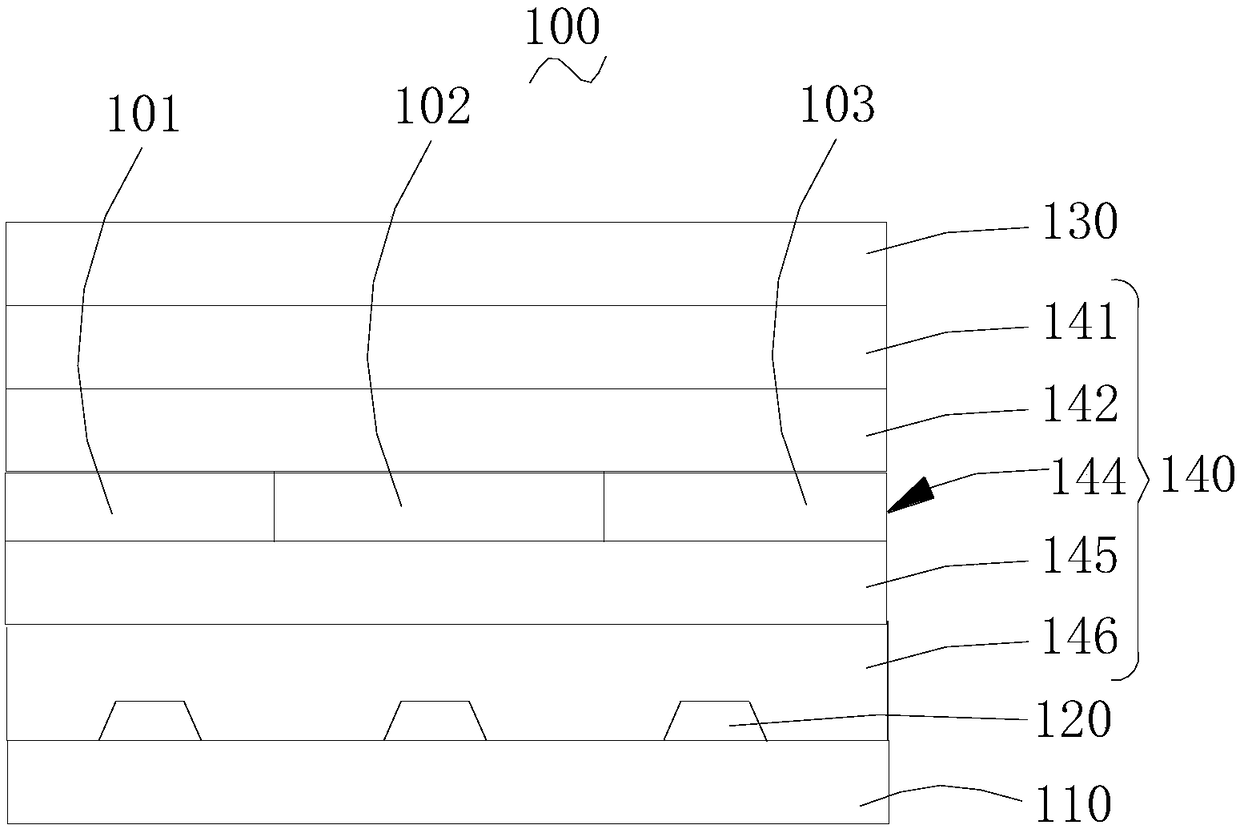

Organic light emitting device, fabrication method and display device

A technology of organic light-emitting devices and organic light-emitting layers, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electric solid-state devices, etc., can solve the problems of reducing luminous efficiency and unbalanced carriers in the red light layer, and achieve improved luminous efficiency , reduce complexity and cost, and reduce the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The invention also provides a preparation method of the organic light-emitting device.

[0089] A method for preparing an organic light-emitting device, comprising the steps of:

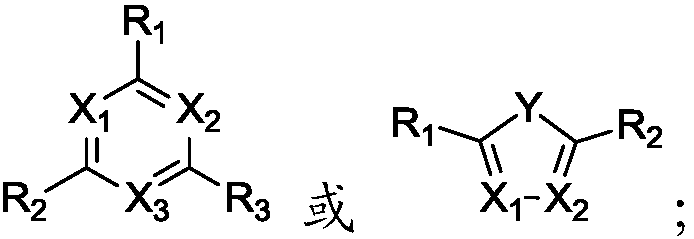

[0090] mixing the first host material with the second host material to form a host evaporation source;

[0091] Evaporating the host evaporation source and the guest evaporation source to form the red light layer;

[0092]Wherein, the first host material is an electron-biased host material, and the second host material is a hole-biased host material.

