Continuous fiber-reinforced thermoplastic resin prepreg and preparation method thereof

A technology of reinforced thermoplastic and continuous fiber, applied in the direction of chemical instruments and methods, layered products, lamination devices, etc., to achieve the effect of small fiber damage, ensure stability, and avoid thermal and oxygen aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

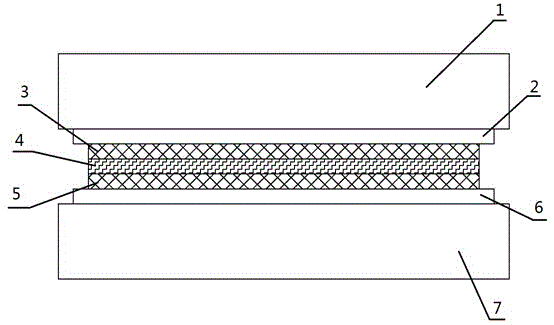

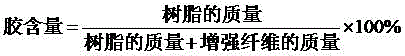

[0081] The selected density is 0.949g / cm 3 , a high-density polyethylene resin film matrix with a thickness of 0.0458mm, electronic grade glass fiber cloth 7628 as a continuous reinforcement material, and a control glue content of 30%. Cut the fiber cloth and resin film into a square of 400*400mm, and blow the fiber cloth and resin film with hot air at a temperature of about 120°C to remove impurities and achieve the purpose of drying. Store the treated material in an oven at 105°C to prevent moisture regain. Use two plastic films to sandwich a layer of electronic grade glass fiber cloth 7628, according to figure 1 The method shown is placed in a press. The pre-set temperature of the press is 210°C. After the material is put into the press, close the safety door and start the program. The pressing program is 210°C, the pressure is 1.5MPa and the pressure is 180s, and the pressure is kept at 1.5MPa. The water cooling system that comes with the press is used to cool down. Mo...

Embodiment 2

[0083] The selected density is 0.851g / cm 3 , a polypropylene resin film matrix with a thickness of 0.051mm, electronic grade glass fiber cloth 7628 as a continuous reinforcement material, and the glue content is controlled at 30%. Cut the fiber cloth and resin film into a square of 400*400mm, rinse the fiber cloth and resin film with low boiling point solvents such as acetone, methanol, ethanol, etc. Dry in oven. Use two plastic films to sandwich a layer of electronic grade glass fiber cloth 7628, according to figure 1 The method shown is placed in a press. The pre-set temperature of the press is 230°C. After the material is put into the press, close the safety door and start the program. The pressing program is 230°C, the pressure is 0.4MPa for 60s, continue to increase the pressure to 0.8MPa and press for 60s, keep the pressure at 0.8MPa, and use the water cooling system that comes with the press to cool down. The cooling rate is controlled at 10-15°C / min. When the tempe...

Embodiment 3

[0085] The selected density is 1.34g / cm 3 , a polyphenylene sulfide resin film matrix with a thickness of 0.051mm, and unidirectional carbon fiber cloth as a continuous reinforcement material, and the control glue content is 40%. Cut the fiber cloth and resin film into a square of 400*400mm, rinse the fiber cloth and resin film with low boiling point solvents such as acetone, methanol, ethanol, etc. Dry in oven. Use two plastic films to sandwich a layer of unidirectional carbon fiber cloth, according to figure 1 The method shown is placed in a press. The pre-set temperature of the press is 320°C. After the material is put into the press, close the safety door and start the program. The pressing program is 320°C, the pressure is 0.4MPa, press for 60s, then raise the temperature to 330°C, increase the pressure to 0.8MPa and press for 60s, keep the pressure at 0.8MPa, use the water cooling system that comes with the press to cool down, and the cooling rate is controlled at 5-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com