A temperature-sensitive low fluid loss underground cross-linking plugging agent for sealing cracks and its application

An underground cross-linking and temperature-sensitive technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of different content, ratio and optimal ratio, performance to be further improved, and reduced matrix permeability. , to achieve good application value, good scour resistance, and the effect of reducing filtration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

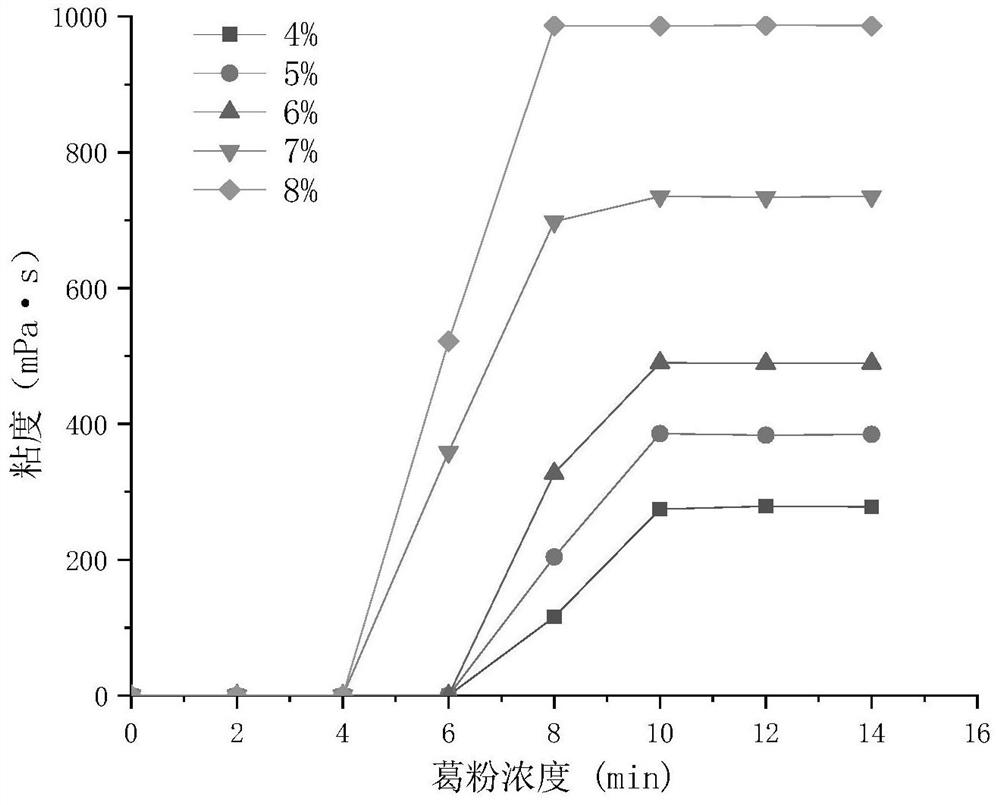

[0026] Take an appropriate amount of starch and add it to 100mL of water, stir well to disperse the starch evenly in the water to obtain a starch base liquid; And nano-silica was added into the aforementioned starch base liquid solution and stirred for 15 minutes at a speed of 400 r / min to obtain a reaction solution.

[0027] The present invention adopts the method of underground cross-linking, but due to the particularity of raw materials used in the present invention, it has corresponding advantages compared with conventional underground cross-linking and above-ground cross-linking methods.

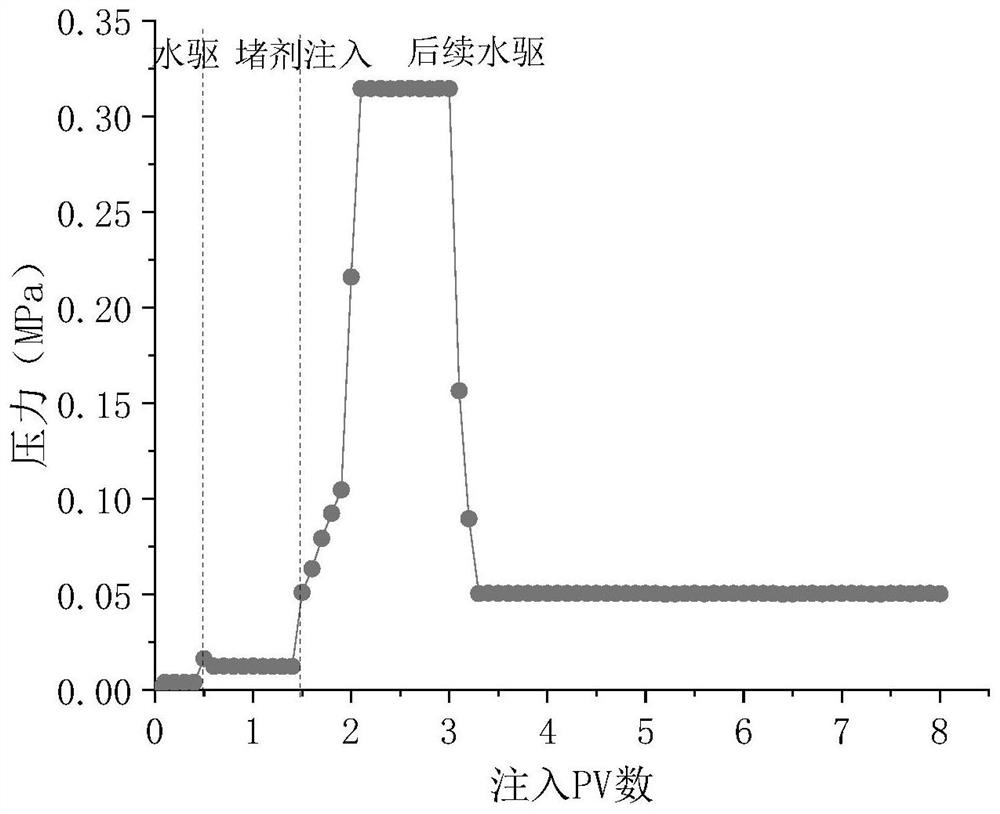

[0028] Compared with the conventional underground cross-linking plugging agent: because the starch will quickly gelatinize under suitable temperature conditions and the viscosity will increase rapidly, so its anti-fluid loss performance is better, and various reactive substances in the reaction liquid will not enter the matrix in large quantities At the same time, because of the differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com