Tailor-welding molding method for foamed aluminum sandwiched components

A foamed aluminum and sandwich technology, applied in the field of aluminum plate welding, can solve the problems of low metallurgical bonding strength of the plate/core interface, poor compactness and uniformity of the preform, and achieve high density and uniformity, reduce production costs, and improve The effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

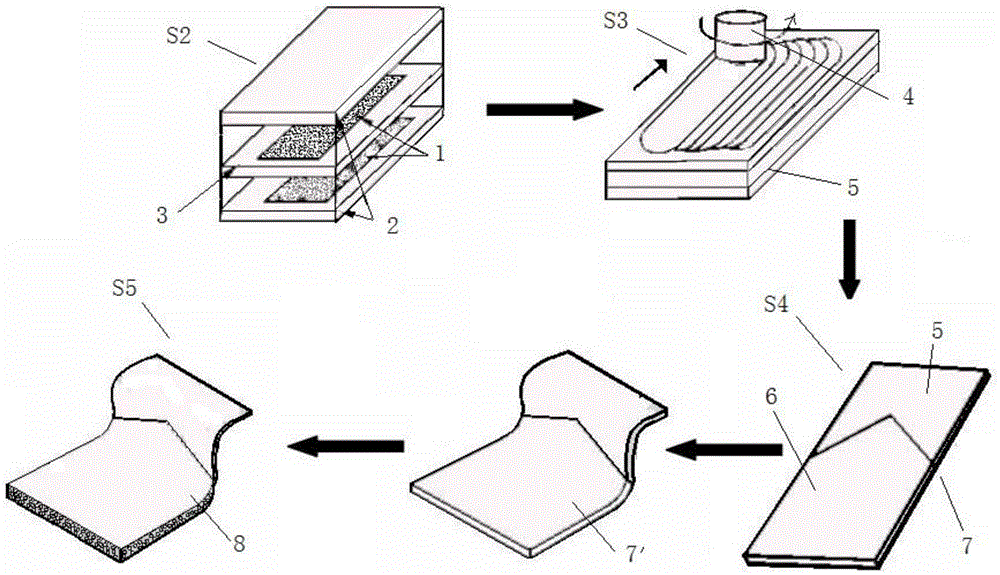

[0048] The present invention comprises the following steps:

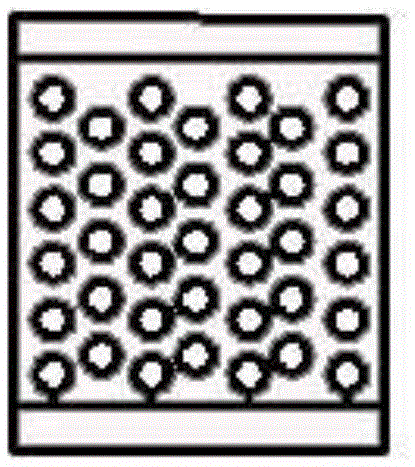

[0049] S1. Fully mix the foaming agent and stabilizer powder: the foaming agent is titanium hydride, the powder size is 50 μm, and the mass ratio of the added amount to the two metal plates is 1%; the stabilizer is aluminum oxide powder, the powder size is 1 μm, The mass ratio of the amount added to the two metal plates is 10%;

[0050] S2, the above mixed powder is evenly distributed on the lower 304 stainless steel plate and the ADC06 middle layer aluminum alloy plate, the plate thickness of the ADC06 middle layer aluminum alloy plate is 2mm, the upper layer 304 stainless steel plate is covered, and the thickness of the upper and lower 304 stainless steel plate is 1mm, the size of the three plates is the same, the length is 200mm, and the width is 300mm;

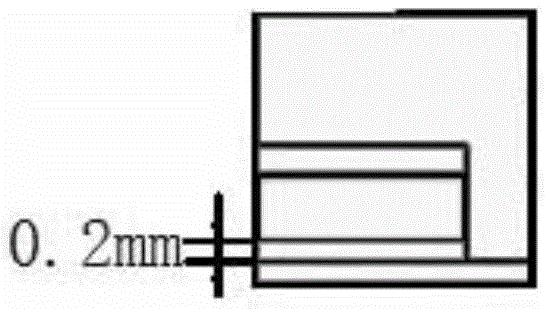

[0051] S3. Install the above-mentioned slab on the working platform of the friction stir welding equipment, and then carry out 8 times of friction stir welding...

Embodiment 2

[0055] The present invention comprises the following steps:

[0056] S1. Fully mix the foaming agent and stabilizer powder: the foaming agent is titanium hydride, the powder size is 50 μm, and the mass ratio of the added amount to the metal plate is 1%; the stabilizer is alumina powder, the powder size is 1 μm, and the added amount The mass ratio to the sheet metal is 10%;

[0057] S2, the above mixed powder is evenly distributed on the lower 6061 aluminum alloy sheet (thickness 1mm) and the ADC06 middle layer aluminum alloy sheet (thickness 2mm); cover the upper layer 6061 aluminum alloy sheet (thickness 1mm), three sheets The size is the same, the length is 200mm, and the width is 300mm;

[0058] S3. Install the above-mentioned slab on the working platform of the friction stir welding equipment, and then carry out 8 times of friction stir welding. The welding process parameters are welding speed 200r / min, welding speed 600mm / min, axial downward pressure 0.1mm, after weldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com