An intelligent profiling ditch clearing device for a furrow machine and its control method

An intelligent and ditch-clearing technology, applied in the field of agricultural machinery, can solve problems such as reducing operation efficiency, inconsistency, and increasing manufacturing costs, and achieves the effect of improving uniformity, facilitating suppression, and maintaining smoothness in the ditch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

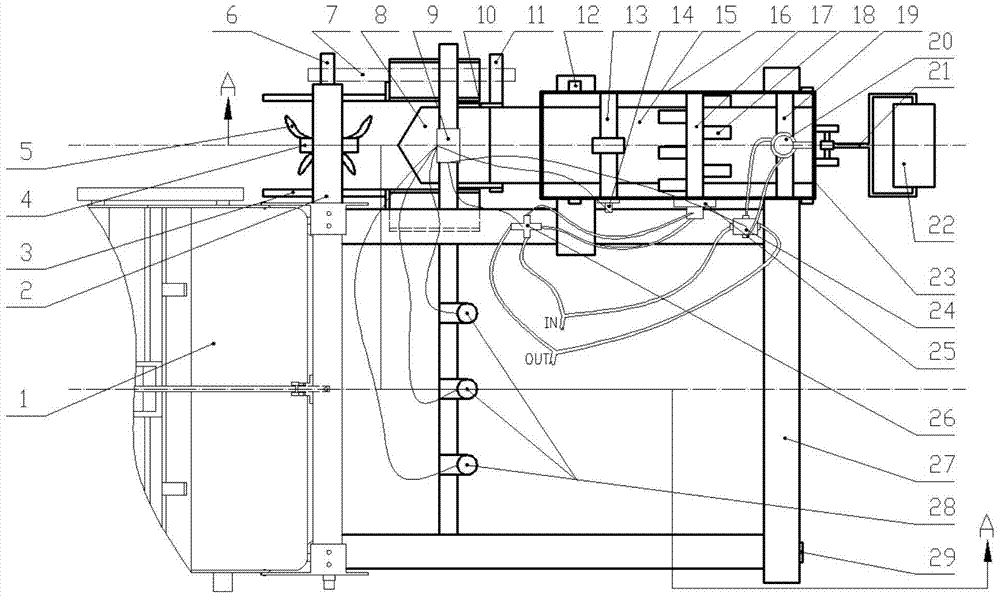

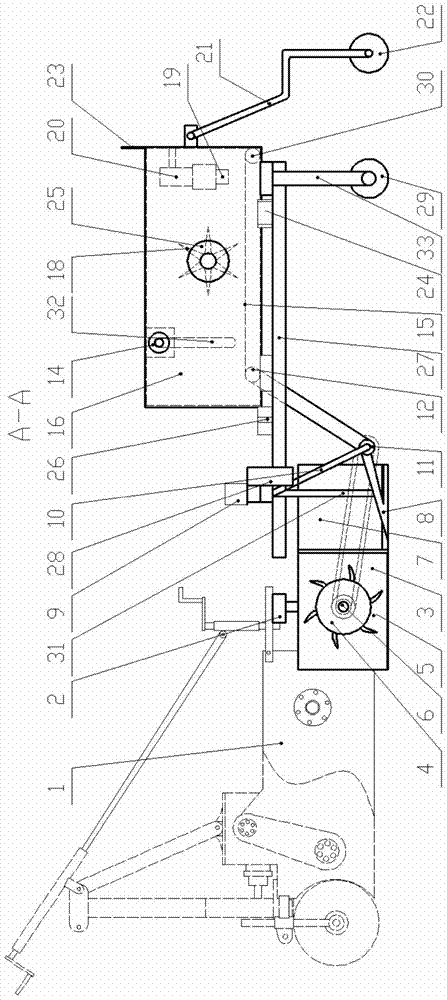

[0037] An intelligent profiling ditch clearing device for a furrow machine in this embodiment, the structure is as follows: figure 1 and figure 2 As shown, it includes the soil-breaking mechanism below the rear crossbeam 2 of the furrow machine 1, the receiving and transporting mechanism supported on the front end of the frame body 27 and placed on the right side of the soil-breaking mechanism, the profiling sensor control mechanism and the soil-breaking mechanism.

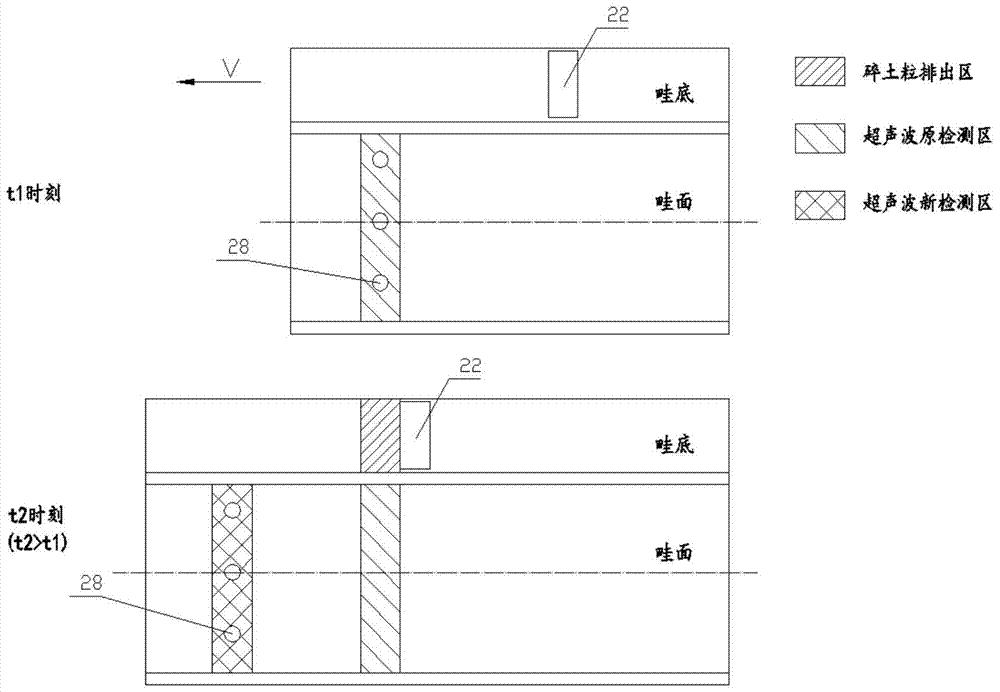

[0038] The signal input terminals of the profiling sensing control mechanism are connected to three groups of ultrasonic sensors 28 located at the middle end of the frame body 27 , and the output terminals are connected to the solenoid valve 24 . The solenoid valve 24 realizes the up and down position of the hydraulic cylinder 20 by controlling the input direction of the hydraulic oil. The upper end of the inner cylinder body of the hydraulic cylinder 20 is fixed integrally with the left side of the movable plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com