A method and device for purifying volatile organic compounds by gas-phase photolysis-liquid-phase photocatalytic oxidation

A technology of photocatalytic oxidation of volatile organic compounds, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as catalyst efficiency decline, secondary pollution, deactivation, etc., to reduce production and accumulation, and purify efficiency High performance and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for purifying volatile organic compounds by gas-phase photolysis-liquid-phase photocatalytic oxidation, comprising the steps of:

[0043] S1. The experiment uses a UV lamp to decompose benzene, a volatile organic compound with a concentration of 15-50ppm, at a flow rate of 1L / min and a humidity of 50%, under the irradiation conditions of a UV lamp with a wavelength of 185nm for 0.5s, and the reaction produces ozone. The residual gas after photolysis forms a mixed gas;

[0044] S2. Pass the gas-phase photolyzed mixed gas into the liquid-phase photocatalytic spray tower, and the catalyst slurry TiO 2 (P25) From top to bottom, the mixed gas is from bottom to top, and the two are in reverse gas-liquid contact. Under the irradiation of a vacuum ultraviolet lamp, through the process of liquid phase absorption, ultraviolet photocatalytic oxidation, and ozone catalytic oxidation, VOCs are finally converted into CO 2 and H 2 O, discharged through the gas outlet, benze...

Embodiment 2

[0047] A method for purifying volatile organic compounds by gas-phase photolysis-liquid-phase photocatalytic oxidation, comprising the steps of:

[0048] S1. The experiment uses a UV lamp to decompose benzene, a volatile organic compound with a concentration of 15~50ppm, at a flow rate of 1L / min and a humidity of 50%, under the conditions of a vacuum UV lamp with a wavelength of 254nm for 0.8s, and the reaction generates ozone , to form a mixed gas with the residual gas after photolysis;

[0049] S2. Pass the gas-phase photolysis mixed gas into the liquid-phase photocatalytic spray tower, and the catalyst slurry is TiO modified by Mn 2 (P25) (Mn loadings are 0.1%, 1%, 3% and 5% respectively), the catalyst slurry is from top to bottom, the mixed gas is from bottom to top, the two are in reverse gas-liquid contact, under the irradiation of vacuum ultraviolet lamp After liquid phase absorption, ultraviolet photocatalytic oxidation, and ozone catalytic oxidation, VOCs are finally...

Embodiment 3

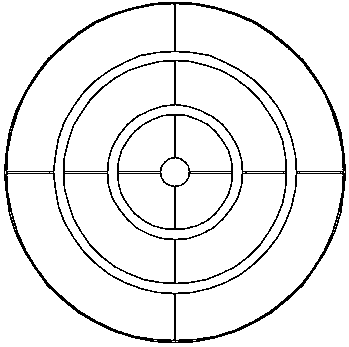

[0052] The present embodiment provides a gas phase photolysis-liquid phase photocatalysis device based on the above method, such as Figure 1~3 As shown, it includes a gas phase photolysis chamber 3, a liquid phase photocatalytic spray tower 1 and a liquid recovery regeneration box 15, and the liquid phase photocatalytic spray tower 1 is sequentially provided with an exhaust gas intake device 13, a filter Ball layer 11, absorption liquid spray device 9, mist eliminator 12 and gas discharge port 14, the lower part of the liquid phase photocatalytic spray tower 1 is connected with the upper part of the liquid recovery regeneration box 15, and the liquid recovery regeneration box 15 It is connected with the absorption liquid spraying device 9 through the liquid delivery pipeline 5 and the circulating pump 2 . The absorption liquid spraying device 9 includes several solution branch pipes, and the solution branch pipes are all communicated with the liquid delivery pipeline 5, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com