Pitch slip ring

A technology of slip rings and conductive rings, which is applied in the direction of current collectors, motor generator connectors, electrical components, etc., and can solve problems such as creepage, reduced creepage distance between brush wire and insulating ring, and unstable contact. Achieve good guiding and limiting effects, improve signal transmission quality, and increase the conductive contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

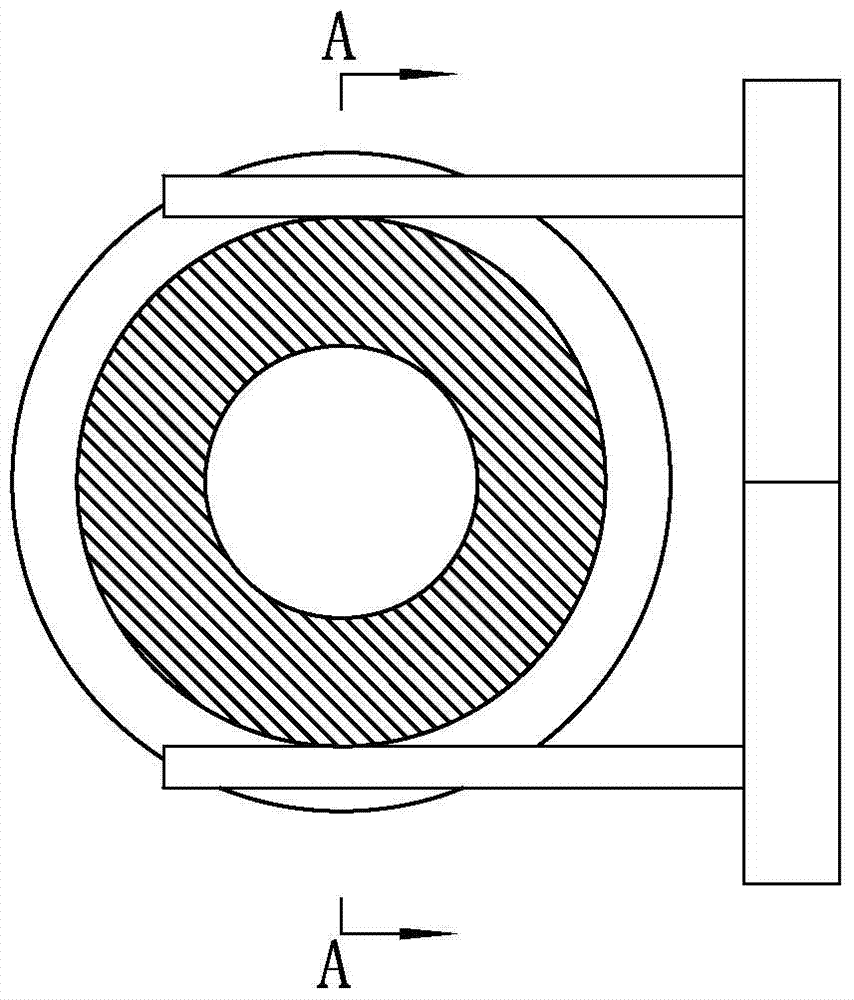

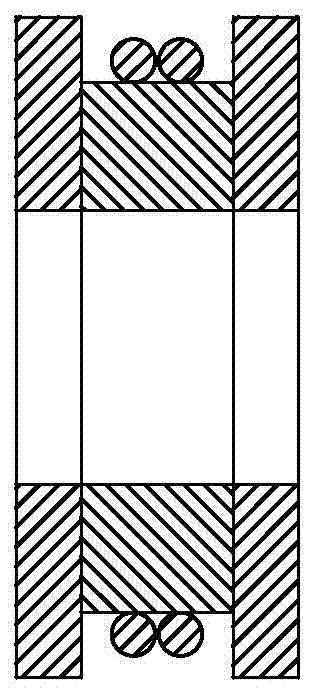

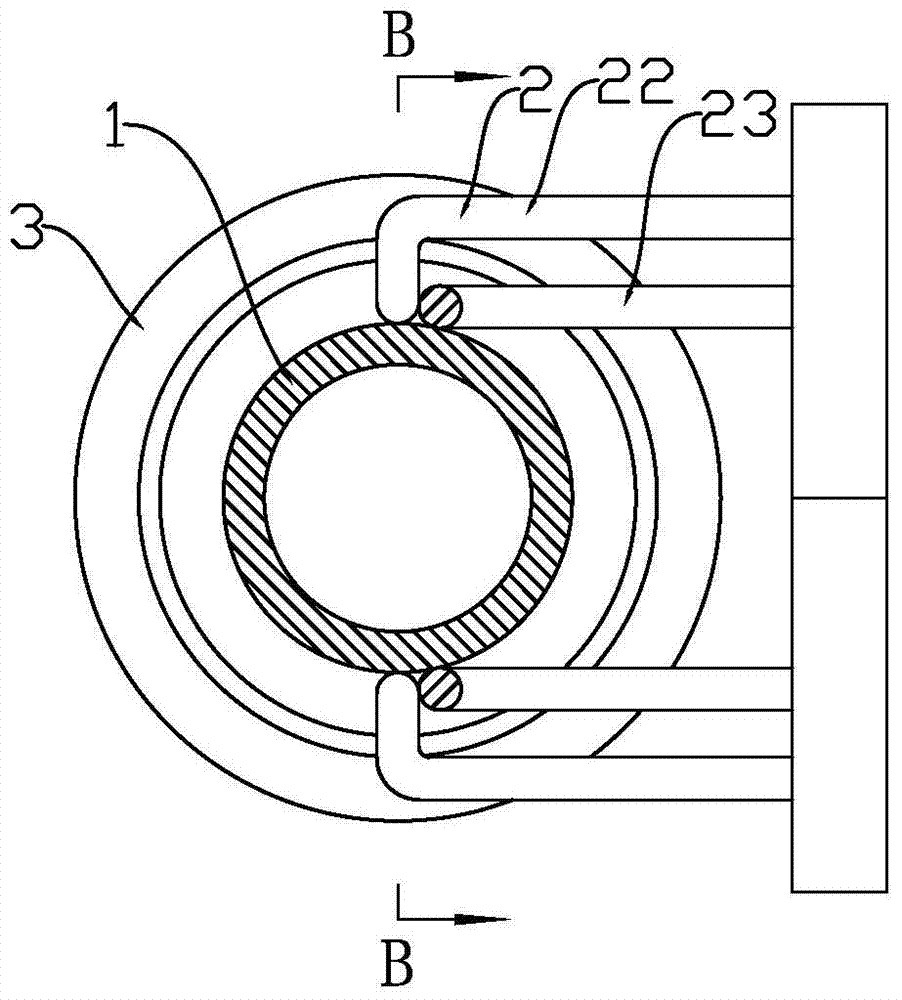

[0016] Such as image 3 and Figure 4 As shown, a pitch slip ring includes a conductive ring 1 and a conductive brush wire 2, an insulating ring 3 is provided on both sides of the conductive ring 1, and a surrounding groove 11 is provided on the outer side of the conductive ring. The end of the brush filament 2 is provided with a brush head 21 that cooperates with the groove 11. The brush head 21 is in line contact or surface contact with the bottom of the groove 11, and the conductive contact area is increased. The original point contact becomes Line contact or surface contact reduces contact resistance and improves signal transmission quality, and the arrangement of the groove 11 prevents the conductive brush wire 2 from contacting the insulating ring 3 and prevents creepage.

[0017] The brush head 21 is a T-shaped brush head, and the inner side of the groove 11 is provided with a limiting protrusion 12 that can limit the T-shaped brush head in the groove 11. Next, the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com