Compound and organic electroluminescence device

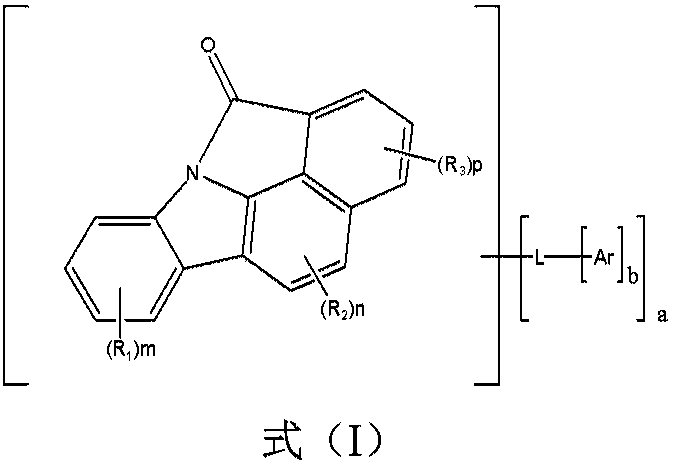

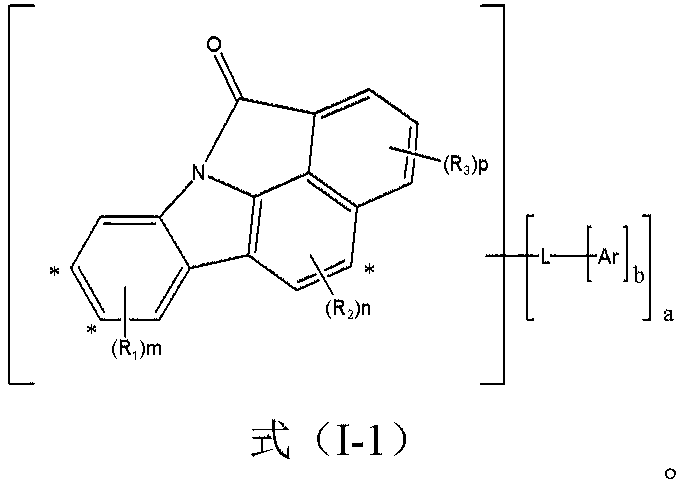

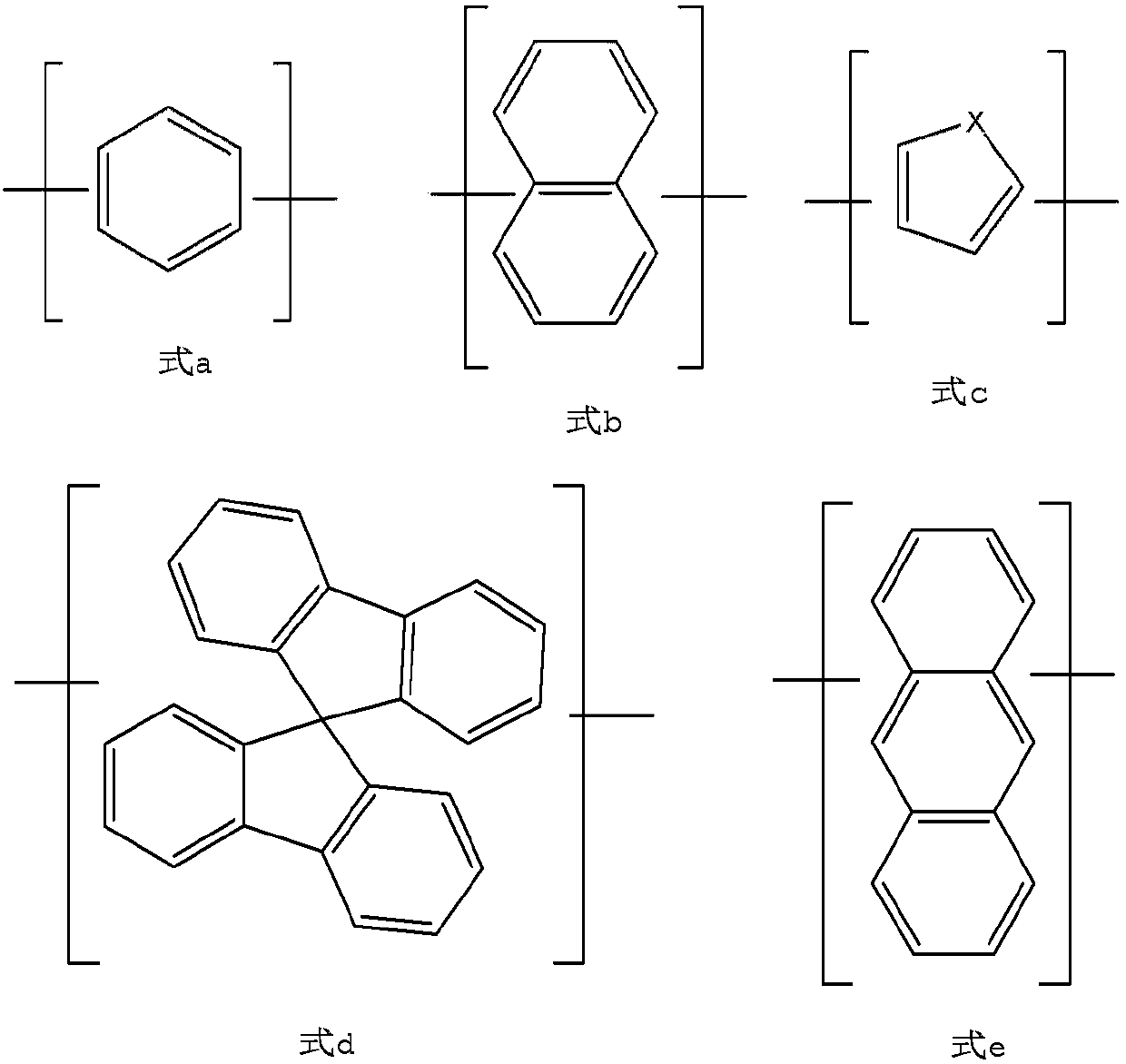

A compound, electromechanical technology, applied in the application of the compound in the field of organic electroluminescence display and lighting technology, and the field of organic electroluminescence devices, can solve the problems of unfavorable energy saving, increased device operating voltage, affecting power efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 2

[0056] Synthesis Example 2: Synthesis of Intermediate M2

[0057]

[0058] M1 (31mmol, 10g), palladium acetate (1%, 0.07g), tricyclohexylphosphine tetrafluoroborate (3%, 0.34g) and DMF (200 milliliters) are mixed, heated to 130 degree of reaction for 3 hours, reaction After the end, cool to room temperature, add 400 ml of pure water, extract with ethyl acetate, wash the organic phase with 300 ml of water, concentrate the organic phase under reduced pressure, mix with silica gel and pass through a silica gel column (eluent: petroleum ether: ethyl acetate=2 : 1), to obtain compound M2 (6.1 g, 80.1%).

Synthetic example 3

[0059] Synthesis Example 3: Synthesis of Intermediate M3

[0060]

