Medicine composition sustained release micro-sphere preparation for treating osteoporosis and preparing method thereof

A slow-release microsphere preparation and technology of slow-release microspheres, which are applied in drug combination, drug delivery, pharmaceutical formulation, etc., can solve problems such as no corresponding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

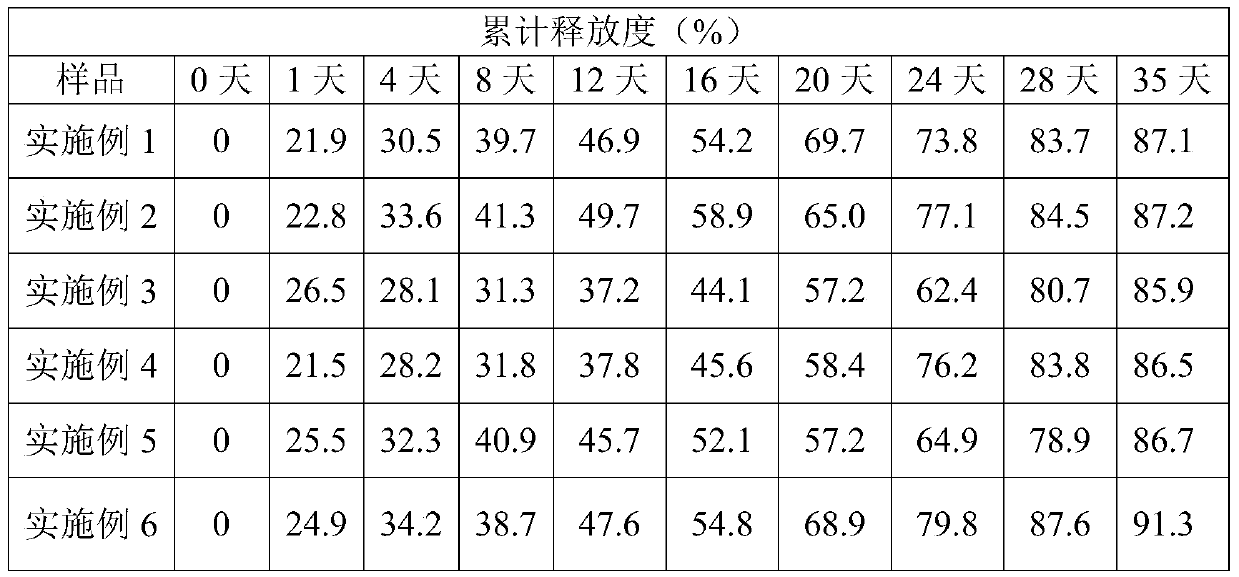

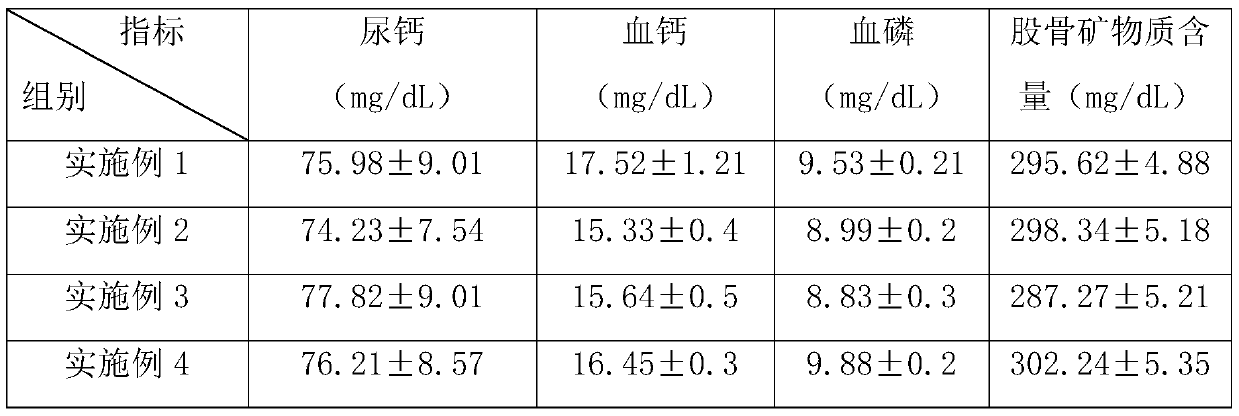

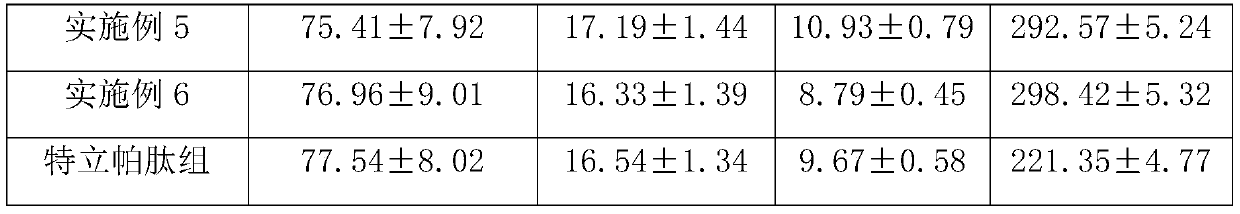

Examples

Embodiment 1

[0013] Weigh 20 μg teriparatide, 10 mg alendronate, 5 mg gelatin, 5 mg glycerin, 10 ml 0.5% polyvinyl alcohol solution and dissolve them in distilled water to obtain the inner aqueous phase; weigh 400 mg polylactide and dissolve them in dichloromethane In methane, an oily phase was obtained. First move the water phase into the oil phase, put it on an emulsification disperser at room temperature at a speed of 30000rpm, and emulsify it for 30 seconds, then transfer the obtained W / O emulsion into an aqueous solution of polyvinyl alcohol, place it on an emulsification disperser at a speed of 5000rpm Rotating speed, homogenize the milk for 2 minutes to obtain W / O / W type double emulsion, stir at a low speed of 500rpm at room temperature for 2.5 hours, remove the organic solvent, ultracentrifuge, collect the obtained microspheres, wash with distilled water several times, and then centrifuge again , adding 45 mg of sorbitol, and freeze-drying to obtain sustained-release microspheres o...

Embodiment 2

