Nutritional-type instant compound fruit and vegetable paper and preparation method thereof

A fruit and vegetable paper and nutritional technology, which is applied in the field of nutritional ready-to-eat composite fruit and vegetable paper and its preparation, can solve the problems of difficulty in meeting the toughness requirements of fruit and vegetable paper, loss of nutrients, loss of fresh taste of fruits and vegetables such as cucumber, etc., and achieves excellent bonding effect. , reduce the loss of nutrients, the effect of crisp taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

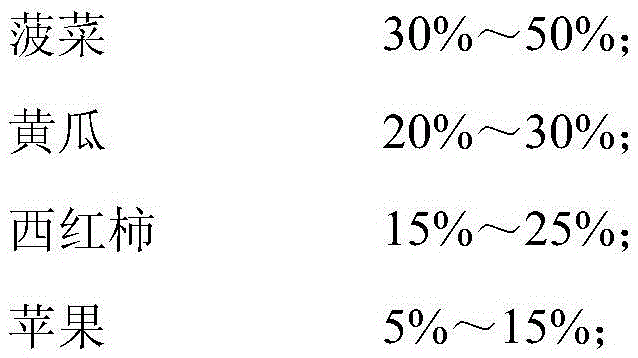

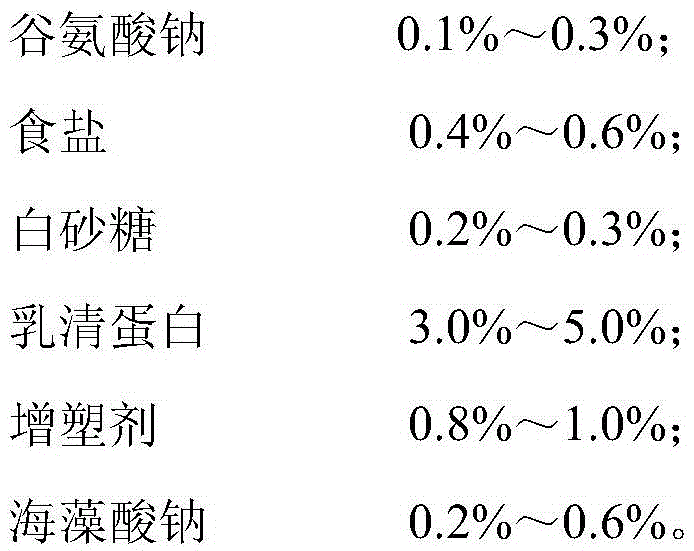

[0033] Weigh raw materials: 30 kg of spinach, 24 kg of cucumber, 25 kg of tomato, 14 kg of apple; the seasonings and binders included: 0.1 kg of sodium glutamate, 0.4 kg of salt, 0.3 kg of white sugar, 5.0 kg of whey protein , 0.8 kg of glycerin, 0.4 kg of sodium alginate.

[0034] The preparation method of composite fruit and vegetable powder comprises the following steps:

[0035] (1) Selection of raw materials

[0036] Raw materials are required to be fresh, mature, free from rot, insects, and pesticide residues, with good color and not too tender or too old;

[0037] (2) Cleaning and cutting

[0038] Wash the raw materials with running water to remove sediment, impurities and pesticide residues; cut the washed spinach into 2cm-4cm sections, and cut cucumbers, tomatoes and apples into pieces of 2×2×2cm-4×4×4cm;

[0039] (3) Color protection

[0040] Spinach and tomato were blanched with 0.1wt% sodium sulfite solution at 80°C to protect the color. The blanching time was ...

Embodiment 2

[0055] Weigh raw materials: 45 kg of spinach, 25 kg of cucumber, 15 kg of tomato, 8 kg of apple; the seasonings and binders included: 0.2 kg of sodium glutamate, 0.6 kg of salt, 0.3 kg of white sugar, 4.8 kg of whey protein , mannitol 0.9 kg, sodium alginate 0.2 kg.

[0056] The preparation method of composite fruit and vegetable powder comprises the following steps:

[0057] (1) Selection of raw materials

[0058] Raw materials are required to be fresh, mature, free from rot, insects, and pesticide residues, with good color and not too tender or too old;

[0059] (2) Cleaning and cutting

[0060] Wash the raw materials with running water to remove sediment, impurities and pesticide residues; cut the washed spinach into 2cm~4cm sections, and cut cucumbers, tomatoes and apples into 2×2×2cm~4×4×4cm blocks;

[0061] (3) Color protection

[0062] Spinach and tomato were blanched with 0.3wt% sodium sulfite solution at 95°C to protect the color, and the blanching time was 1min. Af...

Embodiment 3

[0078] Weigh raw materials: 40 kg of spinach, 20 kg of cucumber, 22 kg of tomato, 12.4 kg of apple; the seasonings and binders included are: 0.3 kg of sodium glutamate, 0.5 kg of table salt, 0.2 kg of white sugar, and 3 kg of whey protein , glycerin 1.0 kg, sodium alginate 0.6 kg.

[0079] The preparation method of composite fruit and vegetable powder comprises the following steps:

[0080] (1) Selection of raw materials

[0081] Raw materials are required to be fresh, mature, free from rot, insects, and pesticide residues, with good color and not too tender or too old;

[0082] (2) Cleaning and cutting

[0083] Wash the raw materials with running water to remove sediment, impurities and pesticide residues; cut the washed spinach into 2cm~4cm sections, and cut cucumbers, tomatoes and apples into 2×2×2cm~4×4×4cm blocks;

[0084] (3) Color protection

[0085] Spinach and tomato were blanched with 0.2wt% sodium sulfite solution at 90°C to protect the color. The blanching time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com