Bamboo-wound pipe and cast concrete integrated column for buildings and preparation method of bamboo-wound pipe and cast concrete integrated column for buildings

A technology of composite columns and winding pipes, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of poor connection quality of nodes, heavy formwork support workload, instability and damage of slender columns at 45 degrees, and improve construction efficiency. Efficiency, strong shear resistance, and the effect of avoiding natural erosion and instability damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

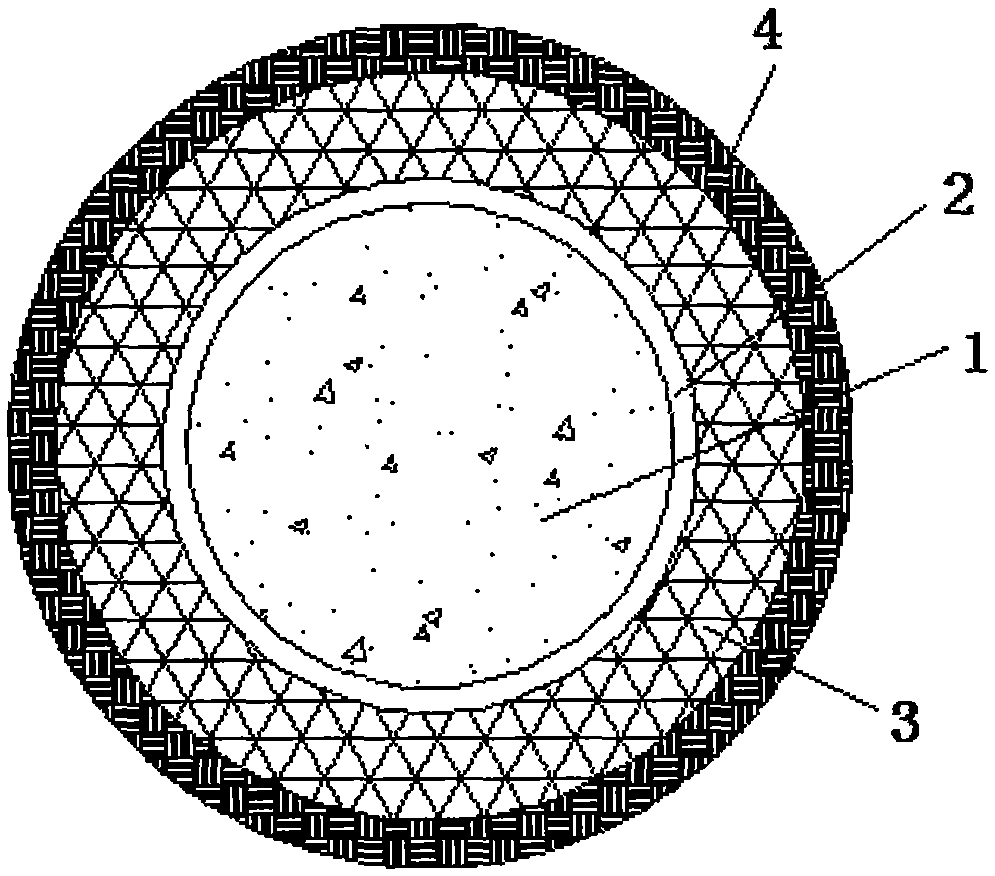

[0023] Such as figure 1 As shown, the embodiment of the present invention provides a concrete pouring composite column with bamboo winding pipes for construction, which sequentially includes a protective layer 4, a bamboo winding decoration structure 3, a middle bamboo and wood composite winding structure 2 and an internal concrete structure 1 from the outside to the inside. The bamboo winding decoration structure 3 is formed by winding the bamboo fiber belt and the lining grid belt uniformly and continuously through the resin glue in the form of ring and longitudinal plane winding, and the bamboo-wood composite winding structure 2 in the middle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com