[0016] Weigh 40 μg teriparatide, 1 mg alendronate, 0.5 mg gelatin, 0.5 mg glycerin, 5 ml 0.5% polyvinyl alcohol solution, dissolve in distilled water to obtain the inner aqueous phase; weigh 10 mg polyglycolide solution In dichloromethane, an oily phase was obtained. First move the water phase into the oil phase, put it on an emulsification disperser at room temperature at a speed of 30000rpm, and emulsify it for 30 seconds, then transfer the obtained W / O emulsion into an aqueous solution of polyvinyl alcohol, place it on an emulsification disperser at a speed of 5000rpm Rotating speed, homogenize the milk for 2 minutes to obtain W / O / W type double emulsion, stir at a low speed of 500rpm at room temperature for 2.5 hours, remove the organic solvent, ultracentrifuge, collect the obtained microspheres, wash with distilled water several times, and then centrifuge again , adding 1.5 mg of mannitol, and freeze-drying to obtain sustained-release microspheres of the pharmaceutical com...

Embodiment 3

[0019] Weigh 10mg teriparatide, 200000IU salmon calcitonin, 30mg gelatin, 30mg glycerin, 20ml0.5% polyvinyl alcohol solution, dissolve in distilled water to obtain the inner water phase; weigh 500mg polylactide-glycolide solution In dichloromethane, an oily phase was obtained. First move the water phase into the oil phase, put it on an emulsification disperser at room temperature at a speed of 30000rpm, and emulsify it for 30 seconds, then transfer the obtained W / O emulsion into an aqueous solution of polyvinyl alcohol, place it on an emulsification disperser at a speed of 5000rpm Rotating speed, homogenize the milk for 2 minutes to obtain W / O / W type double emulsion, stir at a low speed of 500rpm at room temperature for 2.5 hours, remove the organic solvent, ultracentrifuge, collect the obtained microspheres, wash with distilled water several times, and then centrifuge again , adding 30 mg of mannitol, and freeze-drying to obtain sustained-release microspheres of the pharmaceu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com