A compact circular waveguide tm01‑te01 mode converter

A mode converter and circular waveguide technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of input and output not on the same axis, large size, complex structure, etc., and achieve suppression of asymmetrical modes, light weight, The effect of shortening the spatial distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

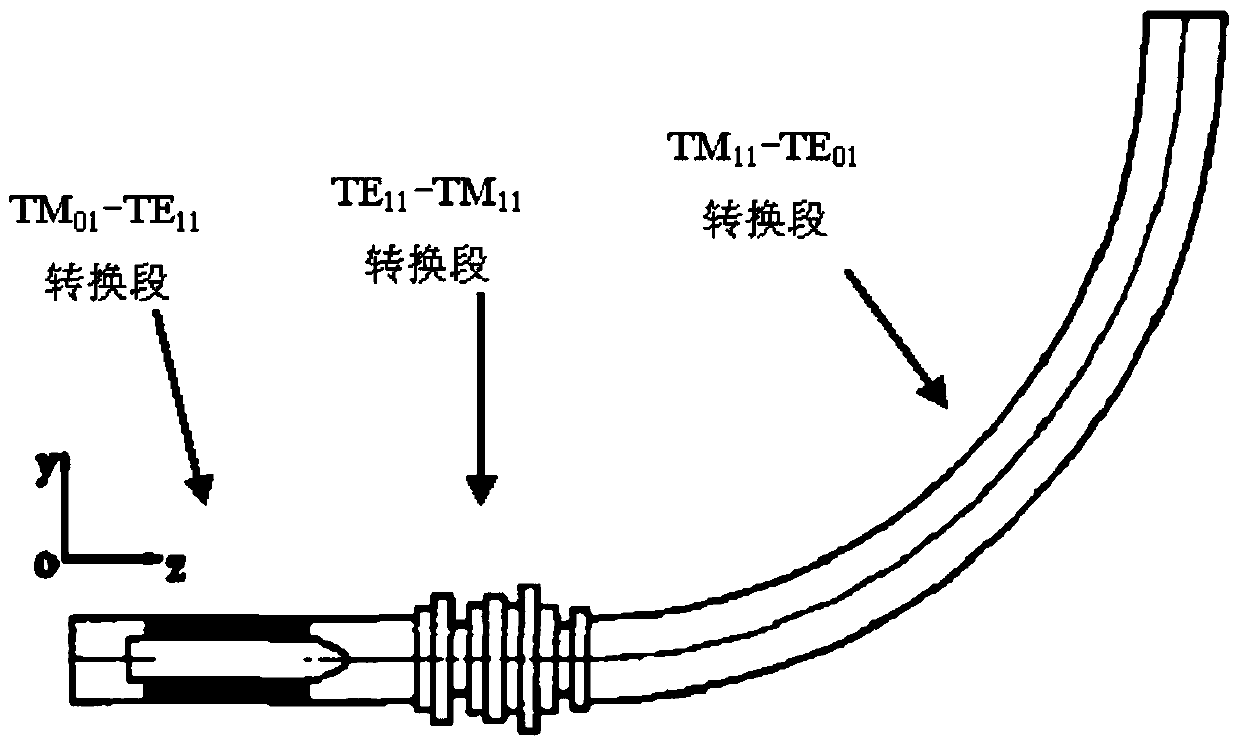

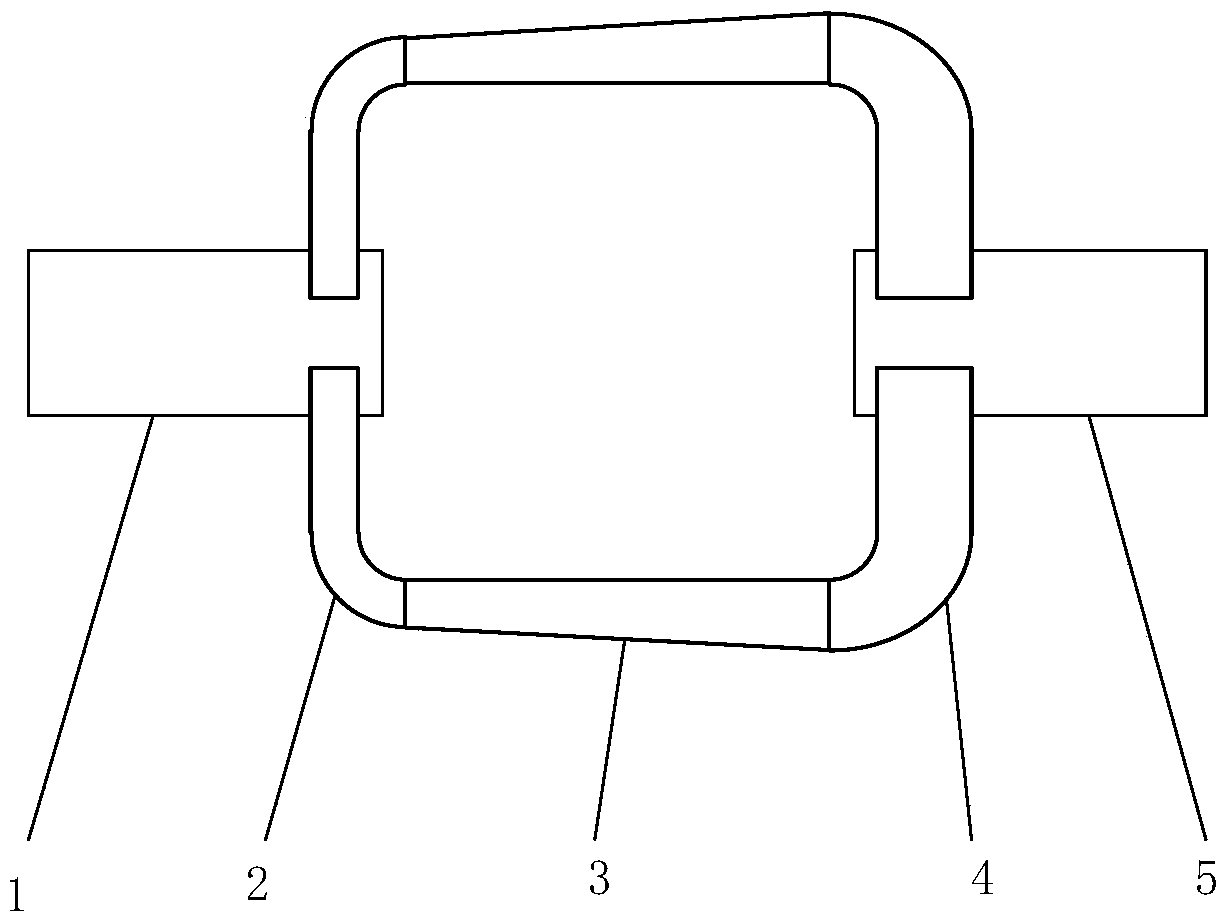

[0017] The circular waveguide TM01-TE01 mode converter of the present invention has a structure as follows figure 1 As shown, it mainly includes input circular waveguide 1, output circular waveguide 5 and various rectangular waveguide components connected between them. Firstly, the radius dimensions of the input circular waveguide 1 and the output circular waveguide 5 are selected to ensure that the TM02 mode and higher order modes are cut-off modes at the operating frequency. The left end of the input circular waveguide 1 is used to feed microwave energy whose mode is TM01 mode, and the right end of the input circular waveguide 1 is short-circuited. Preferably, in this embodiment, six identical rectangular E-plane 90-degree curved waveguides 2 are coupled and connected to the input circular waveguide 1 at equal intervals in the circumferential direction along the side of the input circular waveguide 1 with a certain distance from the short-circuit surface. At the coupling po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com