[0061] Under nitrogen protection, 1,8-naphtholactam (59.2mmol, 10g), 1-bromo-2-iodo-4 nitrobenzene (59.2mmol, 19.4g) was added in a 500ml three-necked flask, sodium tert-butoxide ( 118.4mmol, 11.2g), Pd 2 (dba) 3 (0.59mmol, 0.54g), 10% tri-tert-butylphosphine (2%, 15.5ml), dissolved in 200ml of toluene, reacted at 100°C for 3h, treated, washed with 200ml of water, the organic phase was passed through a silica gel column, and the eluent was decompressed Concentrate, boil and wash the solid with 100ml of ethanol and 100ml of petroleum ether, and filter to obtain 18.5g of the product with a yield of 85% and a molecular weight of 368.

Synthetic example 4

[0062] Synthesis Example 4: Synthesis of Intermediate M4

[0063]

[0064] M3 (36.8g, 100mmol), palladium acetate (0.23g, 1.0mmol), tricyclohexylphosphine tetrafluoroborate (1.11g, 3.0mmol) and DMF (700ml) were mixed, heated to 130 degrees for 3 hours , after the completion of the reaction, cool to room temperature, add 700 ml of pure water, extract with ethyl acetate, wash the organic phase with 300 ml of water, concentrate under reduced pressure and mix silica gel, cross a silica gel column (eluent: sherwood oil: ethyl acetate=2: 1) to obtain compound M4 (23.73 g, 82.4%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com