Preparation method for nonmagnetic and high-strength texture nickel-based alloy composite baseband

A technology of composite base strip and nickel-based alloy, which is applied in the direction of metal rolling, etc., can solve the problems of expensive sintering equipment and maintenance costs, complex operation process, etc., and achieve the effects of low cost, elimination of casting stress, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step S100: Design and preparation of gating system

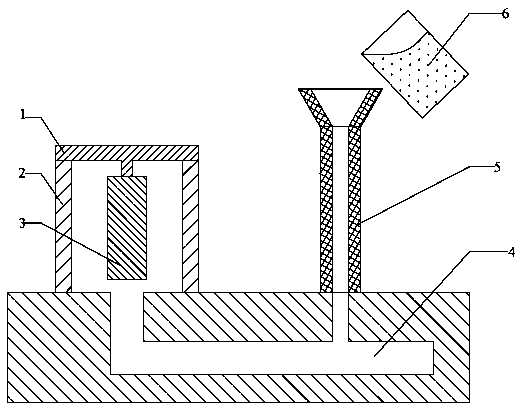

[0030] Step S101: Design a structure such as figure 1 Bottom pour gating system shown;

[0031] Step S102: The nickel-tungsten alloy obtained by vacuum induction melting with a tungsten atomic percentage of 9% is subjected to high-temperature forging and hot rolling to obtain a nickel-tungsten alloy billet, and the nickel-tungsten alloy billet is mechanically polished to remove scale, and the surface is cleaned After obtaining the core layer material 3, such as figure 1 the location shown;

[0032] Step S103: welding the core layer material 3 obtained in step S102 on the fixing bracket 1;

[0033] Step S104: cement the fixed bracket 1 obtained in step S103 on the mold 2;

[0034] Step S105: Cement the mold 2 obtained in step S104 on the refractory material with the runner 4 inside, and the funnel-shaped sprue cup designed at the upper end of the launder 5 helps the alloy liquid in the crucible to flow into the lau...

Embodiment 2

[0046] Step S100: Design and preparation of gating system

[0047] Step S101: Design a structure such as figure 1 Bottom pour gating system shown;

[0048] Step S102: The nickel-tungsten alloy obtained by vacuum induction melting with a tungsten atomic percentage of 10% is subjected to high-temperature forging and hot rolling to obtain a nickel-tungsten alloy billet, and the nickel-tungsten alloy billet is mechanically polished to remove scale, and the surface is cleaned After obtaining the core layer material 3, such as figure 1 the location shown;

[0049] Step S103: welding the core layer material 3 obtained in step S102 on the fixing bracket 1;

[0050] Step S104: cement the fixed bracket 1 obtained in step S103 on the mold 2;

[0051] Step S105: Cement the mold 2 obtained in step S104 on the refractory material with the runner 4 inside, and the funnel-shaped sprue cup designed at the upper end of the launder 5 helps the alloy liquid in the crucible to flow into the laun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com