A plugging agent for high-sulfur gas wells

A plugging agent, high-sulfur technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of salt corrosion resistance, damaged coiled tubing, poor rheological properties, etc., to improve corrosion ability , to meet the effect of water blocking requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

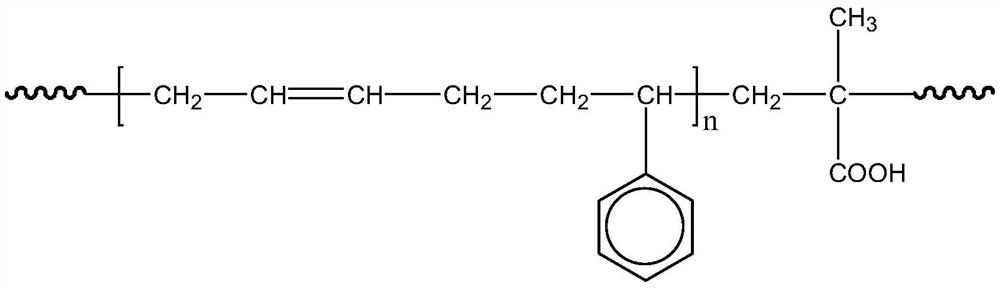

Method used

Image

Examples

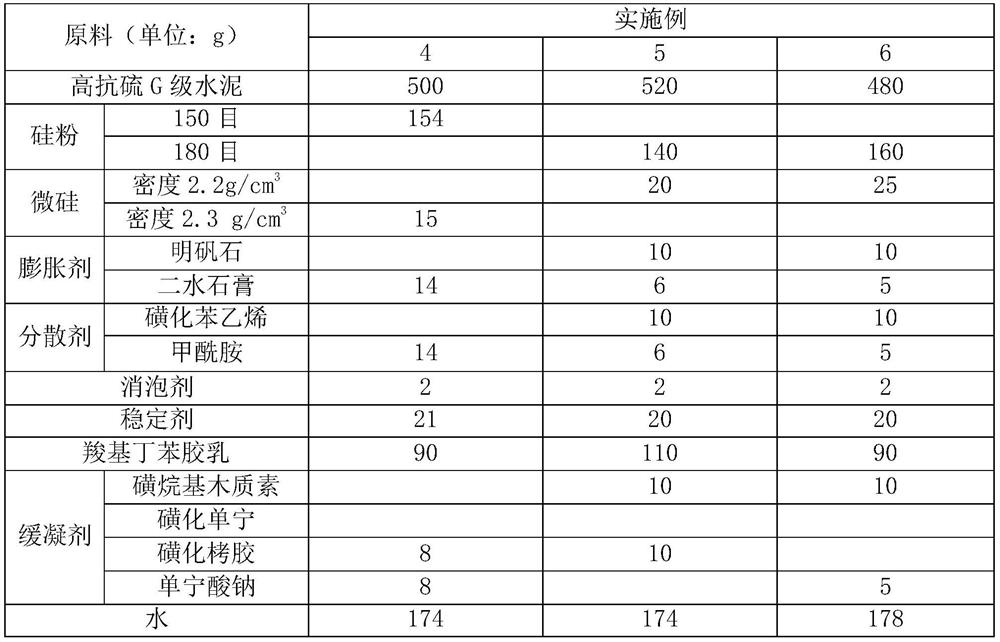

Embodiment 1

[0021] In a beaker, mix 500g of high sulfur-resistant G grade cement, 150g of 180 mesh silicon powder, and a density of 2.2g / cm 3 Mix 30g of microsilicon into dry powder, mix 176g of water, 10g of alunite, 21g of sulfonated styrene, 3g of defoamer, 15g of stabilizer, 80g of carboxylated styrene-butadiene latex, and 15g of sulfoalkyl lignin in a mixing container. Slowly pour the dry powder in the beaker into the mixing container, turn on the agitator in the mixing container, and rotate it at a speed of 12,000 rpm for 35 seconds to obtain the plugging agent for high-sulfur gas wells.

Embodiment 2

[0023] In a beaker, put 550g of high sulfur-resistant G-grade cement, 130g of 180-mesh silicon powder, and a density of 2.2g / cm 3 Mix 15g of micro-silicon into dry powder, mix 174g of water, 10g of alunite, 10g of sulfonated styrene, 1g of defoamer, 15g of stabilizer, 80g of carboxylated styrene-butadiene latex, and 5g of sulfoalkyl lignin in a mixing container. Slowly pour the dry powder in the beaker into the mixing container, turn on the agitator in the mixing container, and rotate it at a speed of 12,000 rpm for 35 seconds to obtain the plugging agent for high-sulfur gas wells.

Embodiment 3

[0025] In a beaker, mix 400g of high sulfur-resistant G-grade cement, 180g of 180-mesh silicon powder, and a density of 2.3g / cm 3 Mix 30g of microsilicon into dry powder, mix 181g of water, 12g of alunite, 10g of dihydrate gypsum, 12g of sulfonated styrene, 10g of formamide, 3g of defoamer, 30g of stabilizer, 110g of carboxylated styrene-butadiene latex, Mix 12g of sulfoalkyl lignin and 10g of sulfonated tannin evenly, slowly pour the dry powder in the beaker into the mixing container, turn on the stirrer in the mixing container, and rotate it at a speed of 12000 rpm for 35 seconds to obtain high Plugging agent for sour gas wells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com