Self-calibration method of converter IGBT power module junction temperature measurement

A power module and converter technology, which is applied in the field of self-calibration of converter IGBT power module junction temperature measurement, can solve the problems of IGBT module safety performance impact, IGBT saturation voltage drop difficulty, device junction temperature calibration measurement, etc. The effect of reducing cost and technical difficulty, high sensitivity, and easy measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

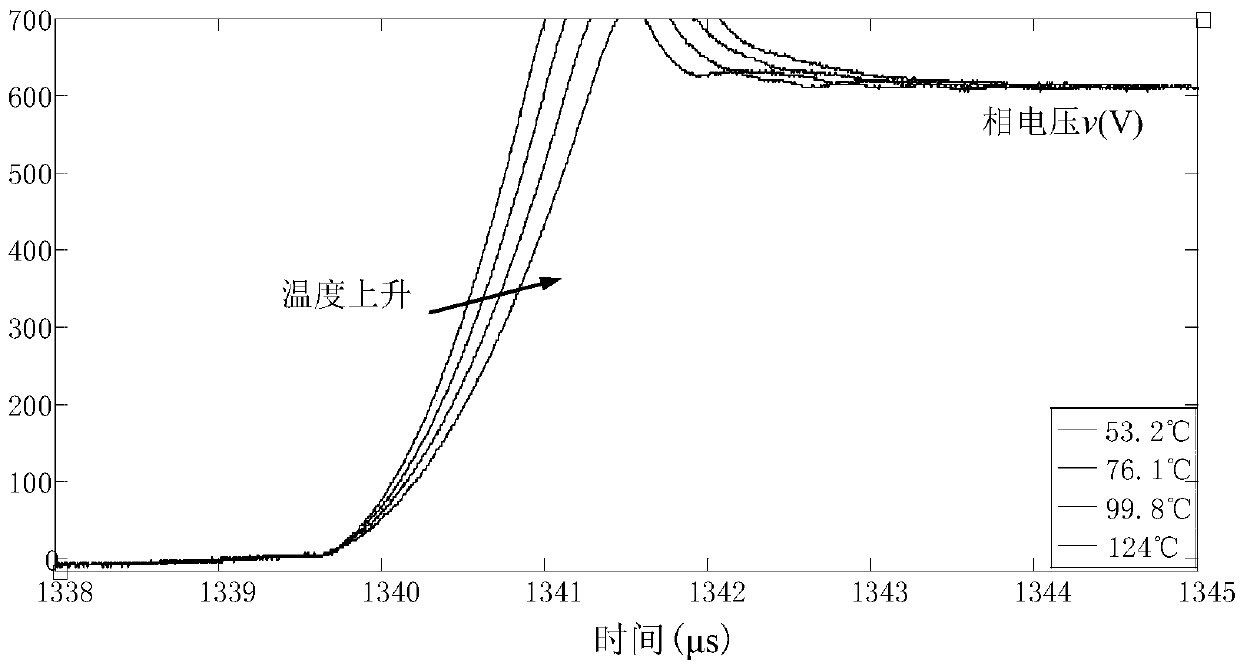

[0034] Detection object: IGBT device in power module FF50R12RT4

[0035] Self-calibration experiment process:

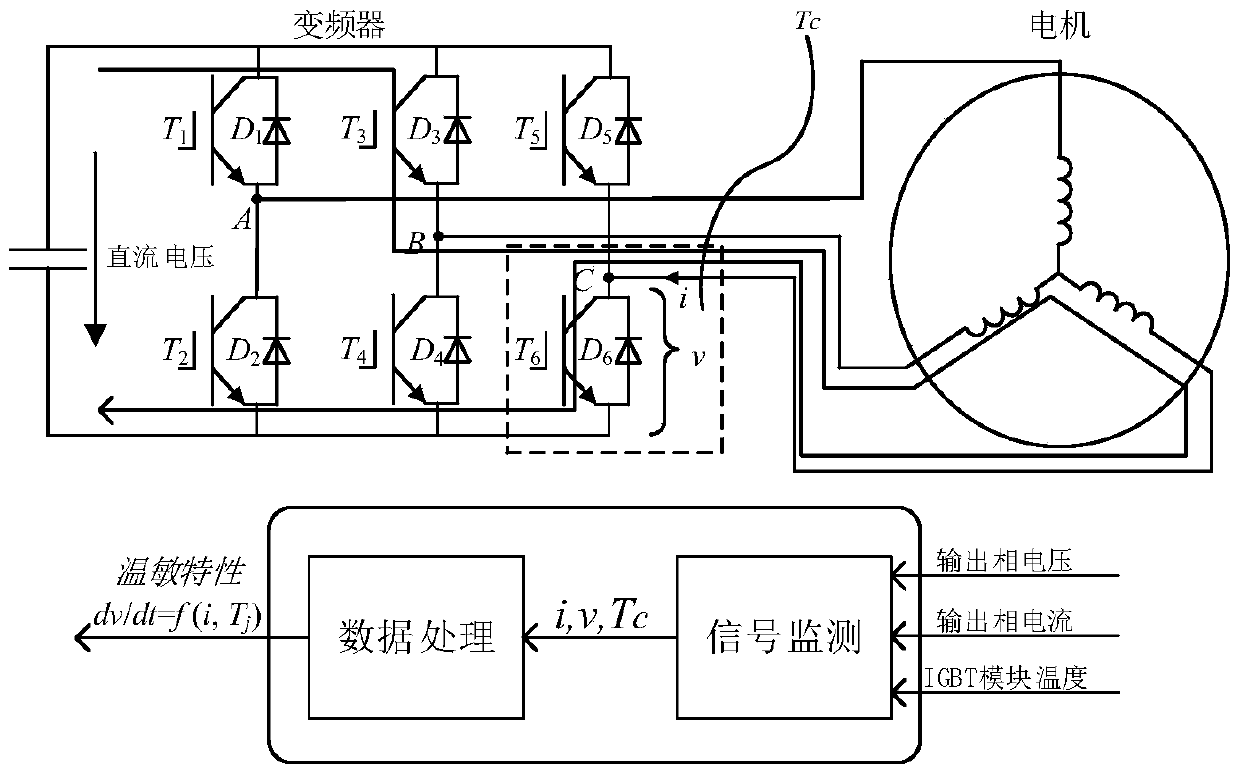

[0036] The self-calibration experimental system for measuring the junction temperature of the inverter IGBT module is as follows: figure 1 shown.

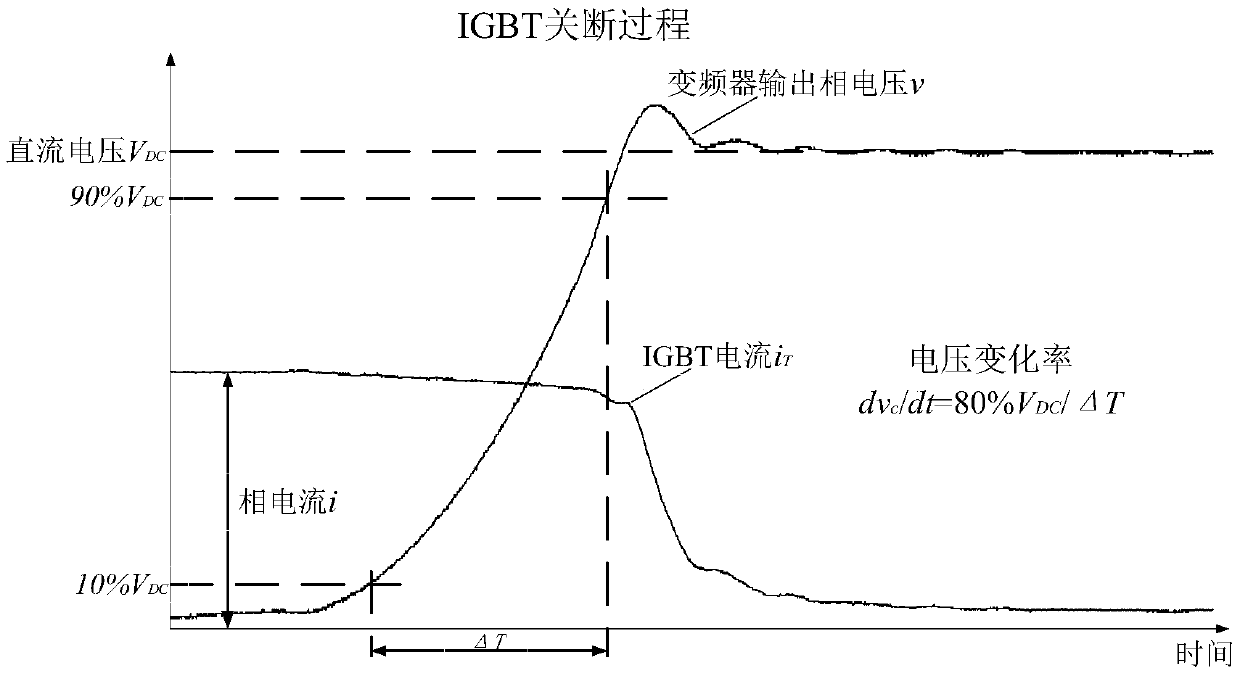

[0037] 1) Inverter self-heating: set the device under test as IGBTT 6 , the B and C phase half-bridges in the inverter and the motor windings form an H-bridge circuit, and by controlling the corresponding IGBT (T3 , T 4 , T 5 , T 6 ) gate trigger signal to generate a certain DC load current to heat the IGBT power module to make its temperature reach a specified value (such as 135°C). In order to ensure the safety of the inverter, the load DC current value should be lower than the rated current of the inverter. Keep it for a period of time (about 1s~10s), and when the internal heat balance of the power module is reached, the gate signal is blocked to cut off the load current, so that the inverter is in the cooling st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com