen), electron injection layer (LiF), second electrode layer (cathode Al).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com