Polyurethane resin, preparation method thereof and application thereof to micro cellular elastomer

A technology of polyurethane resin and polyetherester polyol, which is applied in the field of polyurethane resin and its preparation and application in microcellular elastomers, can solve the problem of poor hydrolysis resistance, reduced service life of polyurethane microcellular elastomers, and easy occurrence of Hydrolysis and other problems, to achieve the effect of improving molding hardness, high hardness, and improving porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

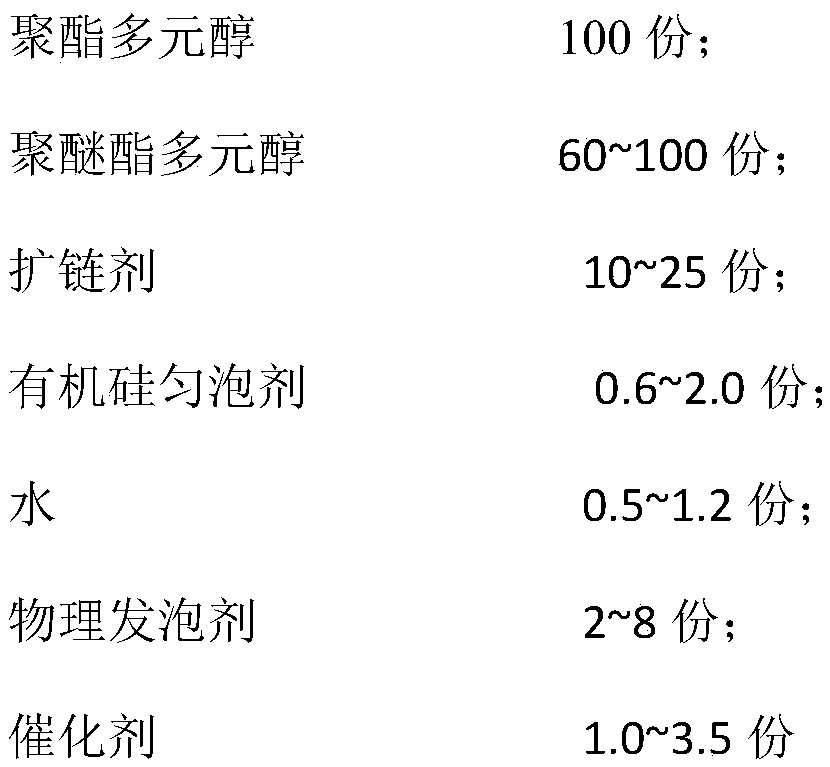

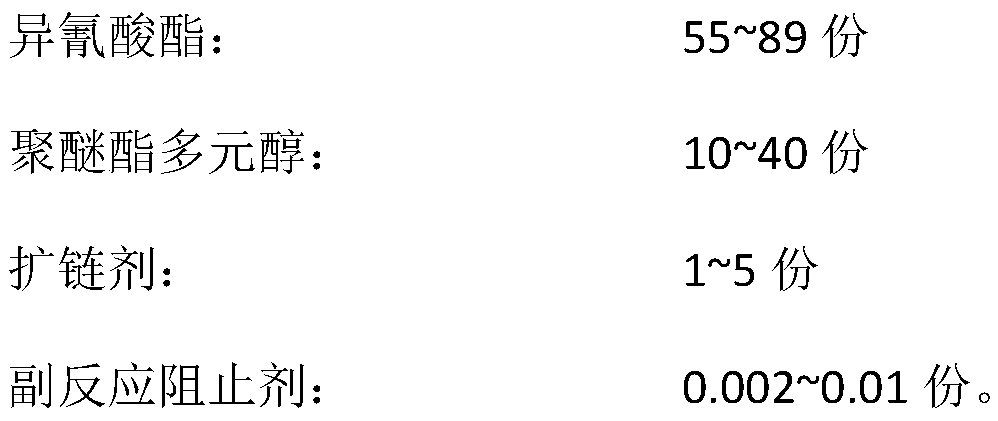

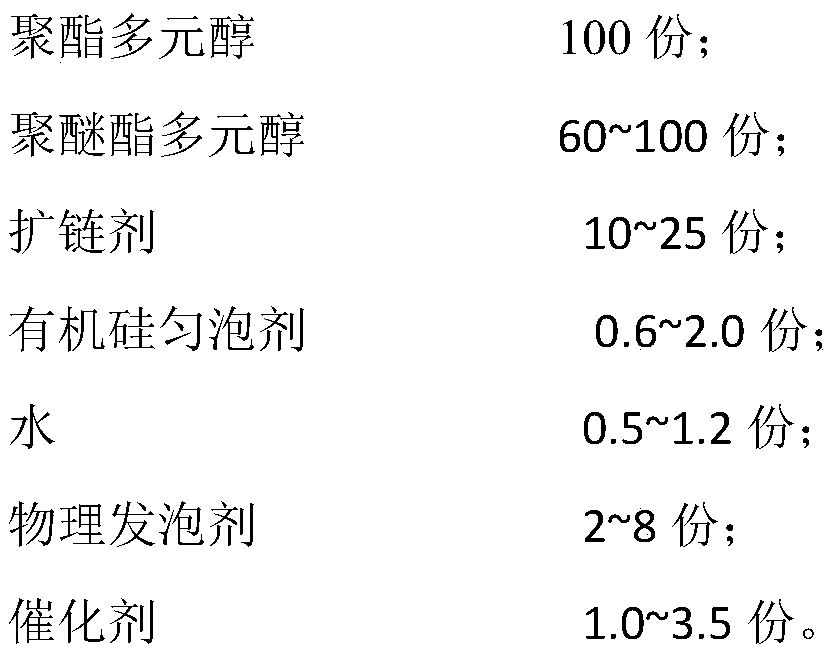

Method used

Image

Examples

Embodiment 1

[0039] (1) Crude production of polyether ester polyols: 70kg polyoxypropylene diols with a number average molecular weight of 700, 42.0kg phthalic anhydride, and 0.035 Kg double metal cyanide complex catalyst, start stirring and heat up to 120°C, then add 14.0kg of propylene oxide, undergo high-pressure 0.1MPa ring-opening polymerization for 4 hours, and vacuumize to remove unreacted propylene oxide after the reaction is completed , and lower the temperature to 75°C and put in 0.21kg NaOH, raise the temperature to 100°C, vacuumize and dehydrate for 3h, then add 30.0kg of ethylene oxide, react for 2h, after the reaction is completed, vacuumize and remove unreacted ethylene oxide to obtain crude Polyetherester polyol.

[0040] (2) Refining of polyether ester polyol: Take 100 kg of crude polyether ester polyol obtained in step (1), add 3.0 kg of deionized water, heat up to 60°C and stir for 1 hour, add 0.2 kg of phosphoric acid, stir for 1.5 hours, then add 1.0kg of magnesium he...

Embodiment 2

