Carbon nanotube coating aluminum foil for power battery and preparation method of carbon nanotube coating aluminum foil

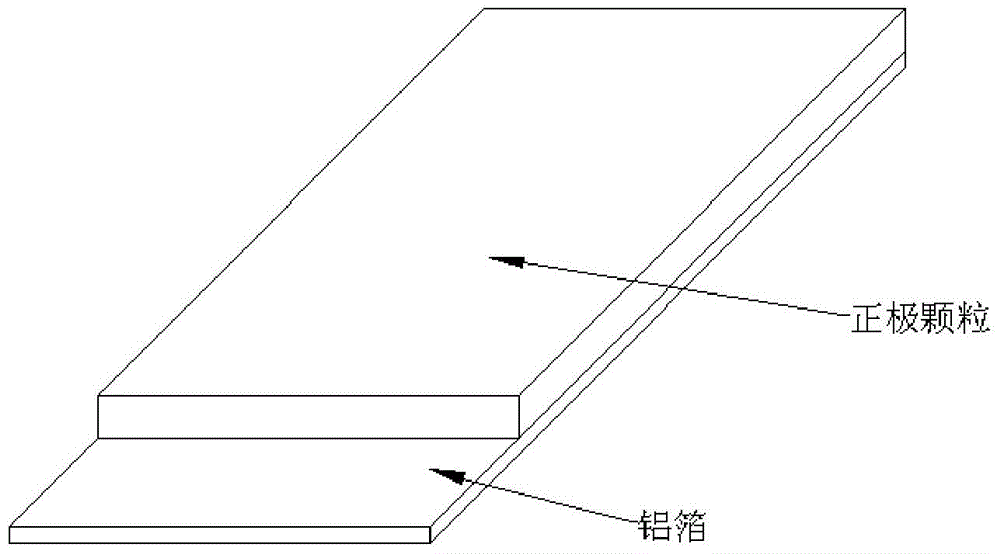

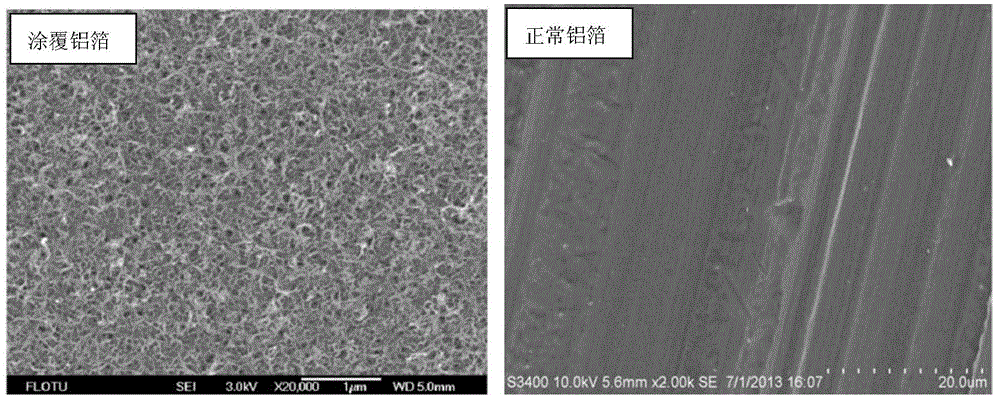

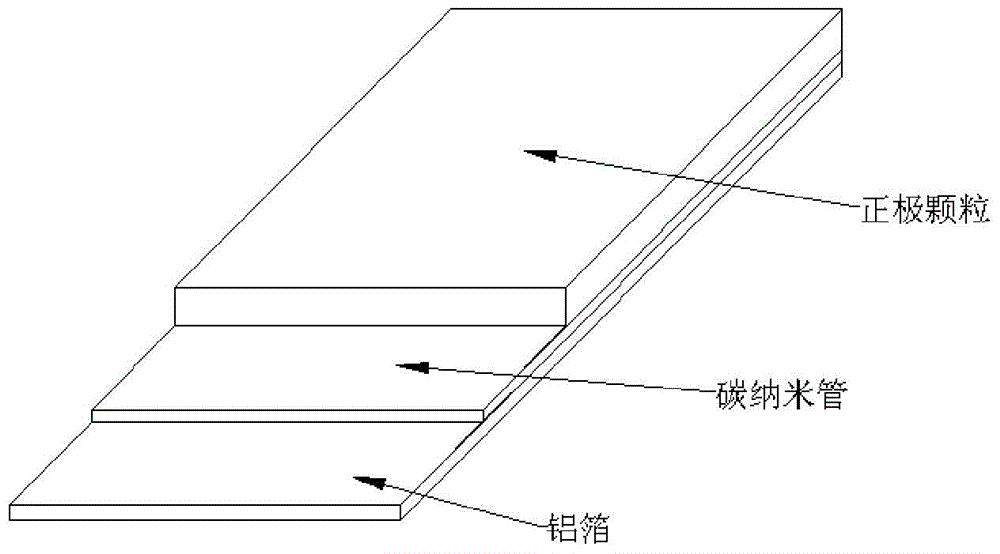

A technology of carbon nanotubes and power batteries, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problem of poor adhesion between positive electrode active materials and aluminum foil, and large DC internal resistance of soft-pack lithium batteries , high current discharge ability and other problems, to achieve the effect of improving the adhesion, increasing the electronic conductive channel and interface contact area, and reducing the DC internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of carbon nanotube-coated aluminum foil for a power battery, the method steps are as follows:

[0031] a. Slurry preparation: according to the ratio shown in Table 1, add the solvent, binder, dispersant, and carbon nanotube powder into the double planetary dispersing equipment in order for mixing and dispersing, and the dispersing time is 2h to 4h; The solvent is nitrogen methyl pyrrolidone, the dispersant is dispersant C500, and the binder is polyvinylidene fluoride;

[0032] b. Slurry performance test: Sampling at the discharge port every 30 minutes, measure the particle size distribution, viscosity, solid content of the slurry and analyze its stability. The viscosity of the slurry does not change more than 5% within 48 hours, and the solid content Enter the next process after the change does not exceed 0.5% within 48 hours;

[0033] c. Coating and drying: Put the above slurry into a high-precision lithium battery coating machine, and the coating...

Embodiment

[0037] Example: Application of a positive carbon nanotube-coated current collector in lithium batteries

[0038] The positive active material is nano LiFePO 4 coated LiNi 0.5 co 0.2 mn 0.3 o 3 (coating amount 10-20%), the positive electrode conductive agent is Super-P, the positive electrode binder is polyvinylidene fluoride; the negative electrode active material is artificial graphite, the negative electrode conductive agent is Super-P, and the negative electrode binder is butyl styrene Rubber, the negative electrode thickener is sodium carboxymethyl cellulose, the positive electrode current collector is the above-mentioned carbon nanotube coated aluminum foil, and the negative electrode current collector is double-light copper foil. The electrolyte is a combined solvent system of ethylene carbonate, propylene carbonate and dimethyl carbonate added with lithium hexafluorophosphate. Separator is Al 2 o 3 Coated with PE diaphragm. The battery cell adopts a Z-shaped lam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com