[0093] Other steps are all known to those skilled in the art, and will not be repeated here.

[0094] The above preparation method can obtain an organic light-emitting device with high luminous efficiency. In addition, the first host material and the second host material are mixed in advance to form the host material evaporation source. In this way, the number of evaporation sources can be reduced, thereby reducing the complexity and cost of...

Embodiment 1

[0100] The glass substrate was cleaned with detergent and deionized water, and dried under an infrared lamp, and a layer of anode material was sputtered on the glass substrate with a film thickness of 150 nm.

[0101] Then, place the glass substrate with the anode material in the vacuum chamber and evacuate to 1×10 -4 Pa, continue to vapor-deposit HATCN on the anode material film layer as a hole injection layer, the film forming rate is 0.1nm / s, and the vapor-deposited film thickness is 20nm. NPB was vapor-deposited on HATCN as a hole transport layer with a film formation rate of 0.1nm / s and a film thickness of 40nm.

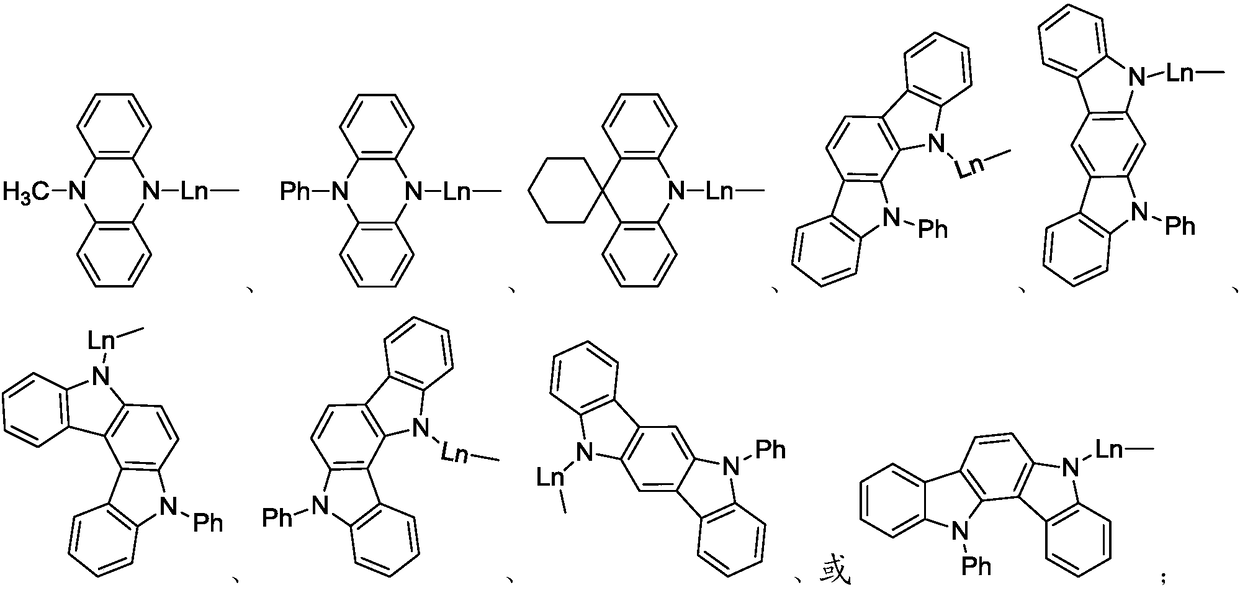

[0102] Evaporate the light-emitting layer on the hole transport layer, using the method of double-source co-evaporation, according to the mass percentage of the premixed host material (the first host material and the second host material are mixed in advance) and the phosphorescent dye through the film thickness monitor , adjust the film formation rate to contr...

Embodiment 2~ Embodiment 10

[0112] It is basically the same as Example 1, except that the specific structure of the organic light-emitting device is as follows:

[0113] ITO(150nm) / HATCN(20nm) / NPB(40nm) / premix host material: 1wt%Ir(piq-F) 2 (acac)(30nm) / TPBi(50nm) / 20%Ag:80%Mg(10nm) / Ag(15nm).

[0114] From Example 2 to Example 10, the ratio of the first host material H12 to the second host material H22 in the premixed host material is 1:9, 1:6, 1:3, 1:2, 1:1 respectively , 2:1, 3:1, 6:1, 9:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com