[0042] (1) Crude production of polyether ester polyols: 100 kg of polyoxypropylene diols with a number average molecular weight of 1000, 60 kg of phthalic anhydride, and 0.050 kg For the double metal cyanide complex catalyst, start stirring and heat up to 140°C, then add 90kg of propylene oxide, undergo a high-pressure 0.3MPa ring-opening polymerization reaction for 2 hours, vacuumize the unreacted propylene oxide after the reaction is completed, and Lower the temperature to 85°C and put in 1.0kg of basic catalyst, raise the temperature to 120°C, vacuumize and dehydrate for 1h, then add 60kg of ethylene oxide, and react for 1h, after the reaction is completed, vacuumize to remove unreacted ethylene oxide to obtain crude Polyetherester polyol.

[0043] (2) Refining of polyether ester polyol: take 100 kg of crude polyether ester polyol obtained in step (1), add 10.0 kg of deionized water, heat up to 70°C and stir for 0.5 h, then add 1.0 kg of phosphoric acid, and stir for 1.5 h ...

Embodiment 3

[0045](1) Crude production of polyether ester polyols: 100kg polyoxypropylene-oxyethylene glycol, 20kg phthalic anhydride with a number average molecular weight of 1000 and 20kg phthalic anhydride are added successively in a reaction kettle with a stirring and temperature control device, 0.040kg of double metal cyanide complex catalyst, start stirring and raise the temperature to 130°C, then add 75kg of propylene oxide, undergo a high-pressure 0.2MPa ring-opening polymerization reaction for 3 hours, and vacuumize the unreacted propylene oxide after the reaction is completed. And lower the temperature to 80°C and put in 0.40kg of basic catalyst, raise the temperature to 110°C, vacuumize and dehydrate for 2h, then add 20kg of ethylene oxide, react for 2h, after the reaction is completed, vacuumize to remove unreacted ethylene oxide to obtain Crude polyetherester polyol.

[0046] (2) Refining of polyether ester polyol: take 100 kg of crude polyether ester polyol obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com