18beta-glycyrrhetinic acid molecularly imprinted polymer with metal ions as bridging agent and monolithic column

A glycyrrhetic acid, molecular imprinting technology, applied in the direction of ion exchange, steroids, ion exchange regeneration, etc., can solve the problems of low selectivity, high price, unstable properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

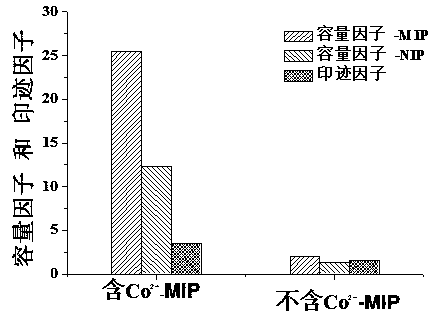

[0031] Preparation of molecularly imprinted monolithic columns using metal ions as bridging agents and 18β-glycyrrhetinic acid without metal ions as templates and comparison of their imprinting factors. Specific steps are as follows:

[0032] Preparation of 18β-glycyrrhetinic acid imprinted monolithic column by in situ polymerization:

[0033] a. The mass percent template 18β-glycyrrhetinic acid 3.09%, bridging agent cobalt acetate 1.64%, functional monomer 4-vinylpyridine 2.76%, initiator azobisisobutyronitrile 0.29%, crosslinking agent dimethacrylic acid Ethylene glycol ester 26.04%, dissolved in porogen 1-butyl-3-methylimidazolium tetrafluoroborate 43.59%, N,N-dimethylformamide 3.32%, dimethyl sulfoxide 19.27% In the mixed porogen solution; ultrasonically dissolved for 30min to dissolve and clarify, then pass nitrogen gas to remove the oxygen in the pre-polymerization mixture, and then inject the pre-polymerization mixture into a stainless steel column (100×4.6mmI.D.) , sea...

Embodiment 2

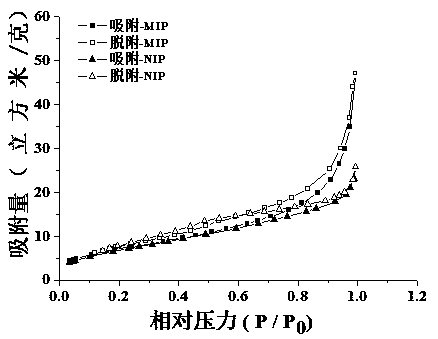

[0041] In order to characterize the morphological characteristics of 18β-glycyrrhetinic acid molecularly imprinted polymers with metal ions as bridging agents, 18β-glycyrrhetinic acid molecularly imprinted polymers MIP and 18β-glycyrrhetinic acid-free non-molecularly imprinted polymers NIP were prepared. And nitrogen adsorption-desorption analysis was carried out on the two polymers, the specific operation steps are as follows:

[0042] a. Preparation of polymer: dry the prepared polymer in the same way as above (Example 1), and grind it finely in a mortar.

[0043] b. Nitrogen adsorption test: put the ground 18β-glycyrrhetinic acid molecularly imprinted polymer MIP and 18β-glycyrrhetinic acid-free non-molecularly imprinted polymer NIP at 60oC for vacuum degassing (10 ?3 Torr) for 4 hours, take the dried particles and place them in the ASAP-2020 particle surface area and porosity analyzer, and process the obtained data to obtain the nitrogen adsorption-desorption isotherm and ...

Embodiment 3

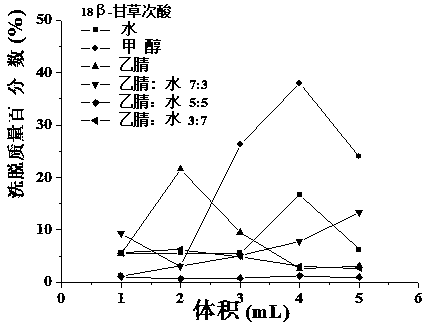

[0046] In the process of solid-phase extraction, the adsorption of the target compound must go through four steps: adsorbent activation, sample loading, rinsing, and elution, among which rinsing is the most important. The purpose of rinsing is to convert non-specific adsorption of target molecules into specific adsorption, while washing away impurities while retaining target molecules. The selection principle of the eluting solvent is to retain the target molecule and to elute the impurity molecule. The present invention screens the washing solvent, and the concrete steps are as follows:

[0047] a. Preparation of polymer: Dry the prepared polymer in the same way as above (Example 1), grind it finely in a mortar, and sieve (74 μm).

[0048] b. Washing process: Pack 1g of the polymer in step a into a 3mL solid-phase extraction column. After the SPE (SolidPhaseExtraction) column is activated and 2mg of the crude extract is loaded, the washing operation is performed. The elutin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com