Preparation method of oxide porous material

A technology of porous materials and oxides, which is applied in the field of preparation of oxide porous materials, can solve the complex process of colloidal crystal templates, the difficulty of large-scale control of the properties of the target material, such as pore size, porosity and wall thickness, and difficulty in large-scale production and other problems to achieve the effect of avoiding the instability of the overall structure, improving stability and functionality, and suitable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

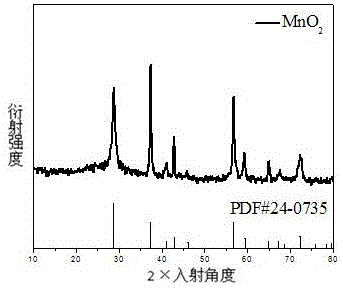

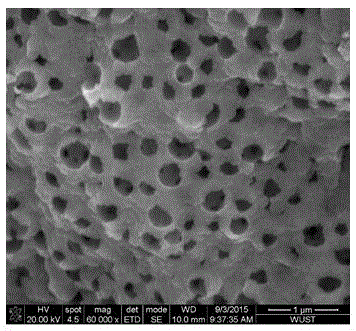

[0026] A preparation method of manganese dioxide porous material. The preparation method is:

[0027] 1) Dissolve manganese nitrate tetrahydrate in tert-butanol at a concentration of 5 to 6.5 mol / L, stir for 3 to 5 hours to obtain solution I.

[0028] 2) According to the mass ratio of manganese nitrate tetrahydrate and ethyl cellulose of 1: (0.01~0.04), add ethyl cellulose to solution I and stir for 1 to 2 hours to obtain solution II.

[0029] 3) According to the mass ratio of manganese nitrate tetrahydrate to silicon dioxide of 1:(0.25~0.35), add silicon dioxide to solution II and stir for 3~5 hours to obtain solution III.

[0030] 4) The solution III is subjected to liquid nitrogen freezing treatment, and then dried in a vacuum freeze dryer for 48 to 72 hours to obtain a dried product.

[0031] 5) Put the dried product in a tube furnace, heat it up to 300~500℃ at a rate of 4~5℃ / min in an argon atmosphere or air atmosphere, keep it for 4~7h, and cool down naturally with the furnace to...

Embodiment 2

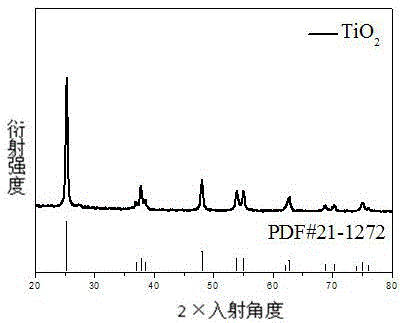

[0034] A preparation method of titanium dioxide porous material. The preparation method is:

[0035] 1) According to the concentration of 6.5~8.0mol / L, dissolve titanium sulfate in tert-butanol and stir for 3~5 hours to obtain solution I.

[0036] 2) According to the mass ratio of titanium sulfate to polyvinylpyrrolidone of 1:(0.04~0.07), add polyvinylpyrrolidone to solution I and stir for 1~2 hours to obtain solution II.

[0037] 3) According to the mass ratio of titanium sulfate to polymethyl methacrylate of 1: (0.15-0.25), add polymethyl methacrylate to solution II, stir for 3 to 5 hours to obtain solution III.

[0038] 4) The solution III is subjected to liquid nitrogen freezing treatment, and then dried in a vacuum freeze dryer for 48 to 72 hours to obtain a dried product;

[0039] 5) Put the dried product in a tube furnace, heat it up to 500~700℃ at a rate of 4~5℃ / min in an argon atmosphere or air atmosphere, keep it for 7~10h, cool naturally with the furnace, and remove the temp...

Embodiment 3

[0042] A preparation method of lithium titanate porous material. The preparation method is:

[0043] 1) According to the concentration of each substance of 8.0~10.0mol / L, dissolve tetrabutyl titanate and lithium acetate dihydrate in an organic solvent successively, and stir for 3~5 hours to obtain solution I.

[0044] The organic solvent is a mixed solvent of ethanol and glacial acetic acid, and the volume ratio of ethanol and glacial acetic acid in the mixed solvent is 1:1.

[0045] 2) According to the mass ratio of the mixed salt of tetrabutyl titanate and lithium acetate dihydrate to ethyl cellulose is 1: (0.07~0.10), add ethyl cellulose to solution I and stir for 1 to 2 hours to obtain Solution II.

[0046] 3) According to the mass ratio of the mixed salt of tetrabutyl titanate and lithium acetate dihydrate to polystyrene of 1:(0.10~0.15), add polystyrene to solution II and stir for 3~5 hours to obtain solution III .

[0047] 4) The solution III is subjected to liquid nitrogen fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com